8.5.5.6 Available hoist chains

The original Demag chain is a round section steel chain tested to EN 818-7 which is subject to the directives for

round section steel chains in hoisting operation of the Main Association of Industrial Employers' Mutual Insurance

Societies, Central Department for Accident Prevention and to the test criteria for round section steel chains in hoisting

operation and to the inspection regulations according to DIN 685 part 5 Nov. 1981 as well as BGV D8 (VBG 8) and

BGV D6 (VBG 9).

CAUTION

Pay attention to reduced capacity.

Deviating from the standard operating conditions for which RDC chains are used, the special chains listed in the

following are available for special ambient conditions.

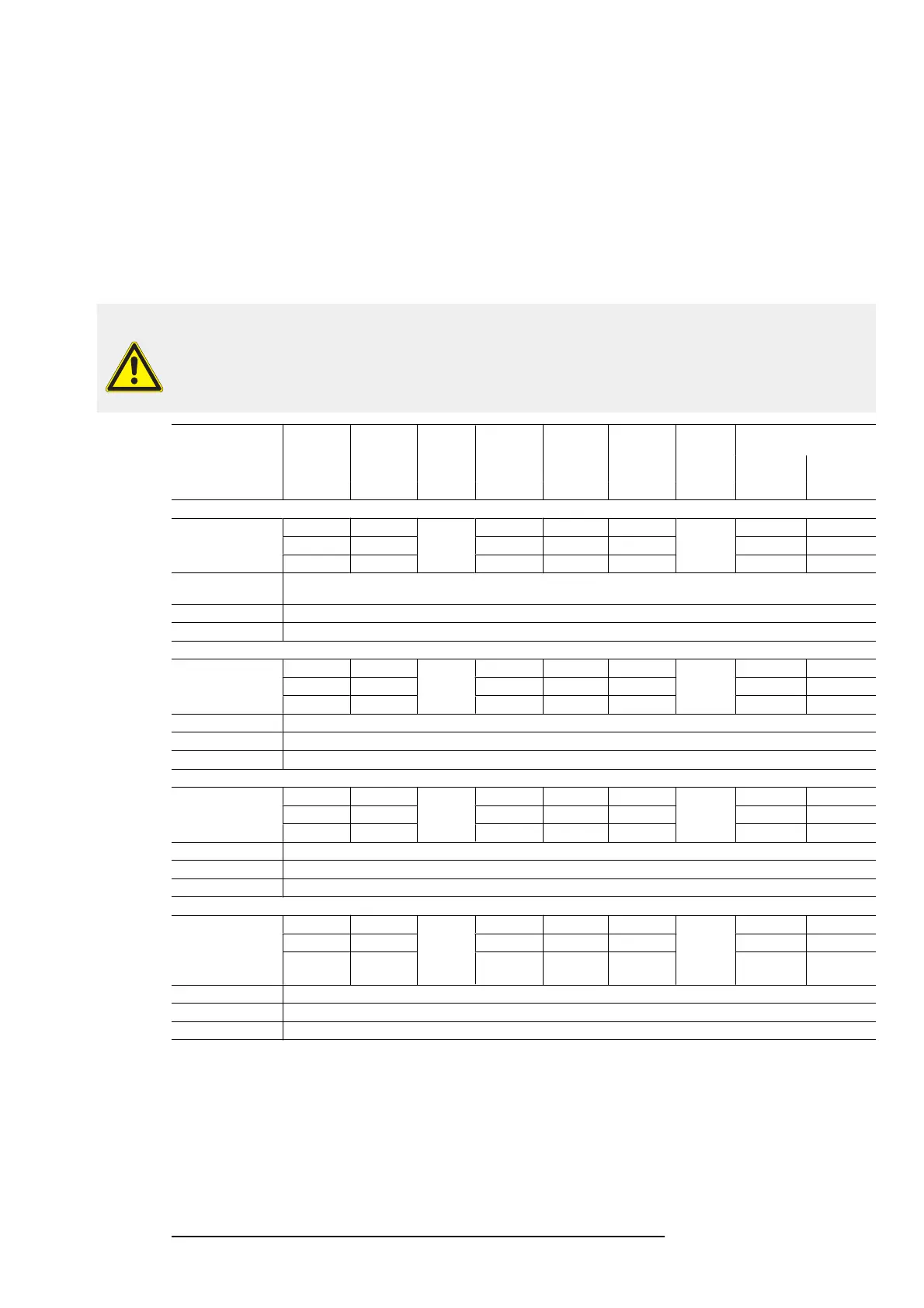

Chain hoist

size

Dimension Stamp,

chain

quality

Weight per

meter

Production

test force

Minimum

breaking

force

Minimum

breaking

elonga‐

tion

Max. load capacity for reev‐

ing

1/1 2/1

[mm]

[kg] [kN] [kN] [%] [kg] [kg]

Demag RDC standard chain

DC 1 / 2 4.2 x 12.2

DAT /

RDC

0,38 13,8 22

10

250 -

DC 5 5.3 x 15.2 0,62 22 35 500 -

DC 10 7,4 x 21,2 1,20 43 70 1250 2500

Properties

High strength, ageing-resistant material with a high degree of surface hardening, galvanised with additional surface treat‐

ment, blue chromated, colour: silver

Material Ni-Mo special chain steel acc. to EN 818-7, part 5.3.1

Lubrication Grease GP00H-30REN.SO-GFB

Demag Corrud special chain

Application e.g.

galvanizing, electro‐

plating facilities

DC 1 / 2 4.2 x 12.2

DAT /

RDC

0,38 13,8 22

10

250 -

DC 5 5.3 x 15.2 0,62 22 35 500 -

DC 10 7,4 x 21,2 1,20 43 70 1250 2500

Properties Ageing-resistant, corrosion-free, micro-layer corrosion protection “Corrud DS” coated black, colour black, Stabylan 2001

Material Ni-Mo special chain steel acc. to EN 818-7, part 5.3.1

Lubrication Acid-resistant chain grease

Demag HS7 special chain

Application e.g.

foundry, dust, emery,

blasting

DC 1 / 2 4.2 x 12.2

RSX / DS

0,38 12,5 19,3

5

160 -

DC 5 5.3 x 15.2 0,62 19,8 30,8 400 -

DC 10 7,4 x 21,2 1,20 38,7 60 800 1600

Properties Ageing-resistant, blue chromated, with deeper hardening surface

Material Ni-Mo special chain steel acc. to EN 818-7, part 5.3.1

Lubrication Dry or with dry lubricant, e.g. Klüber UNIMOLY C220

Demag RS6 special chain

Application e.g.

foodstuffs sector

DC 1 / 2 4.2 x 12.2

RSA / S

0,38 10 16

15

125 - 160 -

DC 5 5.3 x 15.2 0,62 16 25 200 - 250 -

DC 10 7,4 x 21,2 1,20 32 50

400 - 500

28)

800 - 1000

29)

Properties Non-rusting chain, not hardened, bright

Material Stainless steel AISI 316 (V4A) 1,4401

Lubrication Edible lubricant, e.g. Paraliq chain spray

Tab. 55

28)

For max. 10 cycles per day = 500 kg For max. 25-50 cycles per day = 400 kg

29)

For max. 5 cycles per day = 1000 kg; for max. 12-25 cycles per day = 800 kg

21480244/181209

83

Loading...

Loading...