8.5.9 Slipping clutch

8.5.9.1 Checking the slipping clutch

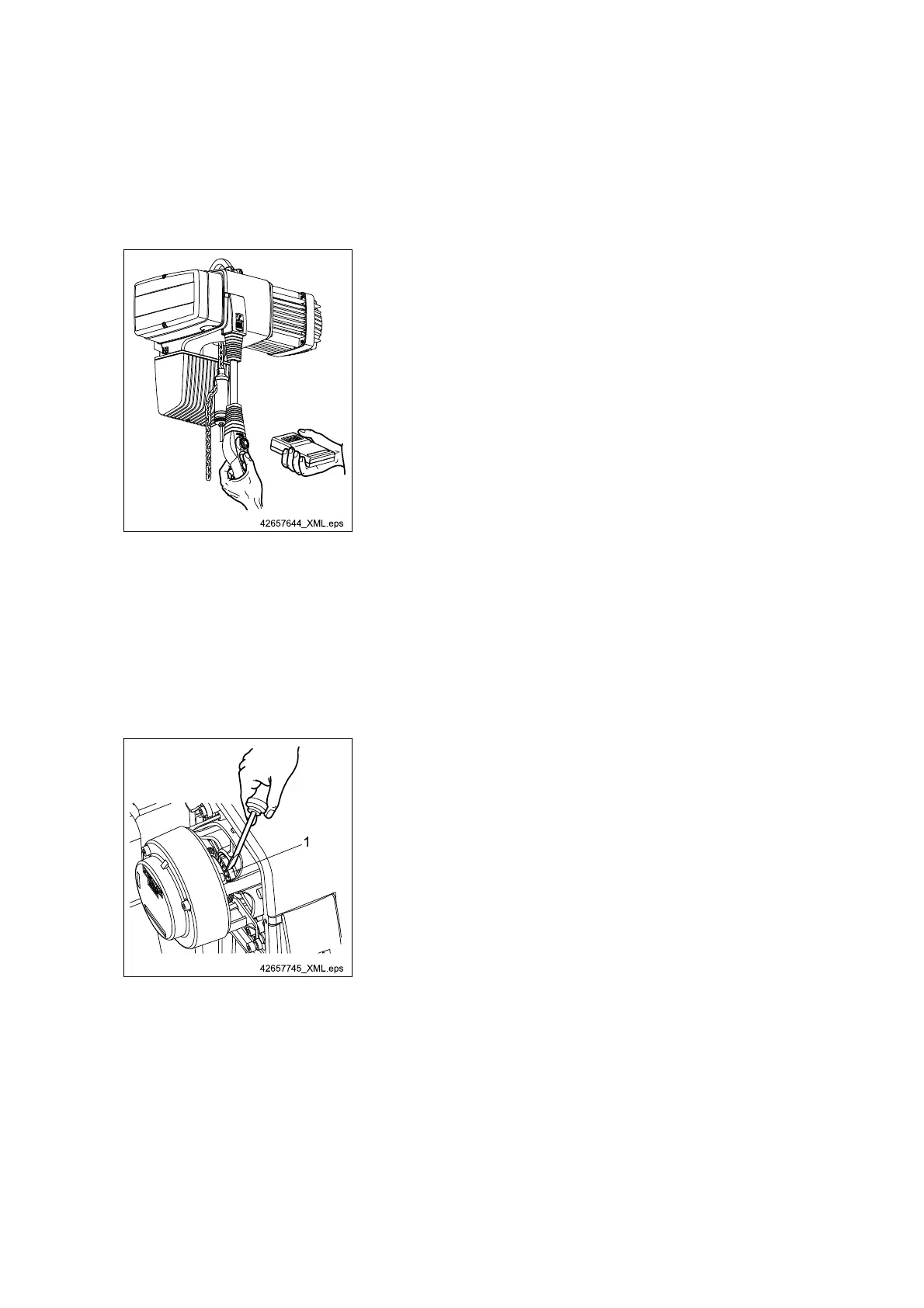

Fig. 66

The slipping clutch performs the function of an emergency limit stop de‐

vice and protects the chain hoist against overloads.

The slipping clutch is initially set in the factory. Under normal operating

conditions, the slipping clutch does not need to be adjusted. In the course

of the annual inspection, the slipping clutch must be checked.

Adjustment of the slipping clutch may only be carried out by authorized

specialists. An increase of the tripping torque which exceeds the factory

setting is not permitted.

Check the slipping clutch function as follows:

● In order to remove the limit stop, the chain collector box must be dis‐

connected, ⇒ "Dismantling the chain collector box", Page 77. Remove

the limit stop ⇒ Fig. 55, Page 87 from the chain fall which is not under

load and fit it above the hook assembly. Run the limit stop against the

guide plate at creep speed. The operating limit switches, if existing,

must not be actuated while this is being done.

If the slipping clutch is functioning correctly, the following will be ob‐

served:

● the hoist motor fan is still turning while there is no lifting motion;

● The 7-segment display shows the SLIP LIFTING V1 warning,

⇒ "Warning messages", Page 104.

When the slipping clutch function has been checked, the limit stop must

be fitted again to the section of chain which is not under load.

