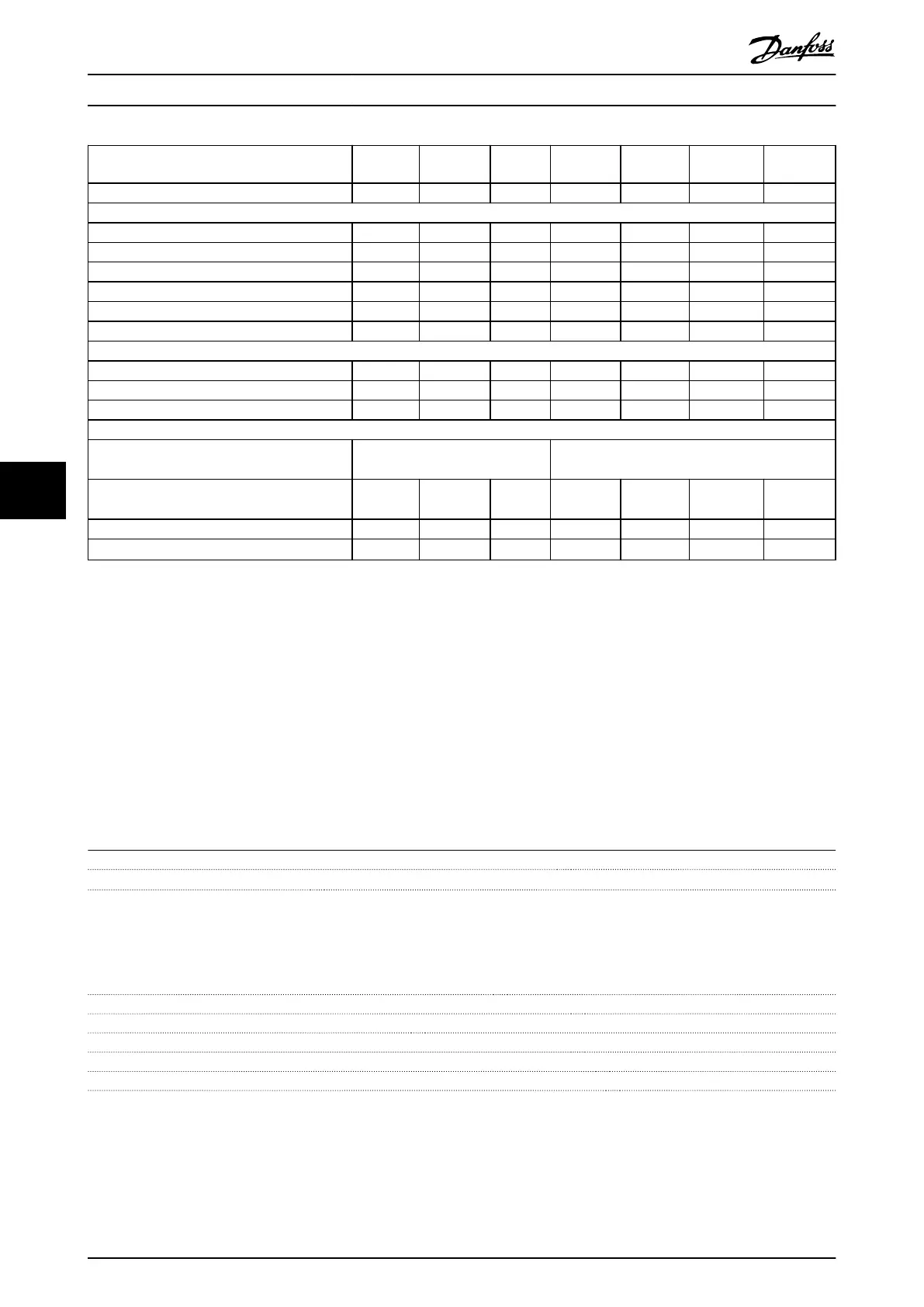

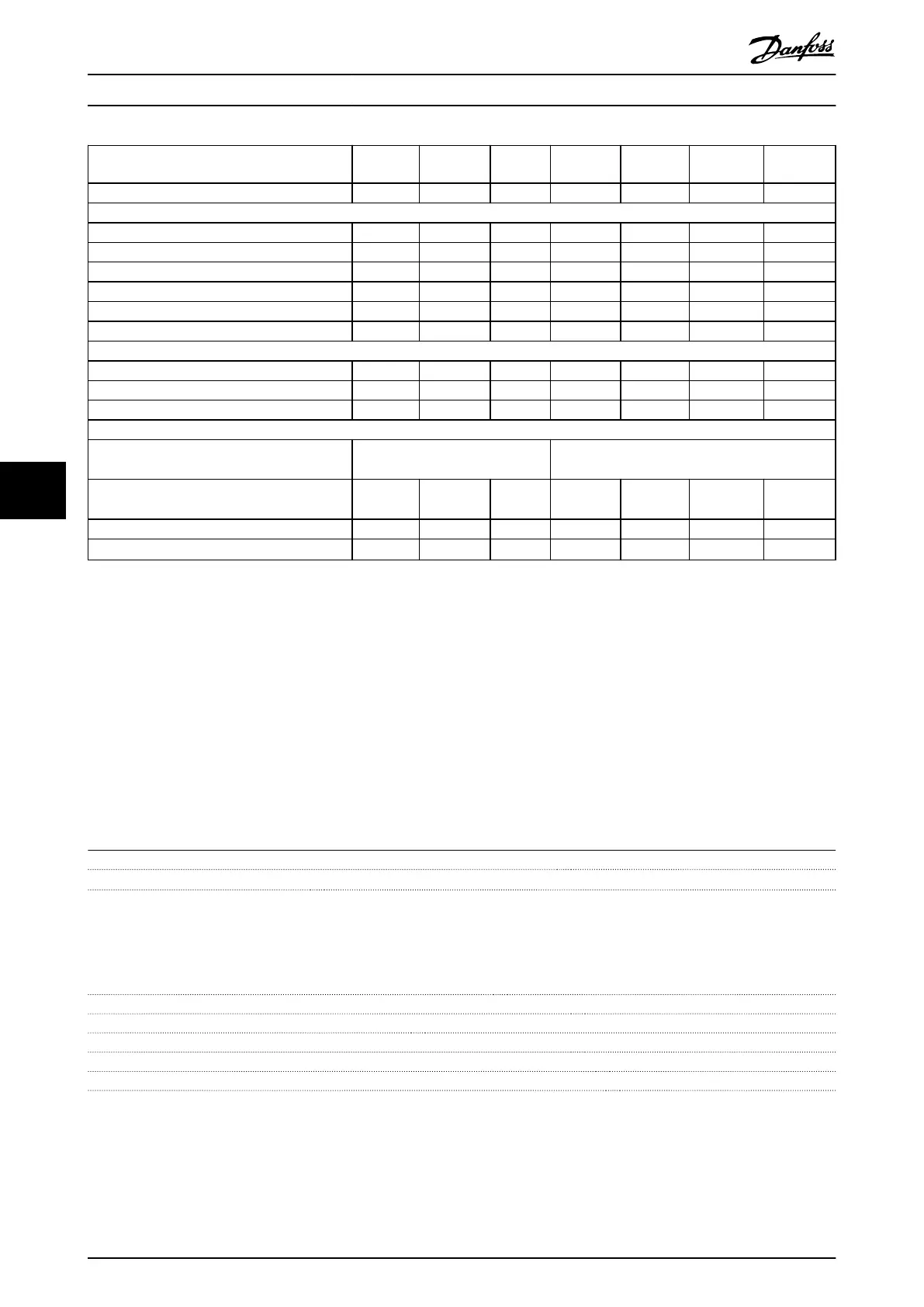

Frequency converter

typical shaft output [kW]

