2.6.3 EMC Immunity Requirements

The immunity requirements for frequency converters depend on the environment in which they are installed. The

requirements for the industrial environment are higher than the requirements for the home and oce environment. All

Danfoss frequency converters comply with the requirements for the industrial environment. Therefore, they also comply with

the lower requirements for home and oce environment with a large safety margin.

To document immunity against burst transient from electrical phenomena, the following immunity tests have been made on

a system consisting of:

•

A frequency converter (with options if relevant)

•

A shielded control cable

•

A control box with potentiometer, motor cable, and motor.

The tests were performed in accordance with the following basic standards:

•

EN 61000-4-2 (IEC 61000-4-2) Electrostatic discharges (ESD): Simulation of electrostatic discharges from human

beings.

•

EN 61000-4-3 (IEC 61000-4-3) Radiated immunity: Amplitude modulated simulation of the

eects of radar and

radio communication equipment and mobile communications equipment.

•

EN 61000-4-4 (IEC 61000-4-4) Burst transients: Simulation of interference caused by switching a contactor, relay,

or similar devices.

•

EN 61000-4-5 (IEC 61000-4-5) Surge transients: Simulation of transients caused by, for example, lightning that

strikes near installations.

•

EN 61000-4-6 (IEC 61000-4-6) Conducted immunity: Simulation of the

eect from radio-transmission equipment

joined by connection cables.

