48 Part No. 057-009 5110 Operating Manual Issue 3.3 3/1/2006

18.7 FRONT PANEL CONFIGURATION (ORIGINAL 5110)

In April 2005, the 5110 controller was updated to include PC configuration. At this time, a few minor

changes to the front panel configuration were also made.

This section details the configuration editor of the “Original” 5110 module. To identify the “original” and

“new” controllers, See the section entitled

Identification of “original” 5110 and “new” 5110 from V2

onwards

elsewhere in this manual.

NOTE:- PC Configuration is not possible on the “original” 5110 controller. All options must

be edited using the Front Panel Configuration Editor.

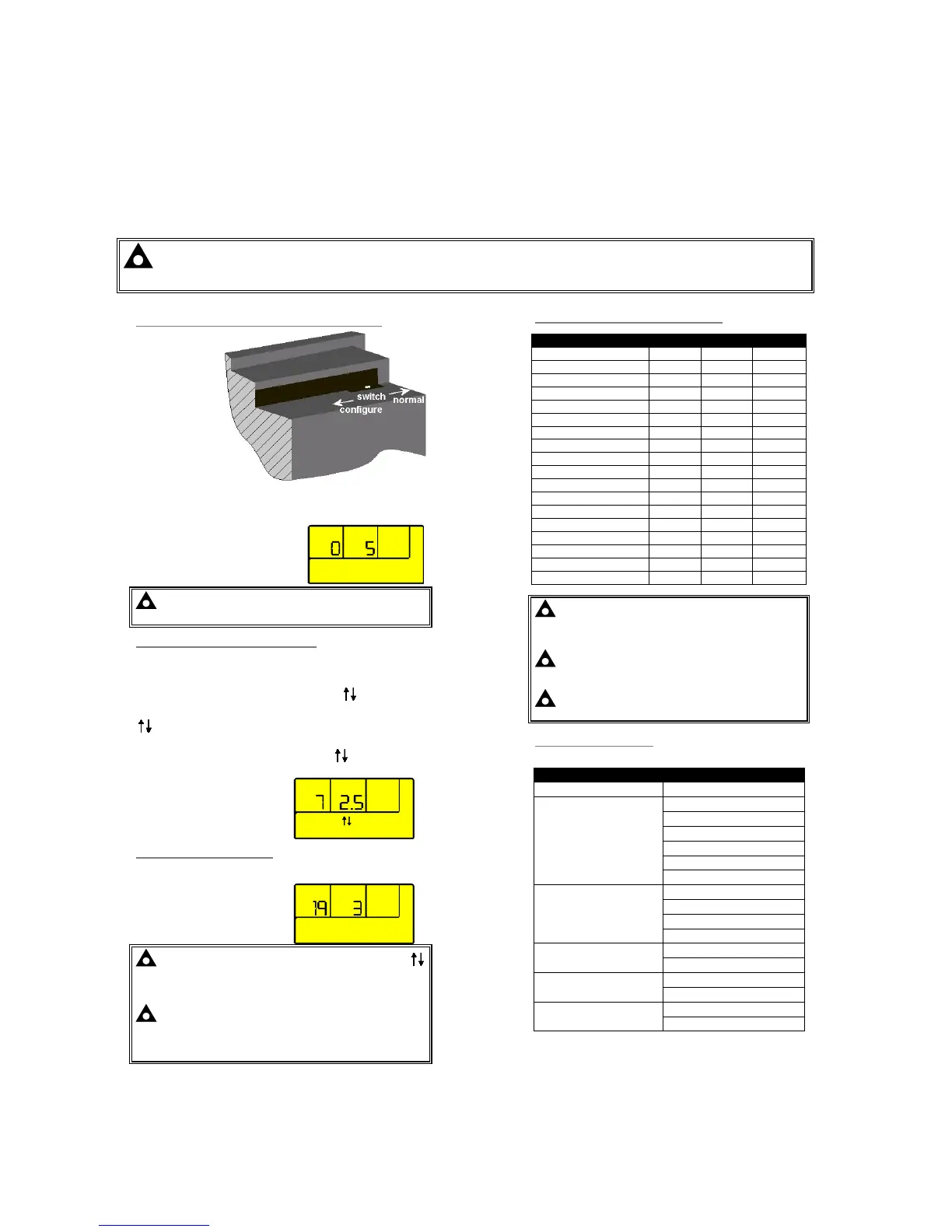

TIMERS & ANALOGUE SETTINGS

Parameter Type

Default

Max

0 - Start delay Timer 5s 60s

1 - Preheat Timer 0s 60s

2 - Crank attempt Timer 10s 60s

3 - Crank rest Timer 10s 60s

4 - Safety delay Timer 8s 60s

5 - Warming up Timer 0s 60s

6 - Return delay Timer 30s 60m

7 - Cooling run Timer 60s 60m

8 - E.T.S. solenoid hold Timer 0s 60s

9 - Low Oil Pressure Trip 15PSI 150PSI

10 - High Temperature Trip 95°C 150°C

11 - Under Speed Trip 1250RPM 3600RPM

12 - Over Speed Trip 1750RPM 5000RPM

13 – Underfrequency Trip 40Hz 60Hz

14 - Overfrequency Trip 57Hz 72Hz

15 - Charge Alt Failure Warning 8V DC 25V DC

16 - Flywheel teeth Value 0 300

17 - CT Primary Value 500A 6000A

NOTE:- Setting a timer to zero (0) will disable it. Timer settings

increment from 0 to 60s in steps of 1s and from 1 minute to the

maximum value in steps of 30 seconds (0.5 minutes) (where

applicable)

NOTE:- Setting Flywheel teeth to zero (0) will disable magnetic

pickup speed sensing. In this instance, engine speed is derived from

the alternator output frequency.

NOTE:- CT values increment from 10-100 in steps of 10A, and

from 100 to 6000A in steps of 50A. CT secondary must be 5A.

LIST ITEM SETTINGS

Factory default settings are in bold italicised text.

