4 Technical description

4.1 Drive and brake

A robust pole-changing AC asynchronous motor is used as hoist motor. The brake is arranged on the load side so

that after an eventual tripping of the slipping clutch, the load is safely braked and held. The bake is released elec‐

trically. Pressure springs ensure automatic brake application when the motor current is switched off or in the event

of a power failure. When the slipping clutch is tripped and fault states occur, the motor is automatically switched off,

at the same time the brake is applied.

First the hoist drive decelerates by switching from the fast speed (2-pole winding) to the creep lifitng speed (8-pole

winding). Mechanical braking is performed when the creep lifting speed is almost reached.

When the emergency-stop button is actuated, mechanical braking is immediately performed independent of the lifting

speed.

Electrical or regenerative braking of the motor considerably recudes wear of the mechanical brake.

4.2 Gearbox and slipping clutch

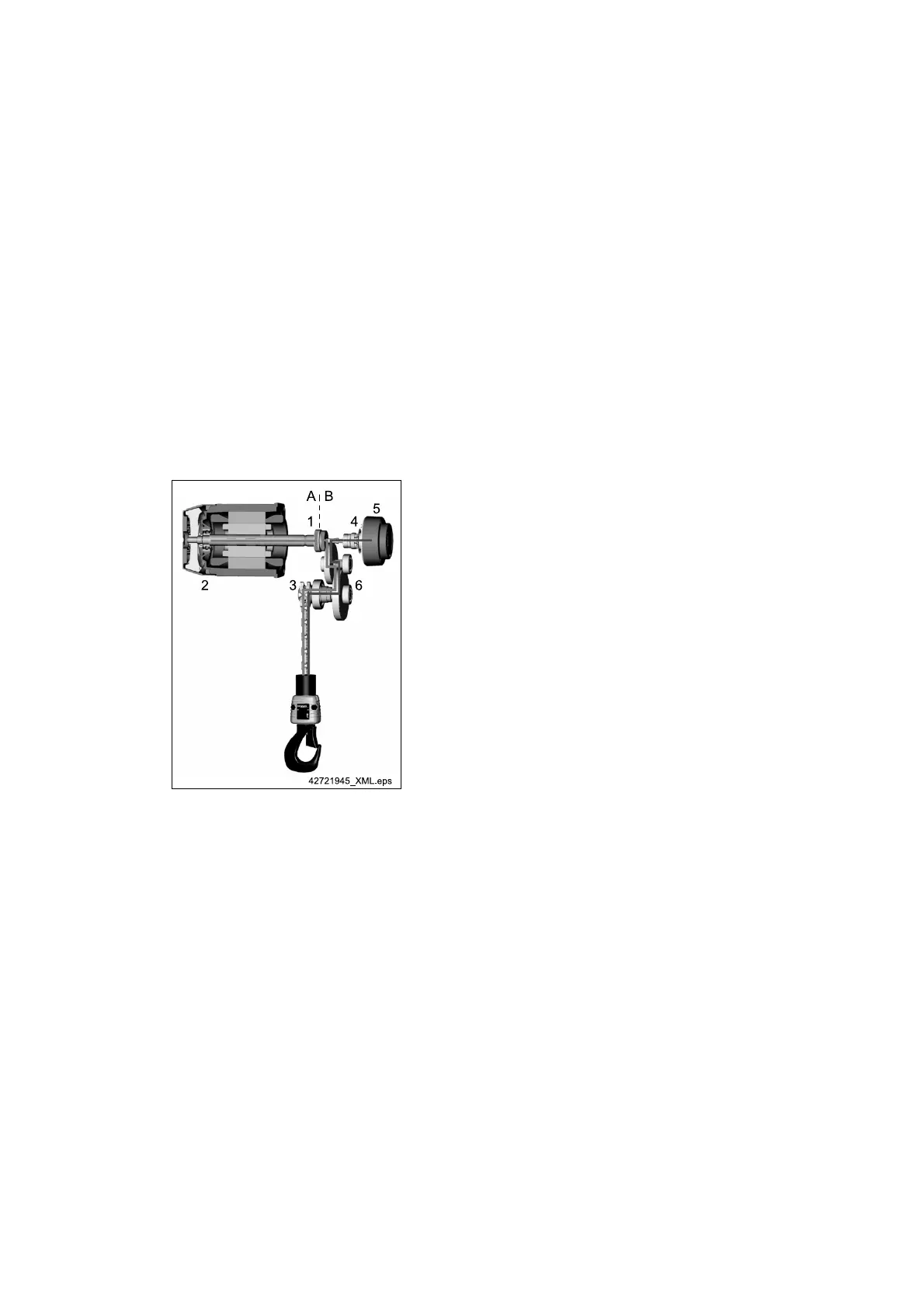

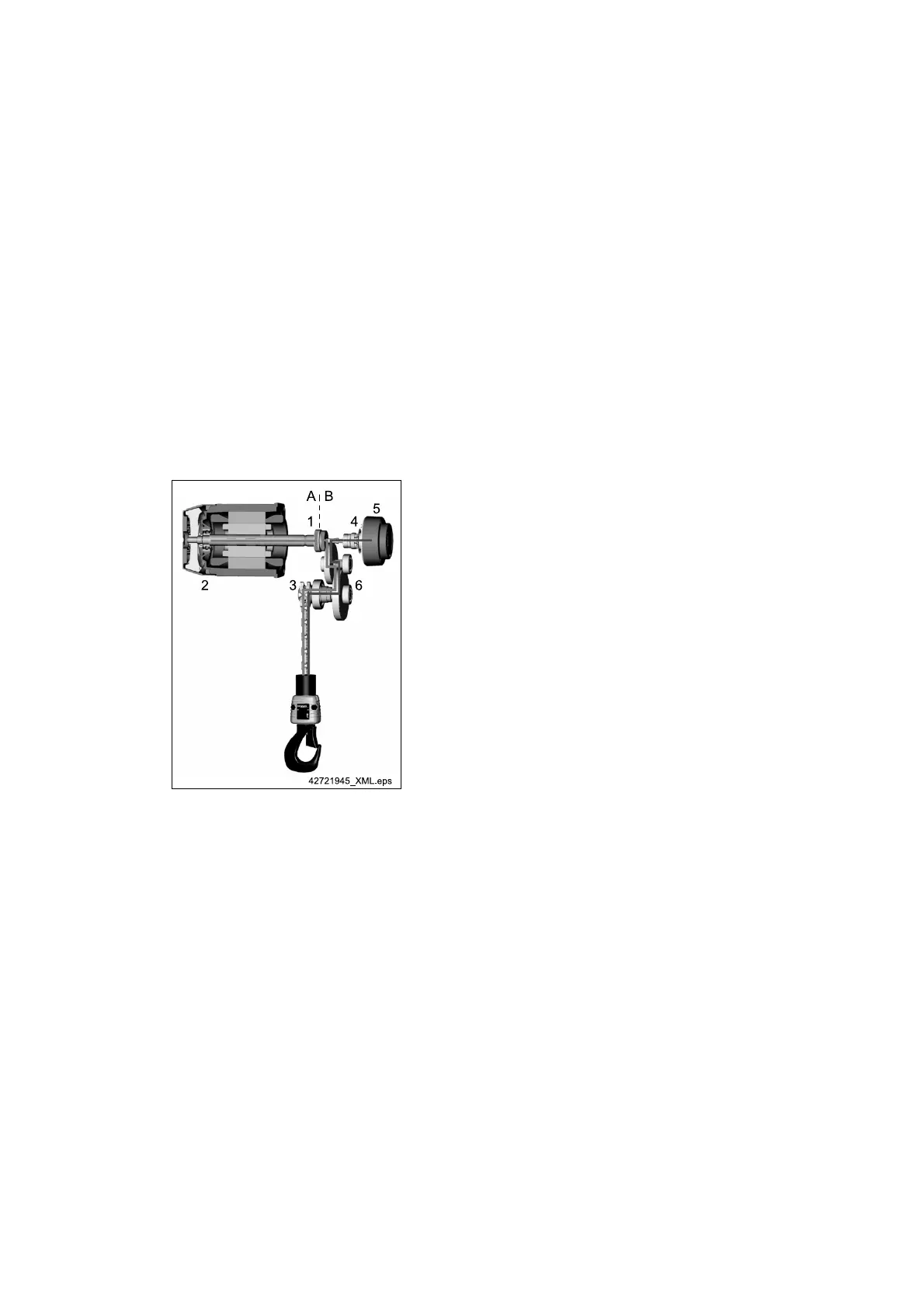

Fig. 7 Transmission of power

ADriving Bbrakes

1 Slipping clutch 4 Speed detection

2 Motor 5 Brake

3 Chain drive 6 Gearboxes

Tab. 20

The slipping clutch is arranged between the motor shaft and the gearbox input shaft. In connection with the end

stops on the chain, it performs the function of the emergency limit stop device for the highest and lowest hook position

and protects the Demag chain hoist against overload. The additional electrical operating limit switches (DC-Com 10

reeving 2/1 as standard, DC-Com 1-10 reeving 1/1 optional)) for the highest and lowest hook position prevent the

slipping clutch from being approached as an emergency limit stop device during normal operation. The slipping

clutch also fulfills the EC directive requirements for a load control device from a load capacity of 1000 kg on.

The brake arranged on the load side prevents load sinking when the unit is at rest. Monitoring the slipping clutch

and automatically switching off the drive in the event of slip increase the service life and protect the slipping clutch

against overload and incorrect use. The gearbox is maintenance-free for up to 10 years.

21480244/181209

29

Loading...

Loading...