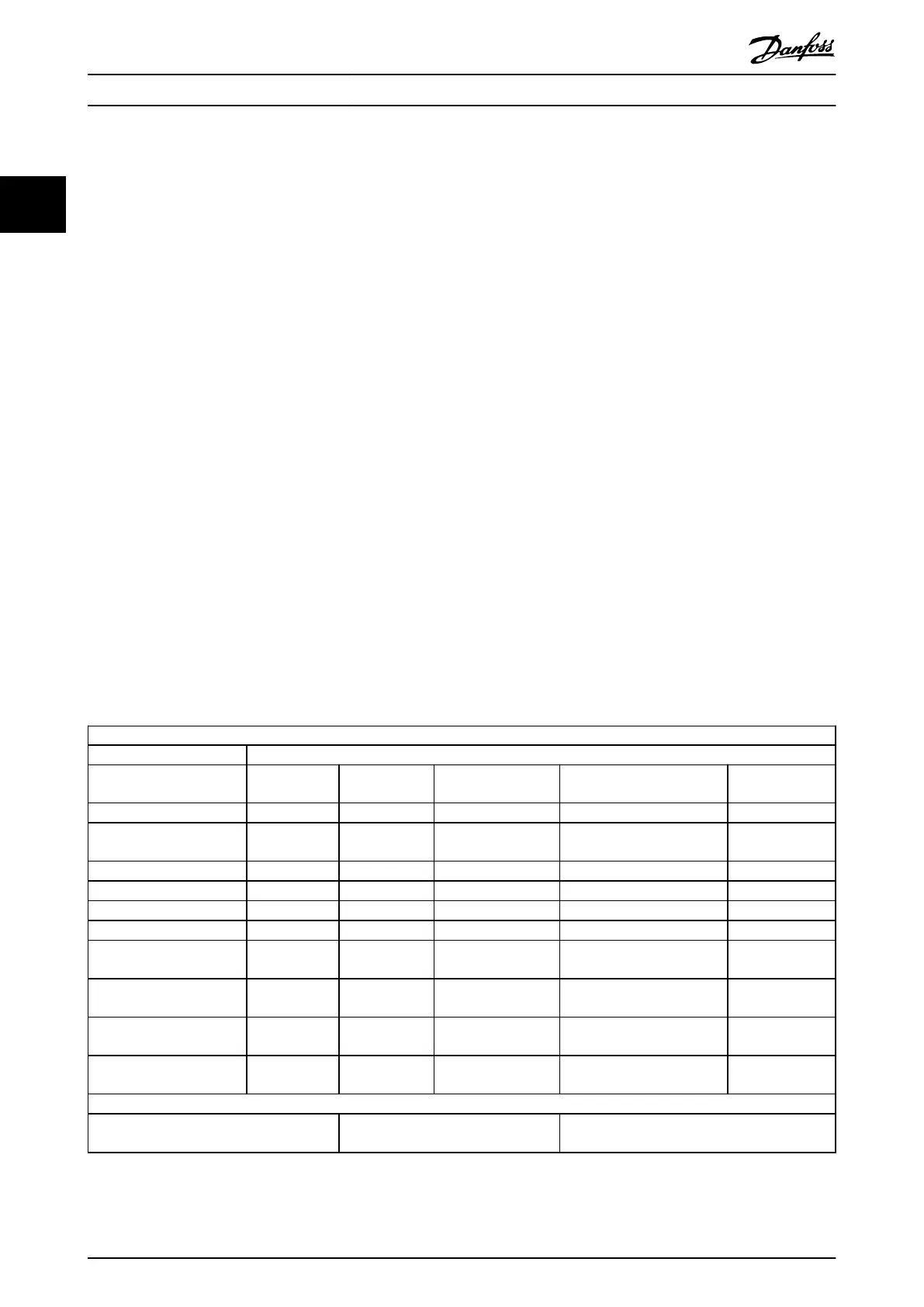

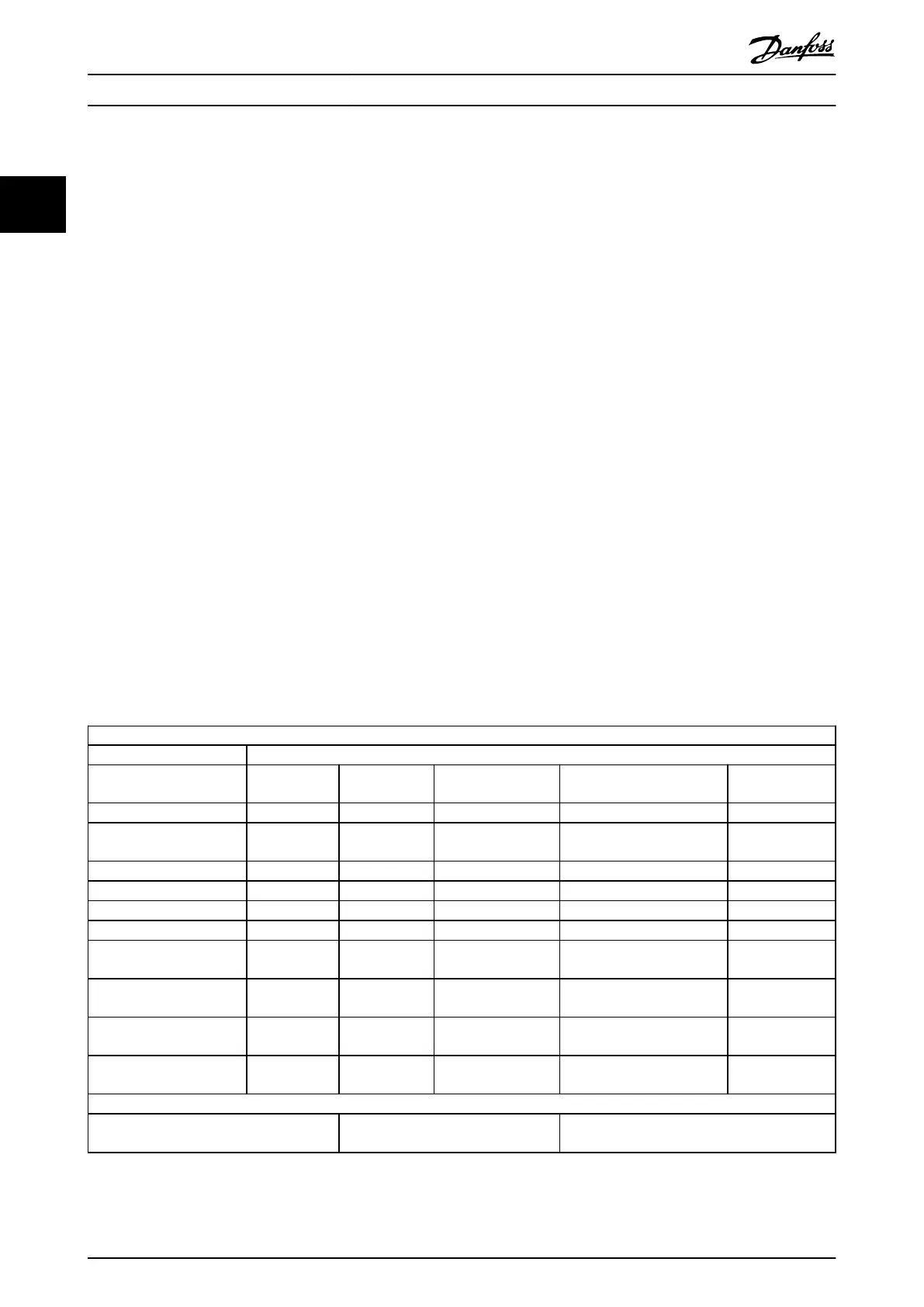

The immunity requirements should follow product standard IEC 61800-3 and Danfoss internal standards. See Table 2.13 for

details.

Voltage range: 380–480 V

Product standard 61800-3

Test

ESD Radiated

immunity

Burst Surge Conducted

immunity

Acceptance criterion B B B A A

Mains cable – – 2 kV CN

2 kV/2 Ω DM

2 kV/12 Ω CM

10 V

RMS

Motor cable – – 4 kV CCC – 10 V

RMS

Brake cable – – 4 kV CCC – 10 V

RMS

Load sharing cable – – 4 kV CCC – 10 V

RMS

Relay cable – – 4 kV CCC – 10 V

RMS

Control cable – –

Length >2 m (6.6 ft)

1 kV CCC

Unshielded:

1 kV/42 Ω CM

10 V

RMS

Standard/eldbus cable – –

Length >2 m (6.6 ft)

1 kV CCC

Unshielded:

1 kV/42 Ω CM

10 V

RMS

LCP cable – –

Length >2 m (6.6 ft)

1 kV CCC

– 10 V

RMS

Enclosure

4 kV CD

8 kV AD

10 V/m – – –

Denitions

CD: Contact discharge

AD: Air discharge

DM: Dierential mode

CM: Common mode

CN: Direct injection through coupling network

CCC: Injection through capacitive coupling clamp

Table 2.13 EMC Immunity Requirements

Product Overview

VLT

®

Midi Drive FC 280

38 Danfoss A/S © 03/2016 All rights reserved. MG07B102

22

Loading...

Loading...