2.9.2 Dynamic Braking

Dynamic braking is established by:

•

Resistor brake: A brake IGBT keeps the

overvoltage under a certain threshold by

directing the brake energy from the motor to the

connected brake resistor (parameter 2-10 Brake

Function = [1] Resistor brake).

Adjust the threshold in parameter 2-14 Brake

voltage reduce, with 70 V range for 3x380–480 V.

•

AC brake: The brake energy is distributed in the

motor by changing the loss conditions in the

motor. The AC brake function cannot be used in

applications with high cycling frequency as this

overheats the motor (parameter 2-10 Brake

Function = [2] AC brake).

•

DC brake: An overmodulated DC current added to

the AC current works as an eddy current brake

(parameter 2-02 DC Braking Time≠0 s).

2.9.3 Brake Resistor Selection

To handle higher demands by generatoric braking, a brake

resistor is necessary. Using a brake resistor ensures that the

heat is absorbed in the brake resistor and not in the

frequency converter. For more information, see the VLT

®

Brake Resistor MCE 101 Design Guide.

If the amount of kinetic energy transferred to the resistor

in each braking period is not known, calculate the average

power based on the cycle time and braking time. The

resistor intermittent duty cycle is an indication of the duty

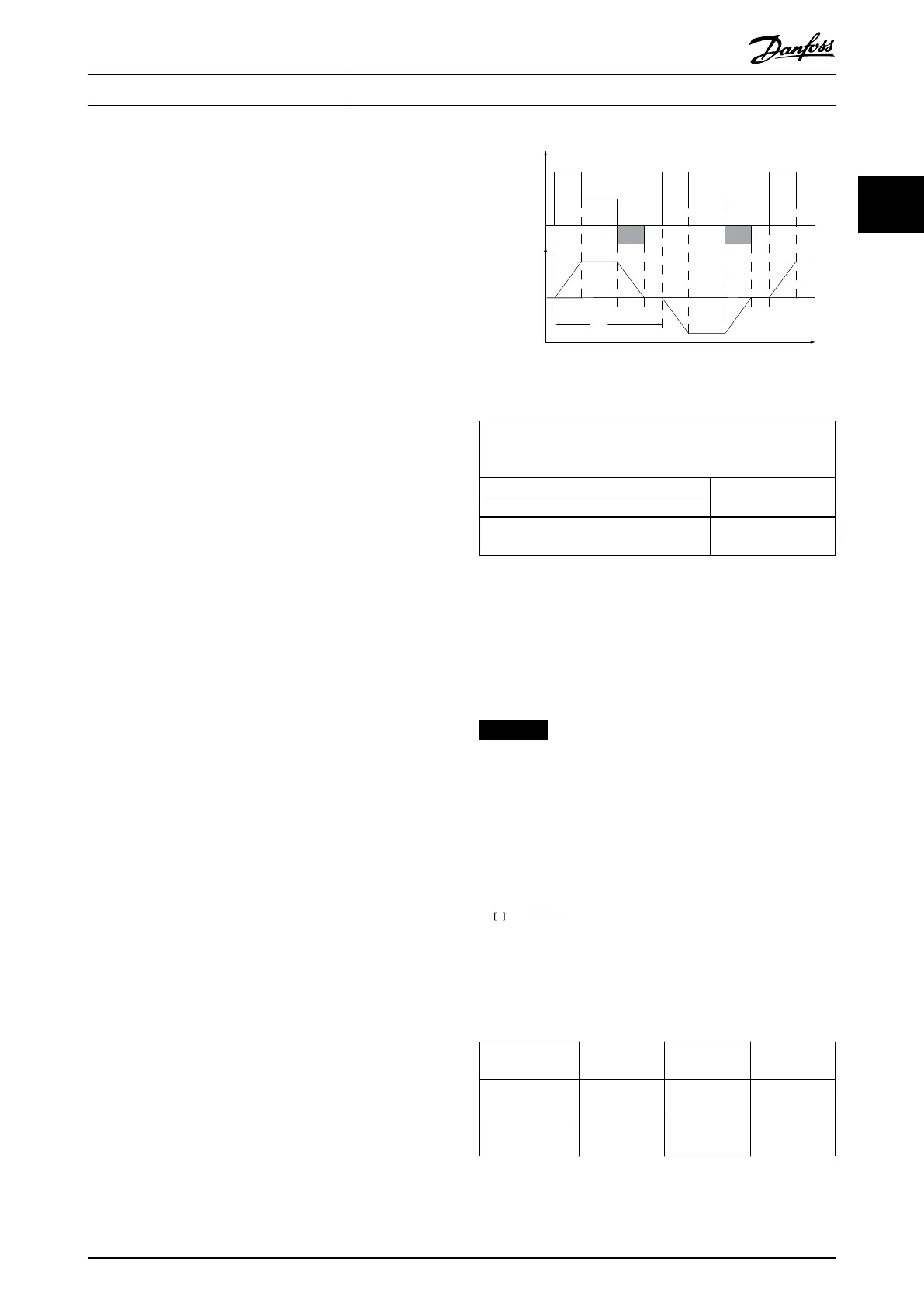

cycle at which the resistor is active. Illustration 2.32 shows a

typical braking cycle.

The intermittent duty cycle for the resistor is calculated as

follows:

Duty cycle = t

b

/T

t

b

is the braking time in seconds.

T = cycle time in seconds.

T

ta

tc

tb

to ta

tc

tb

to ta

130BA167.10

Load

Time

Speed

Illustration 2.32 Typical Braking Cycle

Power range:

0.37–22 kW (0.5–30 hp) 3x380–480 V

0.37–3.7 kW (0.5–5 hp) 3x200–240 V

Cycle time (s) 120

Braking duty cycle at 100% torque Continuous

Braking duty cycle at overtorque

(150/160%)

40%

Table 2.14 Braking at High Overload Torque Level

Danfoss oers brake resistors with duty cycles of 10% and

40%. If a 10% duty cycle is applied, the brake resistors are

able to absorb brake power for 10% of the cycle time. The

remaining 90% of the cycle time is used for dissipating

excess heat.

NOTICE

Make sure that the resistor is designed to handle the

required braking time.

The maximum allowed load on the brake resistor is stated

as a peak power at a given intermittent duty cycle and can

be calculated as:

Brake resistance calculation

R

br

Ω =

U

dc,br

2

x0 . 83

P

peak

where

P

peak

= P

motor

x M

br

[%] x η

motor

x η

VLT

[W]

As shown, the brake resistance depends on the DC-link

voltage (U

dc

).

Size Brake active

U

dc,br

Warning

before cutout

Cutout (trip)

FC 280

3x380–480 V

770 V 800 V 800 V

FC 280

3x200–240 V

390 V 410 V 410 V

Table 2.15 Threshold of the Brake Resistance

Product Overview Design Guide

MG07B102 Danfoss A/S © 03/2016 All rights reserved. 41

2 2

Loading...

Loading...