3 Application Examples

3.1 Introduction

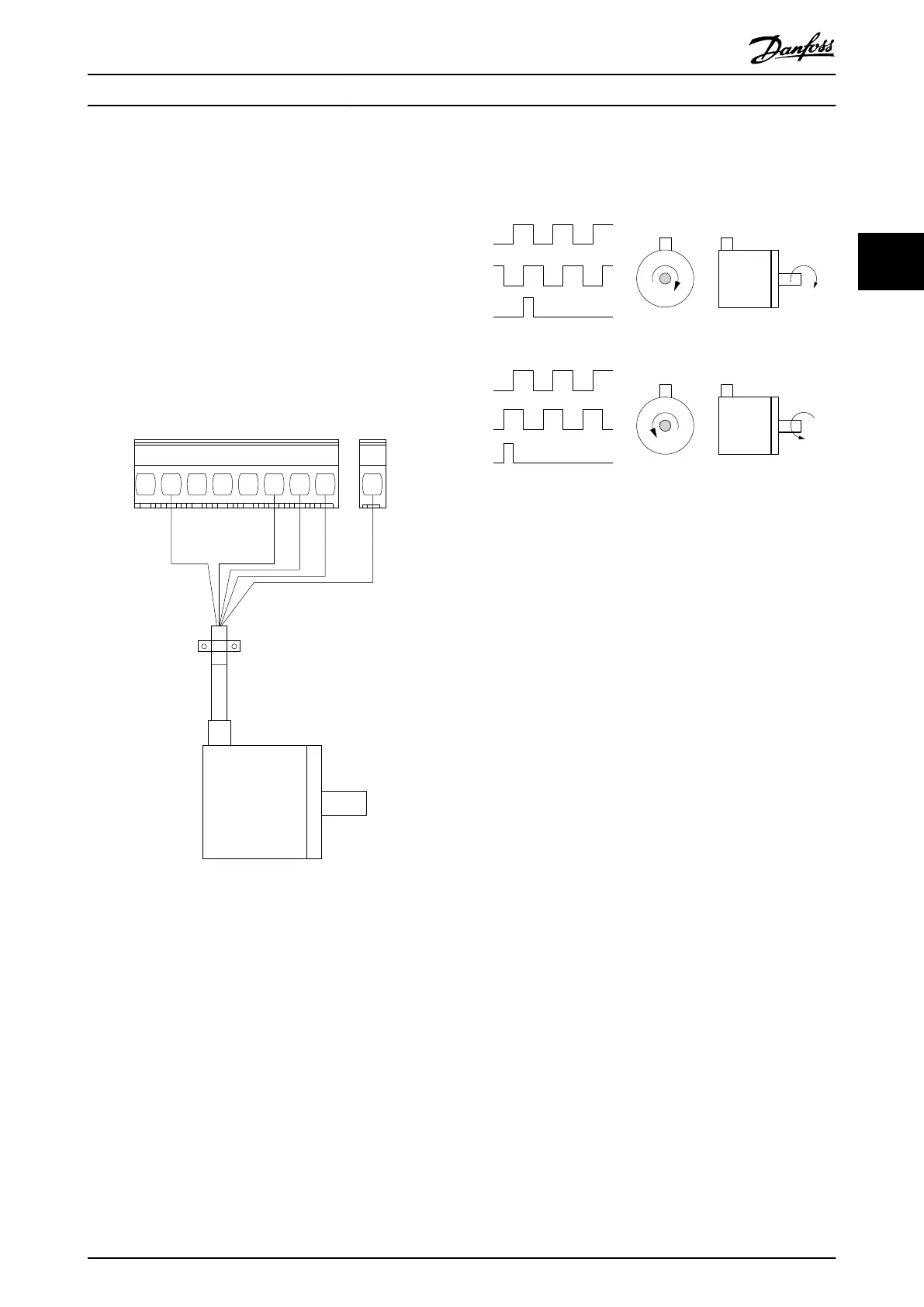

3.1.1 Encoder Connection

The purpose of this guideline is to ease the set-up of

encoder connection to the frequency converter. Before

setting up the encoder, the basic settings for a closed-loop

speed control system are shown.

