HI, MI, WI-700 service manual - 6 – maintenance schedule

6-8 Issue 9 04/2020

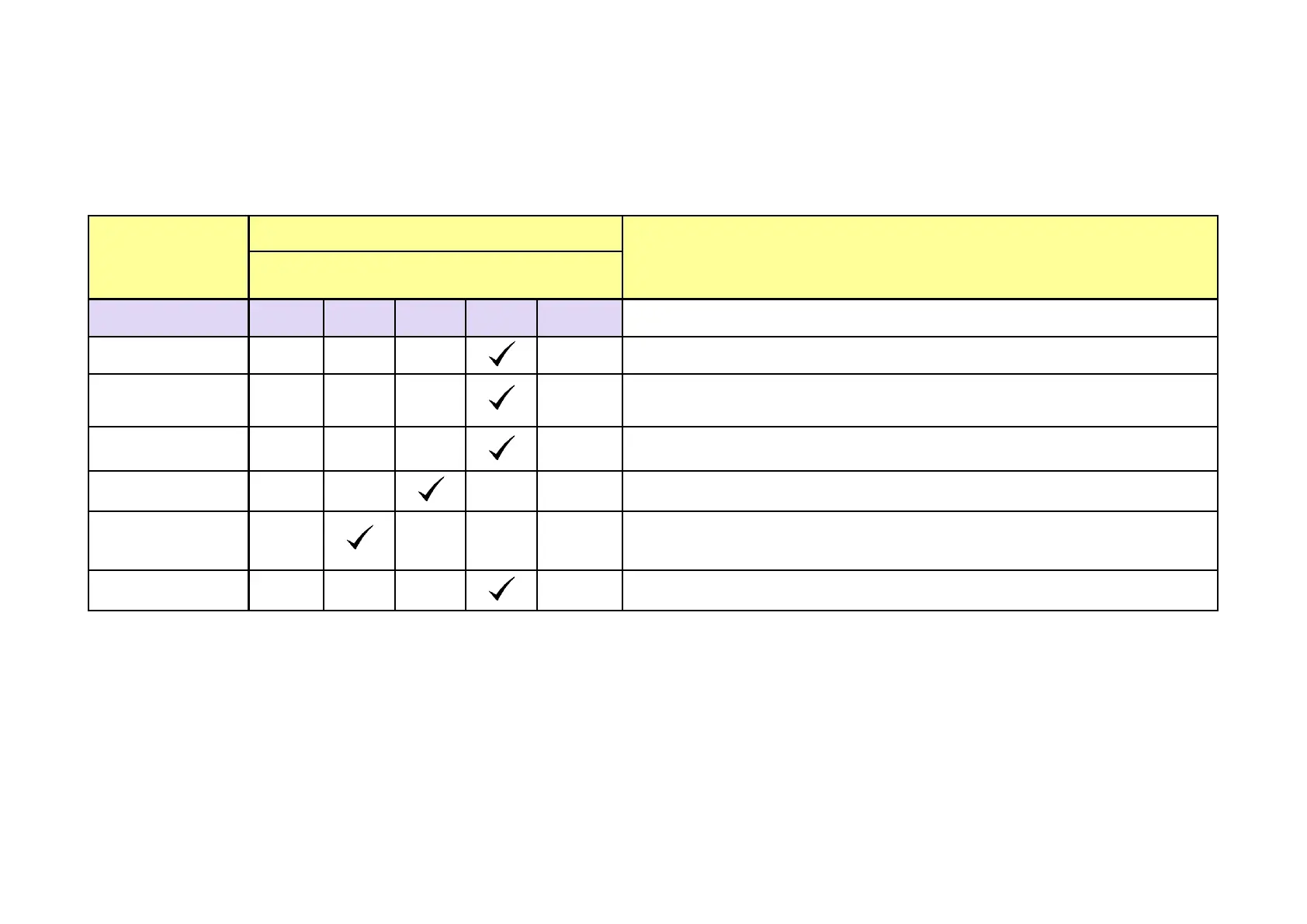

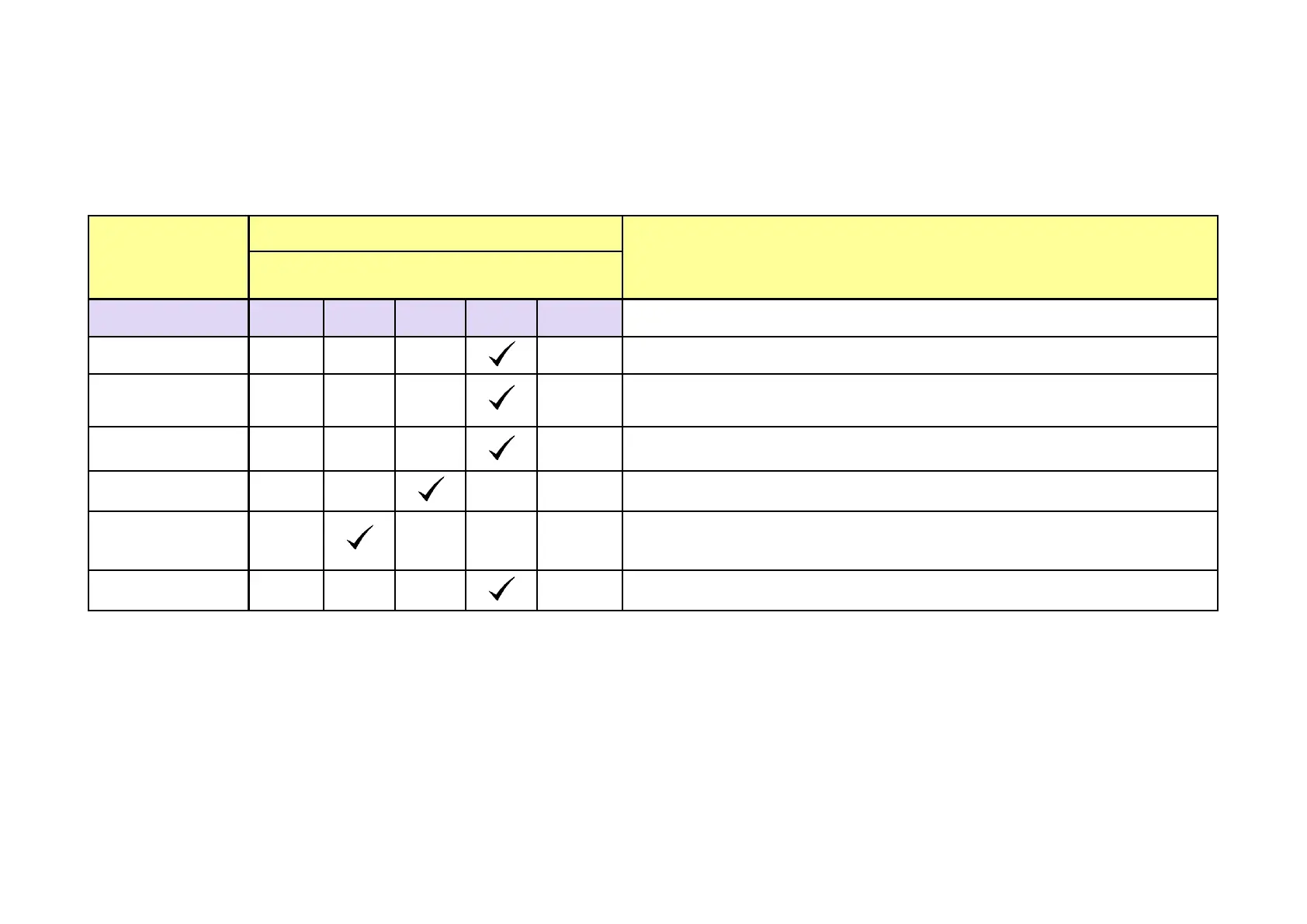

700 SERIES MACHINE ROUTINE MAINTENANCE SCHEDULE

Note: based on a 16-hour day. Daily & yearly checks to be carried out regardless of actual running time.

Weekly, monthly & 3 monthly intervals may be adjusted to suit actual machine running time.

MACHINE AREA /

COMPONENT

FREQUENCY OF TASK

DETAILS OF TASK

3

DAILY WEEKLY MONTHLY MONTHLY YEARLY

BASE LABEL

APPLICATOR

ADDITIONAL

OUTFEED DRIVE

Check condition of nylon gear. Also check it is free running when conveyors are not

engaged onto it. (Refer to parts manual for parts detail).

LABEL

TRANSPORT

BELTS

Check condition and tension of belts

TRANSPORT BELT

ROLLERS

Check for wear or any tightness on bearings and roller assemblies (refer to 700

parts manual for parts detail)

BLOW BARS Check all blow bar holes are clear of debris, tight in their mountings and facing in

the correct direction.

GUIDE ROLLERS

(black rollers at con-

veyor top)

Check all rollers are clean and run freely on their shaft (refer to 700 parts manual for

parts detail)

TRANSPORT BELT

DRIVE

Check smooth rotation of DC motor

Loading...

Loading...