2.7 Galvanic Isolation

PELV oers protection through extra low voltage.

Protection against electric shock is ensured when the

electrical supply is of the PELV type and the installation is

made as described in local/national regulations on PELV

supplies.

All control terminals and relay terminals 01–03 comply

with PELV (protective extra low voltage). This does not

apply to grounded Delta leg above 400 V.

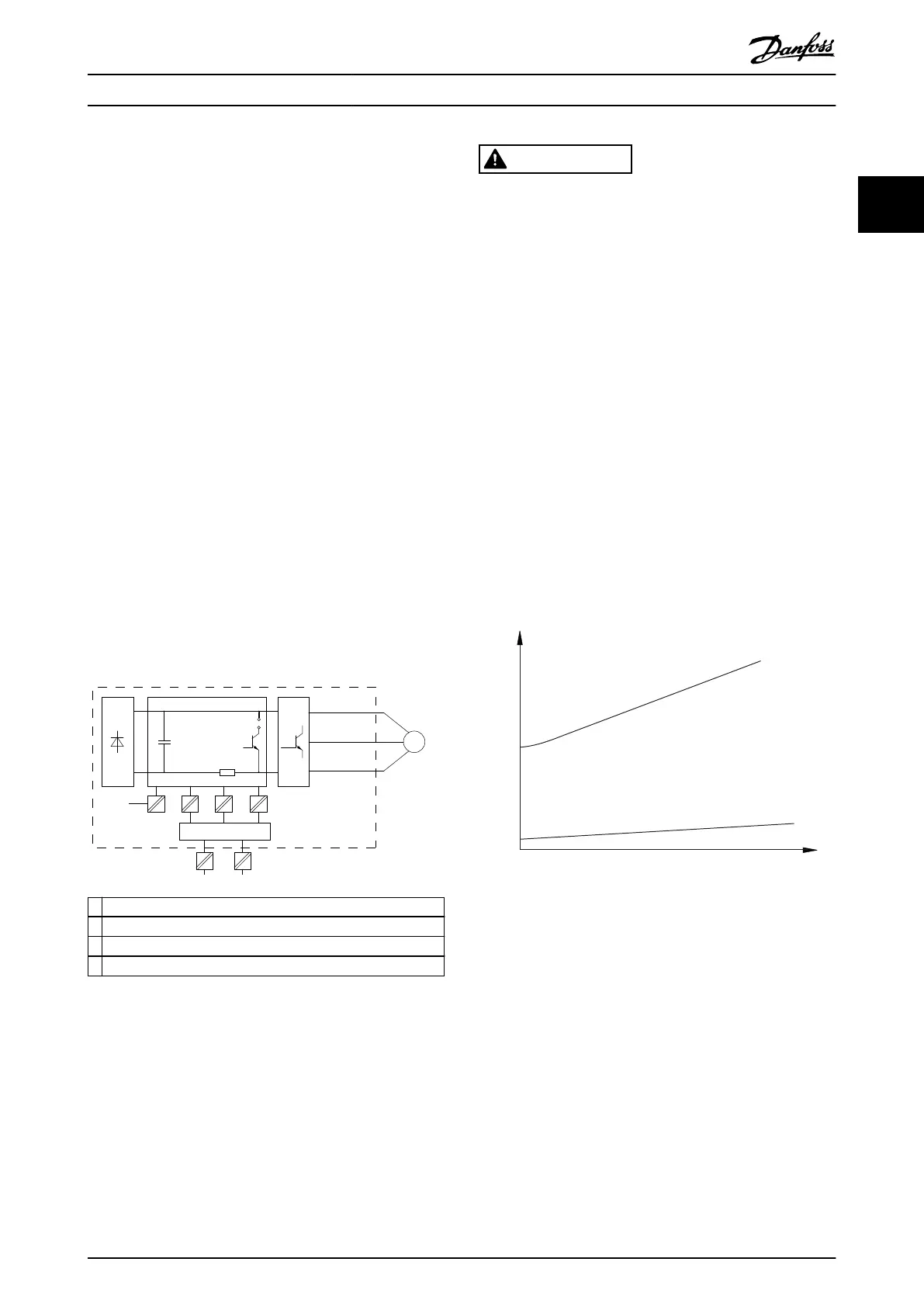

Galvanic (ensured) isolation is obtained by fullling

requirements for higher isolation and by providing the

relevant creapage/clearance distances. These requirements

are described in the EN 61800-5-1 standard.

The components that make up the electrical isolation, as

shown in Illustration 2.27, also comply with the

requirements for higher isolation and the relevant test as

described in EN 61800-5-1.

The PELV galvanic isolation can be shown in 3 locations

(see Illustration 2.27):

To maintain PELV, all connections made to the control

terminals must be PELV, for example, the thermistor must

be reinforced/double insulated.

1 Power supply (SMPS) for control cassette

2 Communication between power card and control cassette

3 Isolation between STO inputs and IGBT circuit

4 Customer relay

Illustration 2.27 Galvanic Isolation

The functional galvanic isolation (a and b on

Illustration 2.27) is for the 24 V back-up option and the

RS485 standard bus interface.