P4K0

4

P5K5

5.5

P7K5

7.5

P11K

11

P15K

15

P18K

18.5

P22K

22

Enclosure protection rating IP20 K2 K2 K3 K4 K4 K5 K5

Output current

Shaft output 4 5.5 7.5 11 15 18.5 22

Continuous (3x380–440 V) [A] 9 12 15.5 23 31 37 42.5

Continuous (3x441–480 V) [A] 8.2 11 14 21 27 34 40

Intermittent (60 s overload) [A] 14.4 19.2 24.8 34.5 46.5 55.5 63.8

Continuous kVA (400 V AC) [kVA] 6.2 8.3 10.7 15.9 21.5 25.6 29.5

Continuous kVA (480 V AC) [kVA] 6.8 9.1 11.6 17.5 22.4 28.3 33.3

Maximum input current

Continuous (3x380–440 V) [A] 8.3 11.2 15.1 22.1 29.9 35.2 41.5

Continuous (3x441–480 V) [A] 6.8 9.4 12.6 18.4 24.7 29.3 34.6

Intermittent (60 s overload) [A] 13.3 17.9 24.2 33.2 44.9 52.8 62.3

More specications

Maximum cable size (mains, motor, brake)

[mm

2

(AWG)]

4(12) 16(6)

Estimated power loss at rated maximum load

[W]

1)

115.5 157.5 192.8 289.5 393.4 402.8 467.5

Weight enclosure protection rating IP20 [kg (lb)] 3.6 (7.9) 3.6 (7.9) 4.1 (9.0) 9.4 (20.7) 9.5 (20.9) 12.3 (27.1) 12.5 (27.6)

Eciency [%]

2)

97.6 97.7 98.0 97.8 97.8 98.1 97.9

Table 7.2 Mains Supply 3x380–480 V AC

1) The typical power loss is at nominal load conditions and expected to be within

±

15% (tolerance relates to variety in voltage and cable

conditions).

Values are based on a typical motor eciency (IE2/IE3 border line). Motors with lower eciency add to the power loss in the frequency converter,

and motors with high eciency reduce power loss.

Applies to dimensioning of frequency converter cooling. If the switching frequency is higher than the default setting, the power losses sometimes

rise. LCP and typical control card power consumptions are included. Further options and customer load sometimes add up to 30 W to the losses

(though typically only 4 W extra for a fully loaded control card or eldbus).

For power loss data according to EN 50598-2, refer to www.danfoss.com/vltenergyeciency.

2) Measured using 50 m (164 ft) shielded motor cables at rated load and rated frequency. For energy eciency class, see chapter 7.4 Ambient

Conditions. For part load losses, see www.danfoss.com/vltenergyeciency.

7.2

Mains Supply (3-phase)

Mains supply (L1, L2, L3)

Supply terminals L1, L2, L3

Supply voltage 380–480 V: -15% (-25%)

1)

to +10%

1) The frequency converter can run at -25% input voltage with reduced performance. The maximum output power of the

frequency converter is 75% if input voltage is -25%, and 85% if input voltage is -15%.

Full torque cannot be expected at mains voltage lower than 10% below the lowest rated supply voltage of the frequency

converter.

Supply frequency 50/60 Hz ±5%

Maximum imbalance temporary between mains phases 3.0% of rated supply voltage

True power factor (λ) ≥0.9 nominal at rated load

Displacement power factor (cos ϕ) Near unity (>0.98)

Switching on input supply L1, L2, L3 (power-ups) ≤7.5 kW Maximum 2 times/minute

Switching on input supply L1, L2, L3 (power-ups) 11–22 kW Maximum 1 time/minute

The unit is suitable for use on a circuit capable of delivering less than 5000 RMS symmetrical Amperes, 480 V maximum.

Specications

VLT

®

Midi Drive FC 280

76 Danfoss A/S © 03/2016 All rights reserved. MG07B102

77

Loading...

Loading...