5.6 Modbus RTU

5.6.1 Prerequisite Knowledge

Danfoss assumes that the installed controller supports the

interfaces in this manual, and strictly observes all

requirements and limitations stipulated in the controller

and frequency converter.

The built-in Modbus RTU (remote terminal unit) is

designed to communicate with any controller that

supports the interfaces dened in this manual. It is

assumed that the user has full knowledge of the

capabilities and limitations of the controller.

5.6.2 Overview

Regardless of the type of physical communication

networks, this section describes the process a controller

uses to request access to another device. This process

includes how the Modbus RTU responds to requests from

another device, and how errors are detected and reported.

It also establishes a common format for the layout and

contents of telegram elds.

During communications over a Modbus RTU network, the

protocol:

•

Determines how each controller learns its device

address.

•

Recognizes a telegram addressed to it.

•

Determines which actions to take.

•

Extracts any data or other information contained

in the telegram.

If a reply is required, the controller constructs the reply

telegram and sends it.

Controllers communicate using a master/slave technique in

which only the master can initiate transactions (called

queries). Slaves respond by supplying the requested data

to the master, or by acting as requested in the query.

The master can address individual slaves, or initiate a

broadcast telegram to all slaves. Slaves return a response

to queries that are addressed to them individually. No

responses are returned to broadcast queries from the

master.

The Modbus RTU protocol establishes the format for the

master query by providing the following information:

•

The device (or broadcast) address.

•

A function code dening the requested action.

•

Any data to be sent.

•

An error-checking eld.

The response telegram of the slave device is also

constructed using Modbus protocol. It contains elds

conrming the action taken, any data to be returned, and

an error-checking eld. If an error occurs in receipt of the

telegram, or if the slave is unable to perform the requested

action, the slave constructs and sends an error message.

Alternatively, a timeout occurs.

5.6.3 Frequency Converter with Modbus

RTU

The frequency converter communicates in Modbus RTU

format over the built-in RS485 interface. Modbus RTU

provides access to the control word and bus reference of

the frequency converter.

The control word allows the Modbus master to control

several important functions of the frequency converter:

•

Start.

•

Various stops:

- Coast stop.

- Quick stop.

- DC brake stop.

- Normal (ramp) stop.

•

Reset after a fault trip.

•

Run at various preset speeds.

•

Run in reverse.

•

Change the active set-up.

•

Control built-in relay of the frequency converter.

The bus reference is commonly used for speed control. It is

also possible to access the parameters, read their values,

and, where possible, write values to them. Accessing the

parameters

oers a range of control options, including

controlling the setpoint of the frequency converter when

its internal PI controller is used.

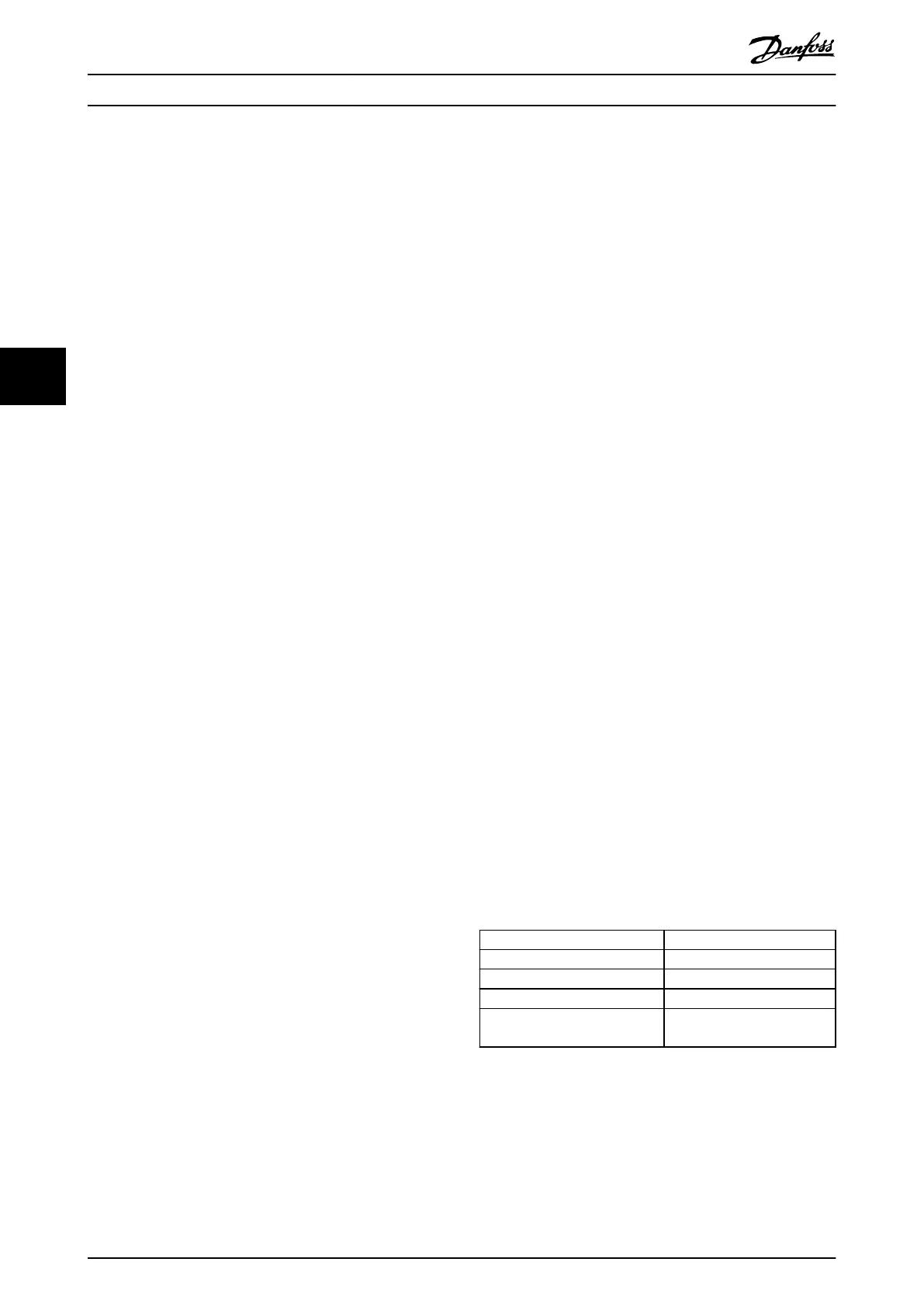

5.7

Network Conguration

To enable Modbus RTU on the frequency converter, set the

following parameters:

Parameter Setting

Parameter 8-30 Protocol Modbus RTU

Parameter 8-31 Address 1–247

Parameter 8-32 Baud Rate 2400–115200

Parameter 8-33 Parity / Stop Bits Even parity, 1 stop bit

(default)

Table 5.11 Network Conguration

RS485 Installation and Set-...

VLT

®

Midi Drive FC 280

60 Danfoss A/S © 03/2016 All rights reserved. MG07B102

55

Loading...

Loading...