WARNING

Before touching any electrical parts, ensure that other

voltage inputs have been disconnected, such as load

sharing (linkage of DC intermediate circuit) and the

motor connection for kinetic back-up. Observe the

discharge time stated in chapter Safety in the VLT

®

Midi

Drive FC 280 Operating Guide. Failure to follow

recommendations could result in death or serious injury.

2.8 Ground Leakage Current

Follow national and local codes regarding protective

grounding of equipment with a leakage current >3.5 mA.

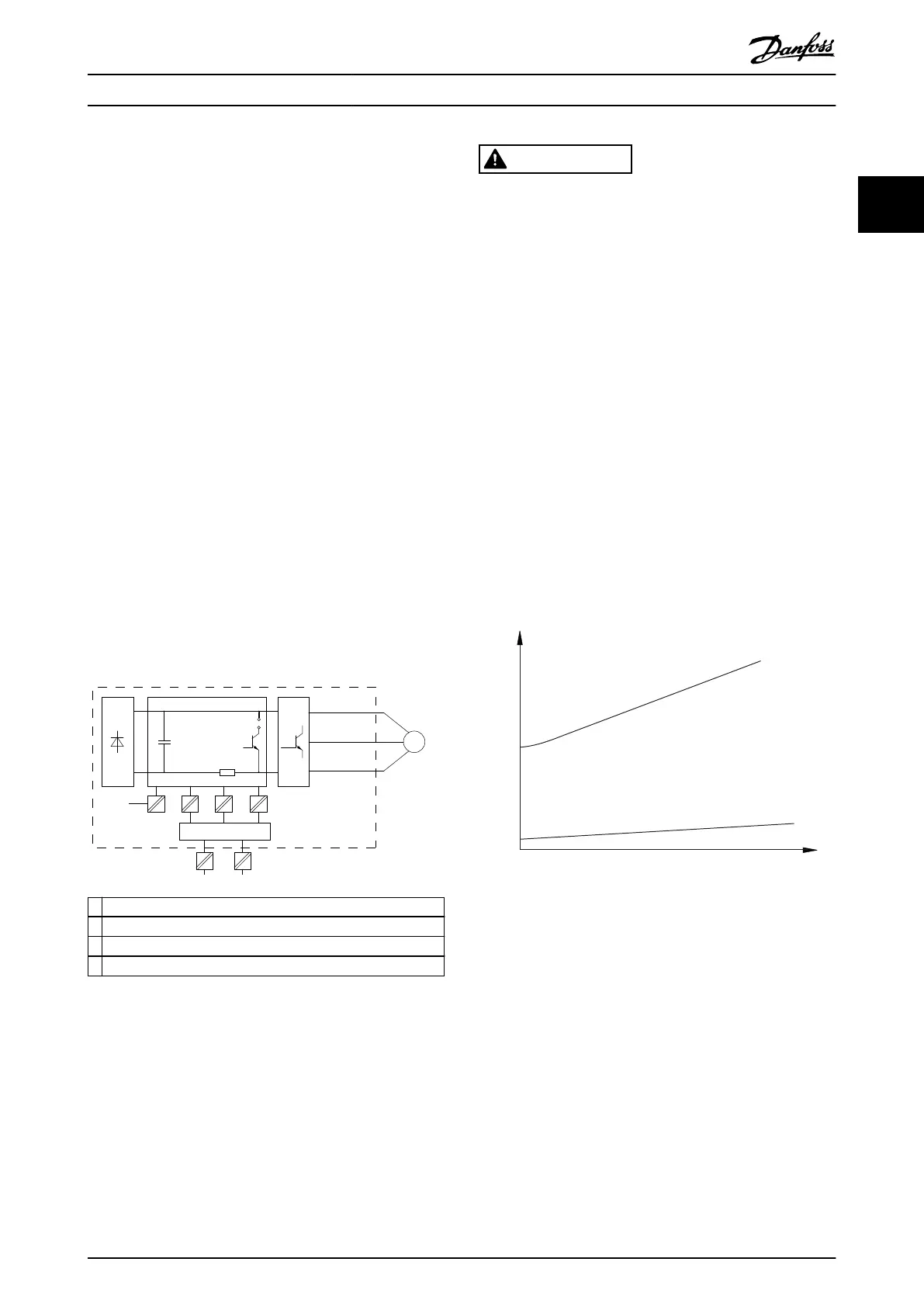

Frequency converter technology implies high frequency

switching at high power. This switching generates a

leakage current in the ground connection. A fault current

in the frequency converter at the output power terminals

might contain a DC component, which can charge the

lter capacitors and cause a transient ground current.

The ground leakage current is made up of several contri-

butions and depends on various system congurations

including RFI ltering, shielded motor cables, and

frequency converter power.

130BB955.12

a

b

Leakage current

Motor cable length

Illustration 2.28 Inuence the Cable Length and Power Size on

Leakage Current, P

a

>P

b

Product Overview Design Guide

MG07B102 Danfoss A/S © 03/2016 All rights reserved. 39

2 2

Loading...

Loading...