Parameter Selections

18 - Alternator poles 0,2,4,6,8

19 - Oil Pressure 0 - Switch close to activate

transducer 1 - Switch open to activate

2 - VDO 0-5bar

3 - VDO 0-10bar

4 - Datcon 0-5bar

5 - Datcon 0-10bar

20 - Coolant temp 0 - Switch close to activate

transducer 1 - Switch open to activate

2 - VDO 0-120

°

C

3 - Datcon High

21 - Fast loading 0 - No

enabled 1 - Yes

22 - AC system 1 - 1 phase 2 wire

3 - 3 phases 4 wires

23 - Oil pressure 0 - Bar/PSI

display units 1 - kPa

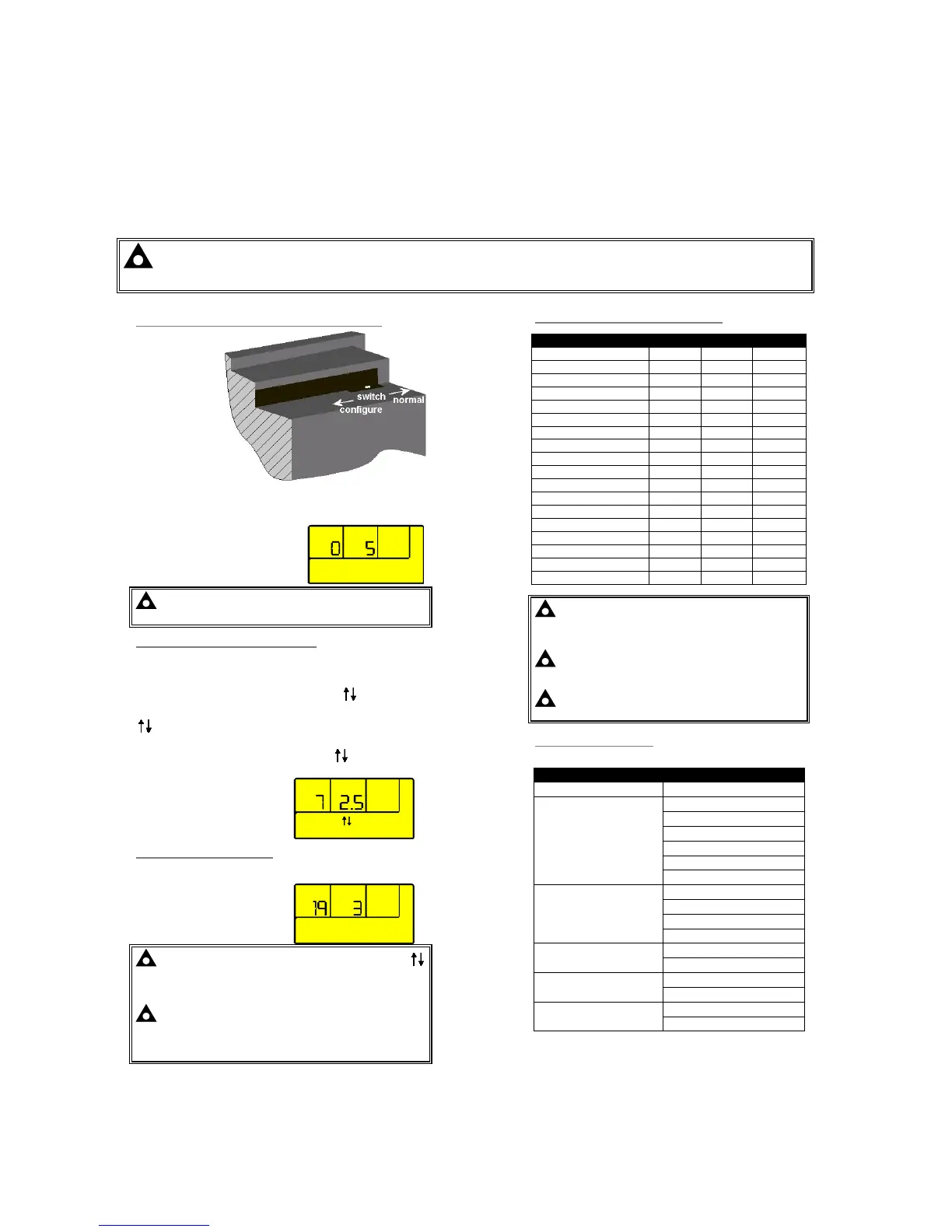

ACCESSING THE CONFIGURATION EDITOR

Operate the

Configuration

mode switch into

the “configure”

position. (This

recessed switch is

located on the

rear of the module

in the top right

corner when

viewing the

module from the

back.)

The LED indicator beside the AUTO 9 button will flash to show

that the module is now in configuration mode. While in

configuration mode, all normal operation is suspended.

The first configurable parameter is

displayed. In this example, the

Start delay timer (parameter 0). Is

currently set to 5s.

NOTE:- The module must be in STOP mode with the

engine at rest in order to enter the configuration editor.

EDITING AN ANALOGUE VALUE

Enter the configuration editor as described above.

Press the + / – buttons to select the parameter you wish to

change using the following lists as a reference.

Press the 9 button to enter adjust mode.The

icons in the

module display will flash. Pressing the + or – buttons while the

icons are flashing will change the selected parameter to the

desired value.

Press the 9 button to ‘save’ the value. The

icons will stop

flashing to confirm that it has been saved.

The parameter being displayed in

this example is the cooling timer

(parameter 7). It’s current value is

2.5mins (2mins 30secs).

EDITING A ‘LIST’ VALUE

Some configuration parameters have a list of options to select

from. These include input and output settings.

This example shows the setting

for oil pressure transducer

(parameter 19). It’s current setting

is 3 (‘VDO 0-10bar’ from the list

shown opposite).

NOTE:- When in adjust mode (indicated by the flashing

icons in the module display), pressing the O (stop mode) button

will cancel any changes made to the current parameter,

reverting to the last ‘saved’ value. This also exits adjust mode.

NOTE:- To exit the front panel configuration editor at any

time, move the Configuration mode switch back into the

“normal” position. Ensure you save any changes you have

made by pressing the 9 button first if necessary.

Loading...

Loading...