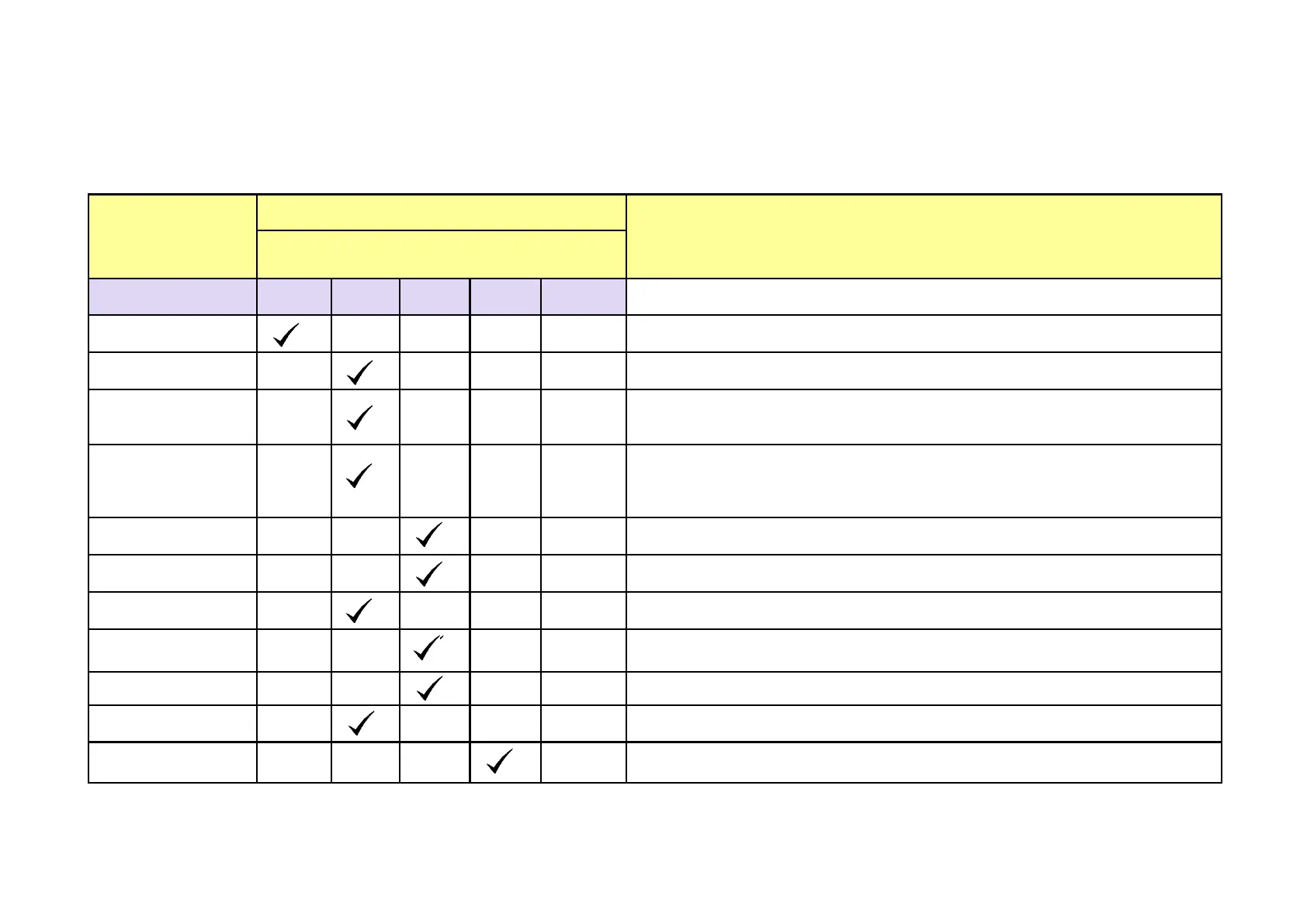

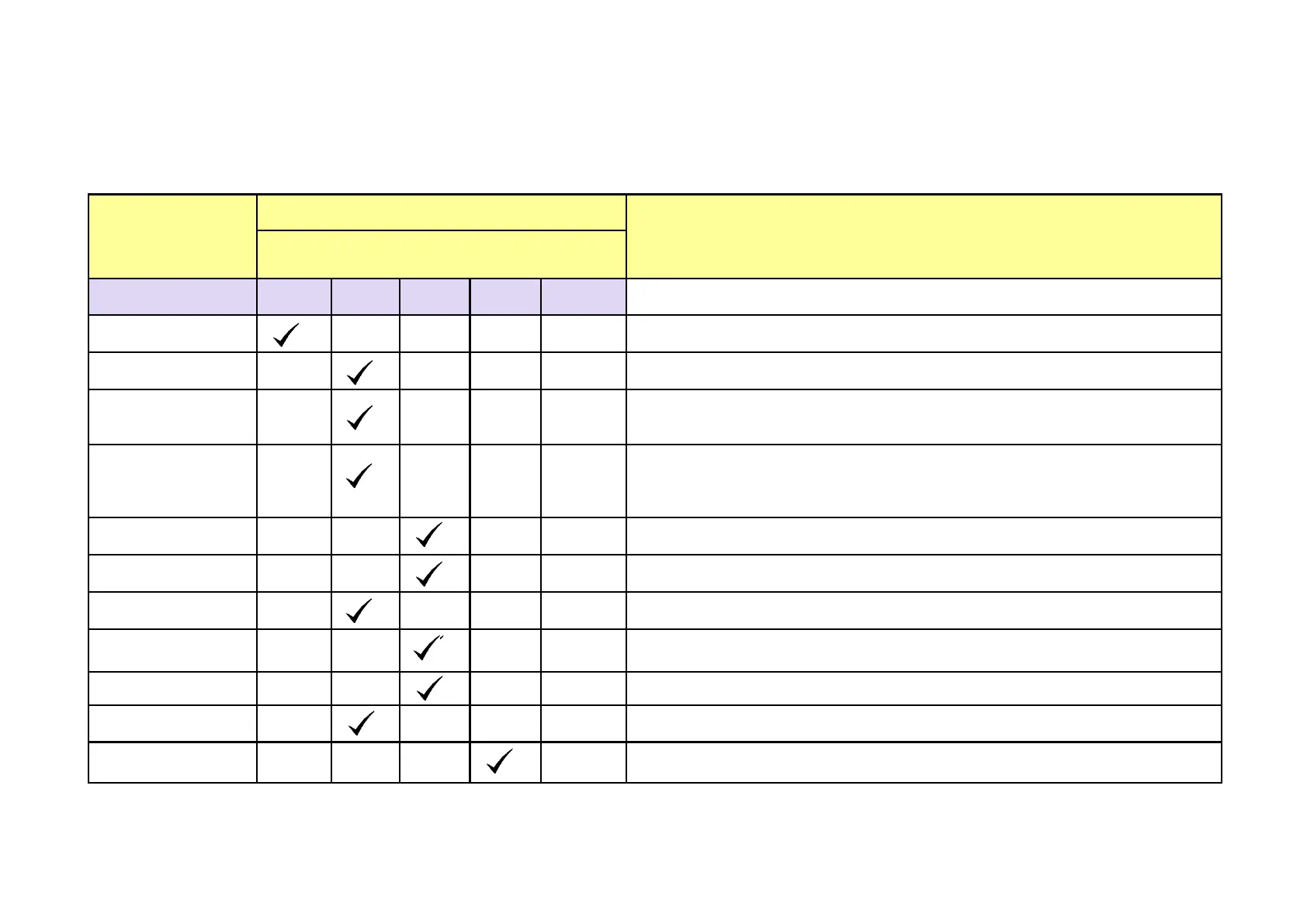

HI, MI, WI-700 service manual - 6 – maintenance schedule

6-5 Issue 9 04/2020

700 SERIES MACHINE ROUTINE MAINTENANCE SCHEDULE

Note: based on a 16-hour day. Daily & yearly checks to be carried out regardless of actual running time.

Weekly, monthly & 3 monthly intervals may be adjusted to suit actual machine running time.

MACHINE AREA /

COMPONENT

FREQUENCY OF TASK

DETAILS OF TASK

3

DAILY WEEKLY MONTHLY MONTHLY YEARLY

LABELLER

THERMAL HEAD Clean thermal head.

(Refer to service manual, routine maintenance section)

THERMAL HEAD Check thermal head print face for wear or damage and any missing dots from print,

replace when defective.

WEAR STRIP &

silicone tube -

Signature labeller

Check condition of wear strip and silicone tube for damage or general wear.

Check the surface is clean and smooth, replace when worn or damaged

PLATEN ROLLER &

BEARINGS (classic /

cassette labeller /

Signature option)

Check condition of platen roller rubber for damage or general wear.

Check smooth rotation of roller; replace end bearings if roller does not turn freely

FREE RUNNING

ROLLERS

Clean all free running rollers.

Check roller shafts are secure on baseplate.

Check free rotation of each roller. Clean or replace any roller / roller shaft not

turning freely.

DRIVE/PINCH

ROLLERS

Clean both rollers

(Refer to service manual, routine maintenance section)

Check adjustment between rollers and free rotation of metal roller (classic labeller).

Check metal roller moves freely under spring tension for Signature labeller

Check for wear of the rubber surface on the drive roller

BLOW BAR Check bar is clean and blow holes are in the correct position

TAKE-UP & DRIVE

BELTS

Check condition and tension of drive and take up belts, replace if teeth on belt are

worn or missing.

Loading...

Loading...