8.5.9.2 Adjusting the slipping clutch

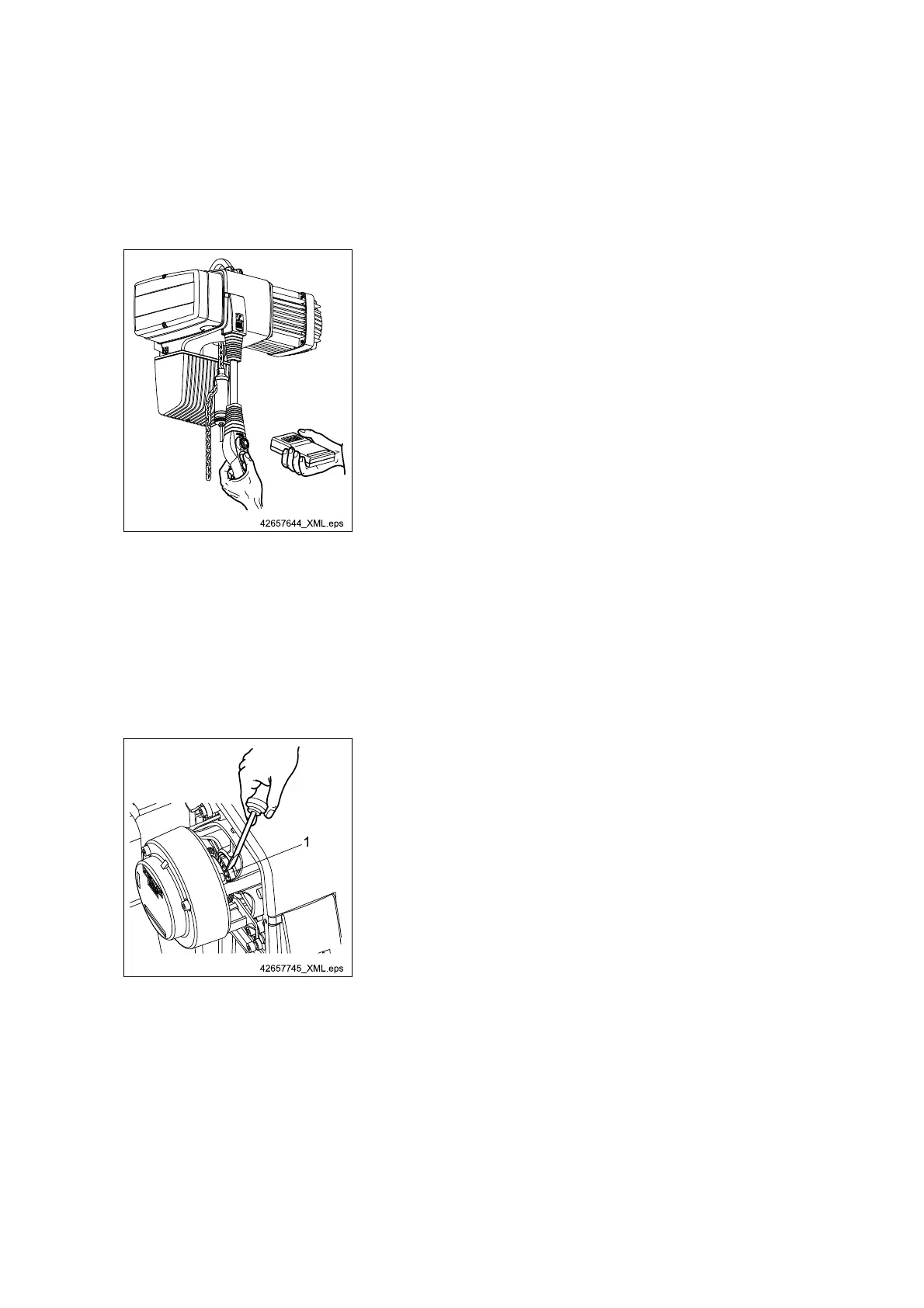

Fig. 67

During the final inspection in the factory, the slipping clutch is set to the

load capacity of the chain hoist. An increase of the tripping torque which

exceeds the factory setting is not permitted, see also ⇒ "Suspending the

chain hoist", Page 43.

For DC-Com chain hoists ≥ 1000 kg the setting complies with the re‐

quirements of EN 14492-2 for slipping clutches as overload protection.

Overload protections are prescribed for load capacities ≥ 1000 kg.

During the acceptance test of the hoist or crane installation, a load of

110% of the load capacity must be lifted within the dynamic overload test

(without any change in the setting of the slipping clutch). A load > 160%

must not be lifted, (EN 14492-2 "Directly acting overload protections").

The slipping clutch is protected against overload by slip monitoring so that

re-setting is only necessary during the general overhaul. If owing to the

operating conditions or malfunctions, the setting needs to be checked, the

friction force checking device, ⇒ part no. 836 708 44, must be used. In‐

spection and adjustment may only be carried out by an experienced

technician in compliance with the instructions for the friction force check‐

ing device ⇒ Tab. 3, Page 7.

96

21480244/181209

Loading...

Loading...