130BE805.10

+24 V DC

+24 V DC

A

B

Z

GND

12 13 18 19 3227 29 33 55

Illustration 3.1 24 V Encoder

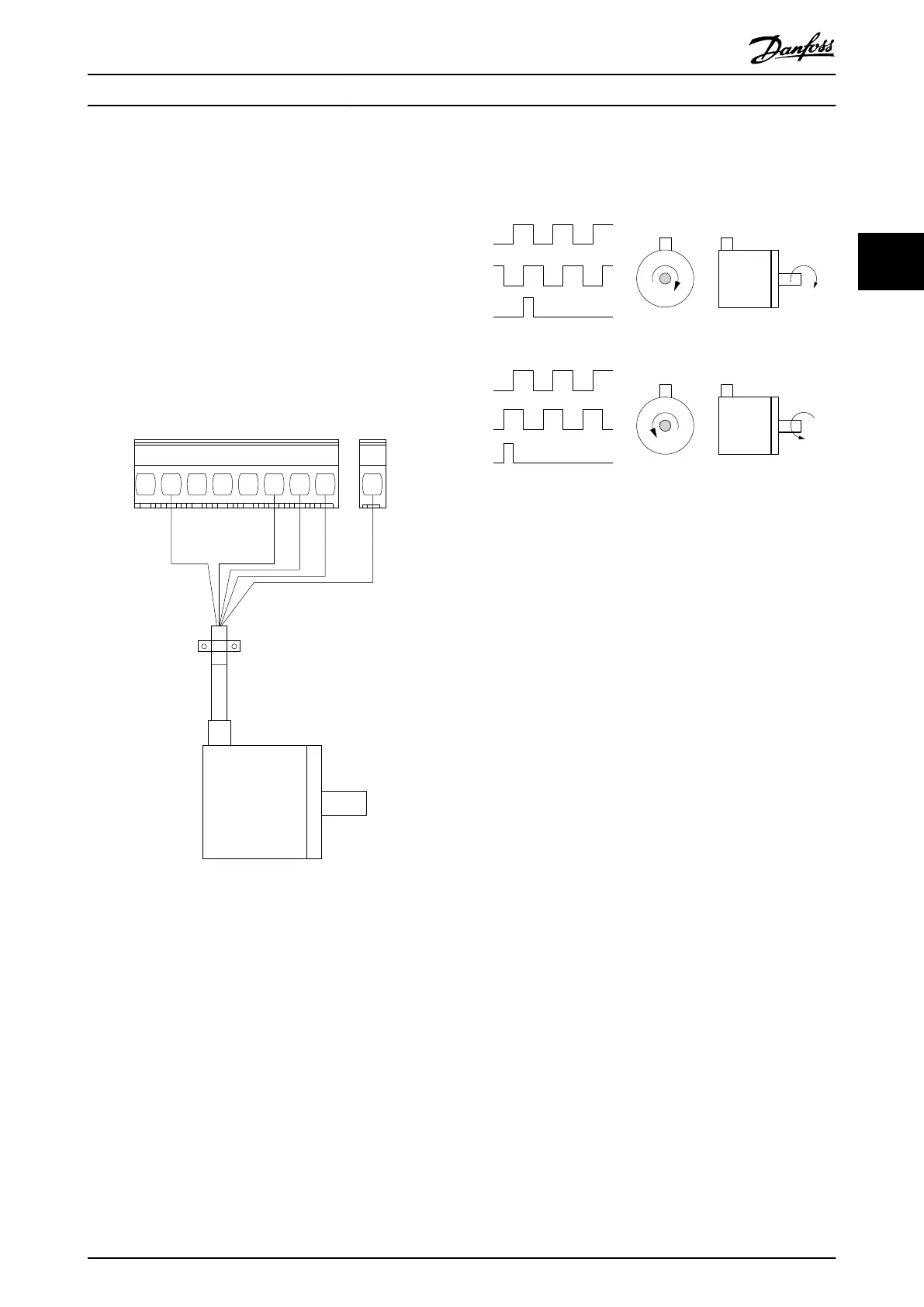

Illustration 3.2 24 V Incremental Encoder, Maximum Cable

Length 5 m (16.4 ft)

3.1.2 Encoder Direction

The order in which the pulses enter the frequency

converter determines the direction of the encoder.

Clockwise direction means that channel A is 90 electrical

degrees before channel B.

Counterclockwise direction means that channel B is 90

electrical degrees before A.

The direction is determined by looking into the shaft end.

3.1.3 Closed-loop Drive System

A drive system usually consists of more elements such as:

•

Motor.

•

Brake (gearbox, mechanical brake).

•

Frequency converter.

•

Encoder as feedback system.

•

Brake resistor for dynamic brake.

•

Transmission.

•

Load.

Applications demanding mechanical brake control usually

need a brake resistor.

Application Examples Design Guide

MG07B102 Danfoss A/S © 03/2016 All rights reserved. 45

3 3

Loading...

Loading...