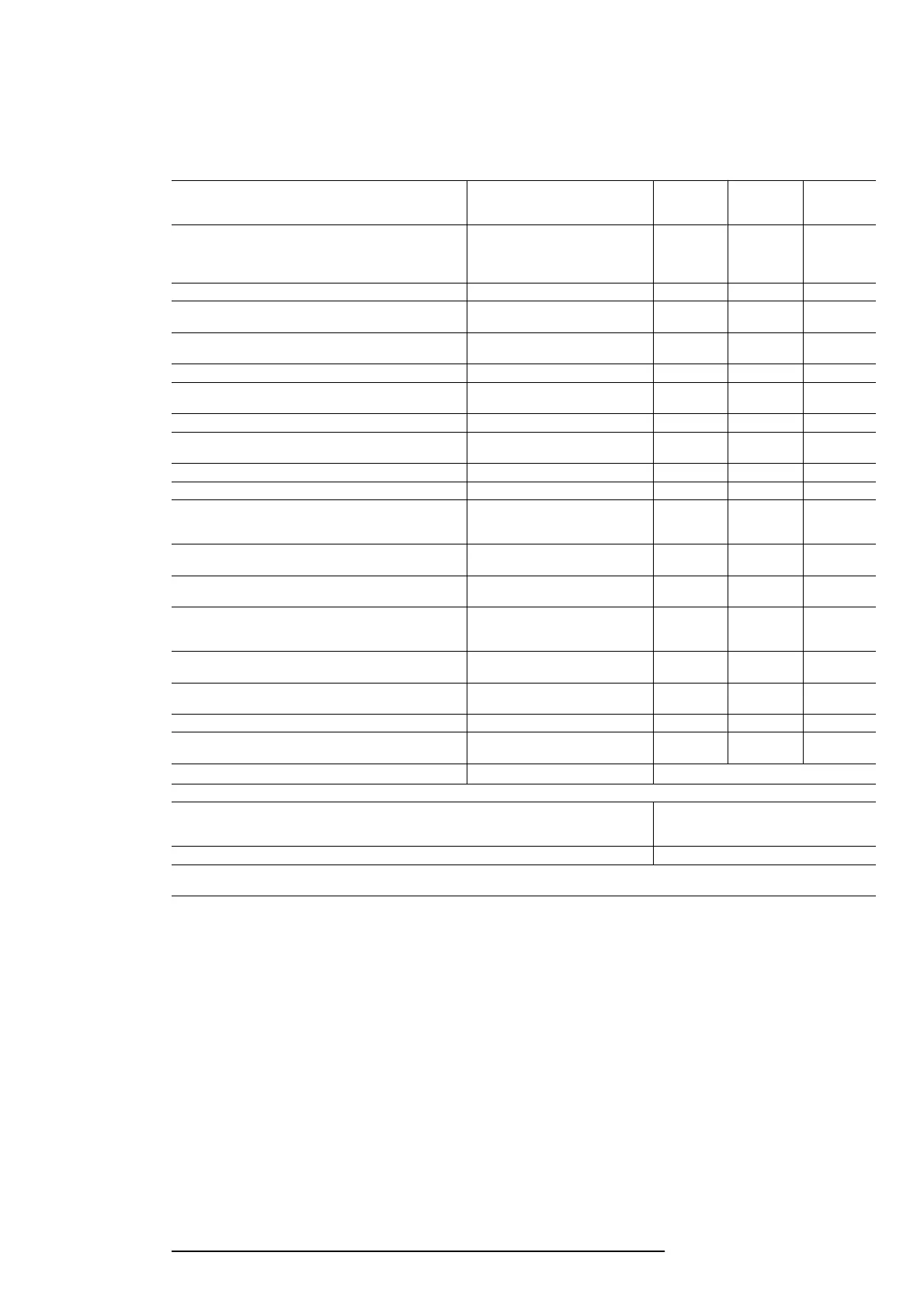

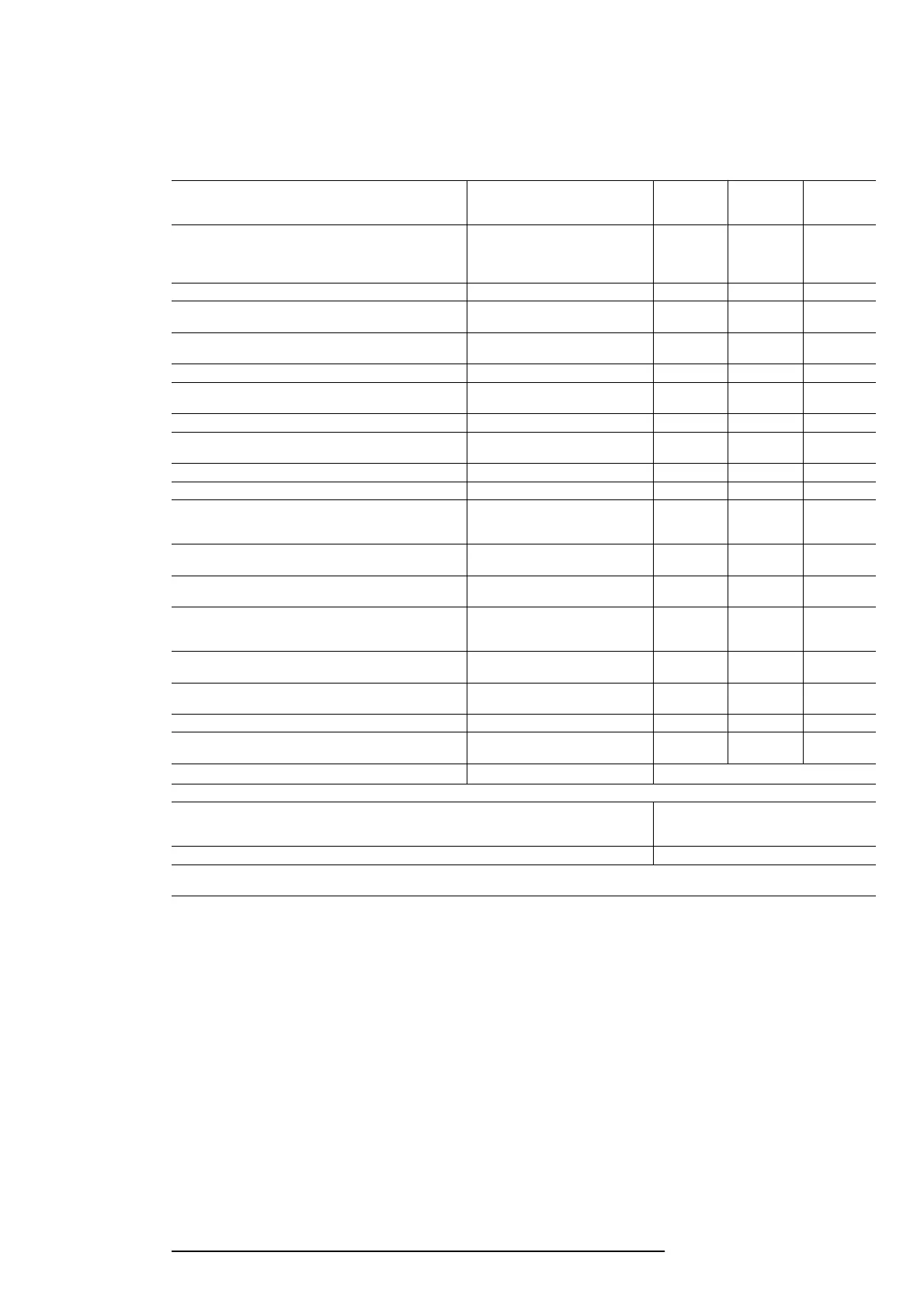

Action Section Before first

putting into

operation

Before start‐

ing work

In the course

of annual in‐

spection

Read operating hours for determining the remaining duration

of service

⇒ „7-segment display for operating

status and error display“, Page 31

⇒ „Measures for achieving safe

working periods S.W.P.“, Page 71

X

Check electrical switchgear and wiring - X

Check operation of the slipping clutch ⇒ „Checking the slipping clutch“,

Page 96

X

Check setting of the slipping clutch ⇒ „Adjusting the slipping clutch“,

Page 96

X

Check brake wear ⇒ „Brake“, Page 94 X

Check suspension, suspension bracket and securing ele‐

ments (clip, etc.)

⇒ „Suspension“, Page 76

X

Check fastening screws on hook assembly / bottom block - X

Check hooks for cracks, deformation and wear ⇒ „Checking the load hook“,

Page 88

X

Check hook safety catch for deformation - X

Check hook bearing for wear - X

Check rubber lip seal in the bottom block ⇒ „Replacing the (standard) bottom

block with internal switch-off springs,

reeving 2/1“, Page 90

X

Check sprocket of chain guide, chain sprocket of bottom

block, chain guide, guide plate

⇒ „Chain drive“, Page 79

X

Check that the chain and chain collector box are properly

secured

-

X

Check the chain for deformation, damage, cracks, pitting,

reduction in the thickness of the links or increase in pitch due

to wear, elongation caused by deformation

⇒ „Checking the hoist chain“,

Page 79

X

Check securing elements (clips, bolts, etc.) for tight fit and

corrosion

-

X

Check and apply or supplement corrosion protection, as re‐

quired

-

X

Check electrical enclosure and gearbox for leakage - X

Check trolley, crossbar and status of buffers ⇒ „Checking the swich-off buffer /

switch-off spring“, Page 91

X

Change oil ⇒ „Gearbox / oil change“, Page 97

Every 10 years

27)

General overhaul

The general overhaul should coincide with the annual inspection

On reaching 90% of the theoretical duration

of service ⇒ „Measures for achieving safe

working periods S.W.P.“, Page 71

Fit chain hoist-specific Demag GO set X

The small parts (screws, washers ...) to be replaced during maintenance and assembly work are not listed separately. During the general overhaul,

the checks and work specified in the inspection and maintenance schedule must be carried out.

Tab. 49

27)

For use in accordance with the FEM classification

21480244/181209

75

Loading...

Loading...