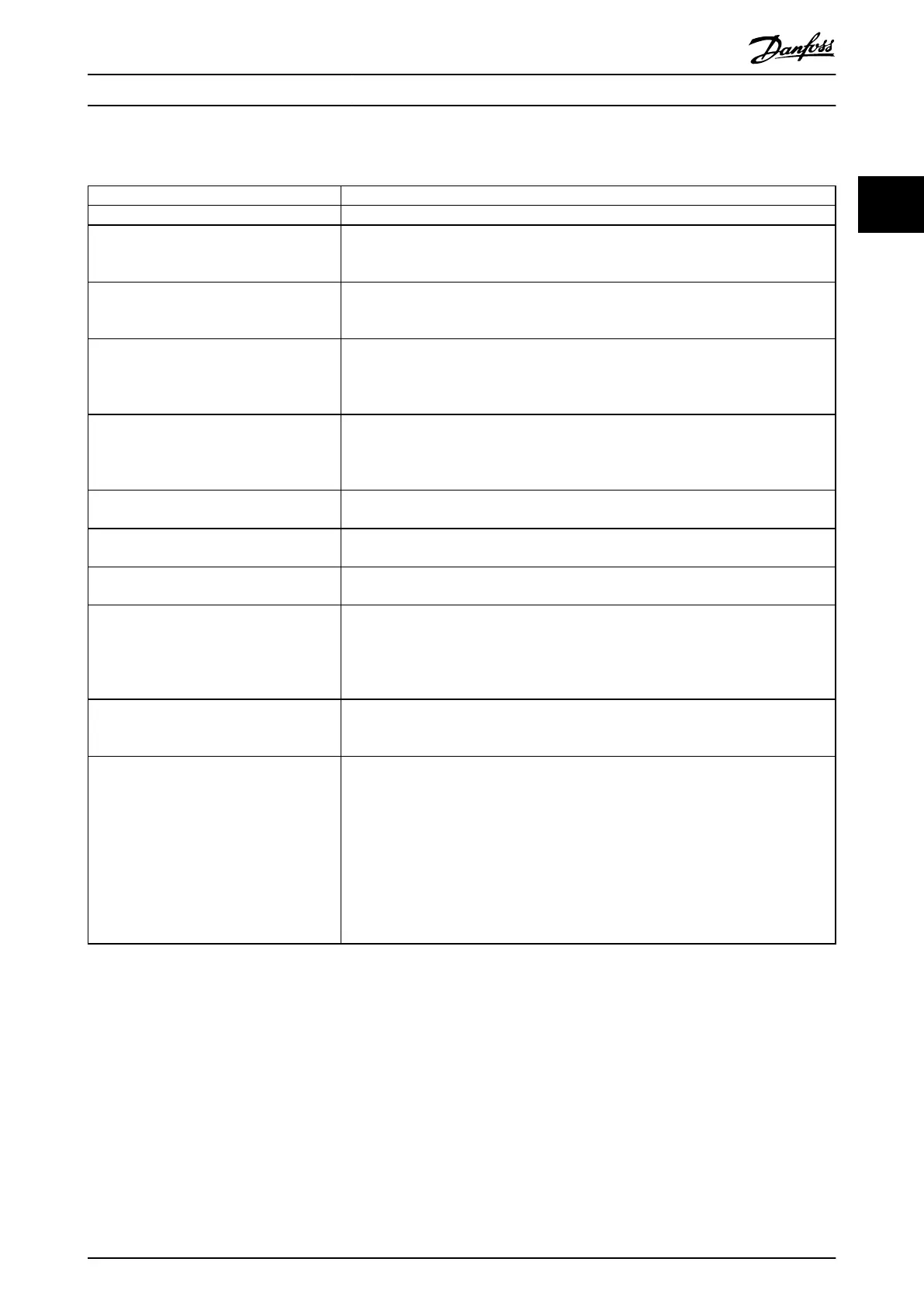

2.5.3 Process Control Relevant Parameters

Parameter Description of function

Parameter 7-20 Process CL Feedback 1 Resource Select from which source (analog or pulse input) the process PID gets its feedback.

Parameter 7-22 Process CL Feedback 2 Resource Optional: Determine if (and from where) the process PID gets an additional feedback

signal. If an additional feedback source is selected, the 2 feedback signals are added

before being used in the process PID control.

Parameter 7-30 Process PID Normal/ Inverse

Control

Under [0] Normal operation, the process control responds with an increase of the motor

speed if the feedback is lower than the reference. Under [1] Inverse operation, the process

control responds with a decreasing motor speed instead.

Parameter 7-31 Process PID Anti Windup The anti-windup function ensures that when either a frequency limit or a torque limit is

reached, the integrator is set to a gain that corresponds to the actual frequency. This

avoids integrating on an error that cannot be compensated for by a speed change. Press

[0] O to disable this function.

Parameter 7-32 Process PID Start Speed In some applications, reaching the required speed/setpoint can take a long time. In such

applications, it may be an advantage to set a xed motor speed from the frequency

converter before the process control is activated. Set a xed motor speed by setting a

process PID start value (speed) in parameter 7-32 Process PID Start Speed.

Parameter 7-33 Process PID Proportional Gain The higher the value, the quicker the control. However, too large a value may lead to

oscillations.

Parameter 7-34 Process PID Integral Time Eliminates steady state speed error. A lower value means a quicker reaction. However, too

small a value may lead to oscillations.

Parameter 7-35 Process PID Dierentiation Time Provides a gain proportional to the rate of feedback change. A setting of 0 disables the

dierentiator.

Parameter 7-36 Process PID Di. Gain Limit If there are quick changes in reference or feedback in a given application (which means

that the error changes swiftly), the dierentiator may soon become too dominant. This is

because it reacts to changes in the error. The quicker the error changes, the stronger the

dierentiator gain is. The dierentiator gain can thus be limited to allow setting of the

reasonable dierentiation time for slow changes.

Parameter 7-38 Process PID Feed Forward

Factor

In applications where there is a good (and approximately linear) correlation between the

process reference and the motor speed necessary for obtaining that reference, use the

feed forward factor to achieve better dynamic performance of the process PID control.

•

Parameter 5-54 Pulse Filter Time Constant

#29 (Pulse term. 29)

•

Parameter 5-59 Pulse Filter Time Constant

#33 (Pulse term. 33)

•

Parameter 6-16 Terminal 53 Filter Time

Constant (Analog term 53)

•

Parameter 6-26 Terminal 54 Filter Time

Constant (Analog term. 54)

If there are oscillations of the current/voltage feedback signal, use a low-pass lter to

dampen these oscillations. The pulse lter time constant represents the speed limit of the

ripples occurring on the feedback signal.

Example: If the low-pass lter has been set to 0.1 s, the limit speed is 10 RAD/s (the

reciprocal of 0.1 s), corresponding to (10/(2 x π))=1.6 Hz. This means that the lter

dampens all currents/voltages that vary by more than 1.6 oscillations per second. The

control is only carried out on a feedback signal that varies by a frequency (speed) of less

than 1.6 Hz.

The low-pass lter improves steady state performance, but selecting a too long lter time

deteriorates the dynamic performance of the process PID control.

Table 2.9 Process Control Parameters

Product Overview Design Guide

MG07B102 Danfoss A/S © 03/2016 All rights reserved. 31

2 2

Loading...

Loading...