8.3.4 General overhaul GO

The chain hoists are designed for a period of use of at least 10 years until the first general overhaul is carried out.

This is based on the condition that the specified group of mechanisms is not exceeded by the actual duration of

service. When the actual duration of service has reached the theoretical duration of service valid for the group of

mechanisms, further operation of the chain hoist is only permissible after a general overhaul.

The theoretical duration of service D (hours at full load h) depends on the group of mechanisms classification of the

chain hoist. The actual duration of service is to be determined annually in accordance with FEM 9.755. During the

annual inspection by our after-sales service, you may have the actual service life determined.

Upon expiration of 90% of the theoretical duration of service – if the chain hoists are correctly classified after 8 to 10

years – the owner must arrange for a general overhaul GO to be carried out. A general overhaul must be carried out

no later than when the end of the theoretical duration of service is reached.

During the general overhaul the following parts must be replaced in addition to the checks and work specified in the

inspection and maintenance schedule:

● Gearbox housing with joined gearing parts,

● Gear oil and gearbox cover with seal,

● Connecting elements,

● Shaft sealing rings, bearings, plugs,

● Brake.

The small parts (screws, washers, etc.) to be replaced during maintenance and assembly work are not listed sep‐

arately. The general overhaul carried out by the manufacturer or an authorized specialist company fulfills the

condition for continued operation of the chain hoist.

Thus the relevant accident prevention regulations and the BGV D8 (VBG 8) are complied with.

Further utilization is approved when an expert engineer has entered the conditions for further utilization into the test

and inspection booklet. Completion of the general overhaul must be confirmed in the test and inspection booklet and

a further period of utilization in accordance with FEM 9.755 must be entered.

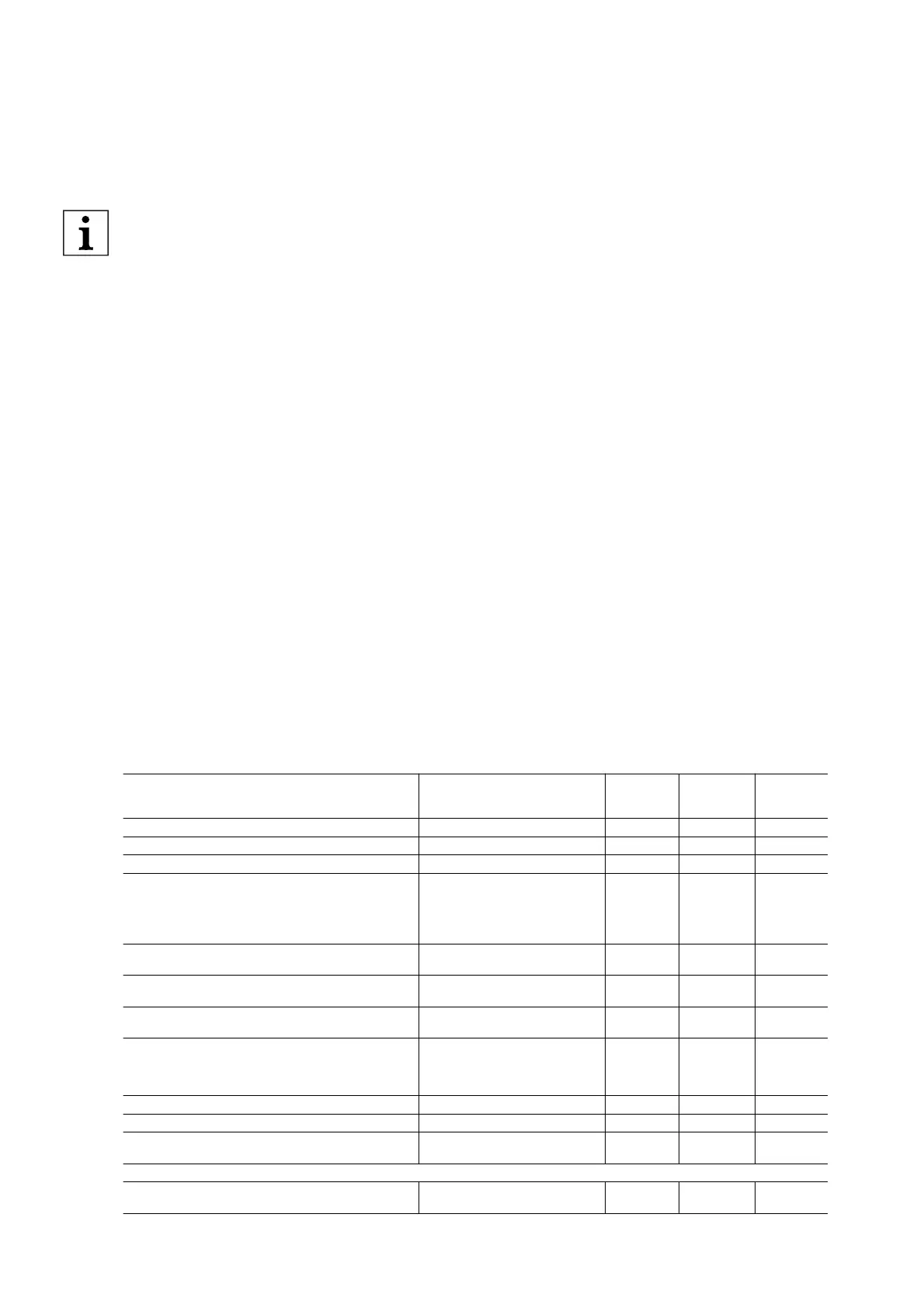

8.4 Inspection and maintenance schedule

Action Section Before first

putting into

operation

Before start‐

ing work

In the course

of annual in‐

spection

Check continuity of the PE conductor connection - X

Check emergency stop device - X X

Check direction of movement ⇒ „Line connection“, Page 48 X

Check 7-segment display ⇒ „7-segment display for operating

status and error display“, Page 31,

⇒ „Software version, operating

hours, number of cycles, operating

statuses“, Page 31

X X

Check chain lubrication (under arduous conditions, the chain

must be lubricated more frequently)

⇒ „Available hoist chains“,

Page 83

X X X

Check function of operating limit switch for lifting ⇒ „Checking the operating limit

switches“, Page 77

X X X

Check function of operating limit switch for lowering ⇒ „Checking the operating limit

switches“, Page 77

X X

Check swich-off buffer / switch-off spring / operating limit

switch actuator

⇒ „Checking the swich-off buffer /

switch-off spring“, Page 91

⇒ „Checking the operating limit

switch actuator“, Page 78

X X X

Check control cable and control pendant housing for damage - X X X

Check operation of the brake - X X X

Check hook and hook safety catch ⇒ „Checking the load hook“,

Page 88

X X X

Read the switching cycles C ⇒ „Service life of the contactor“,

Page 70

X

74

21480244/181209

Loading...

Loading...