revision: 1

FlexxPump 250/400 DLS

User Manual

10

EN-

3. Description of function

3.1 General information

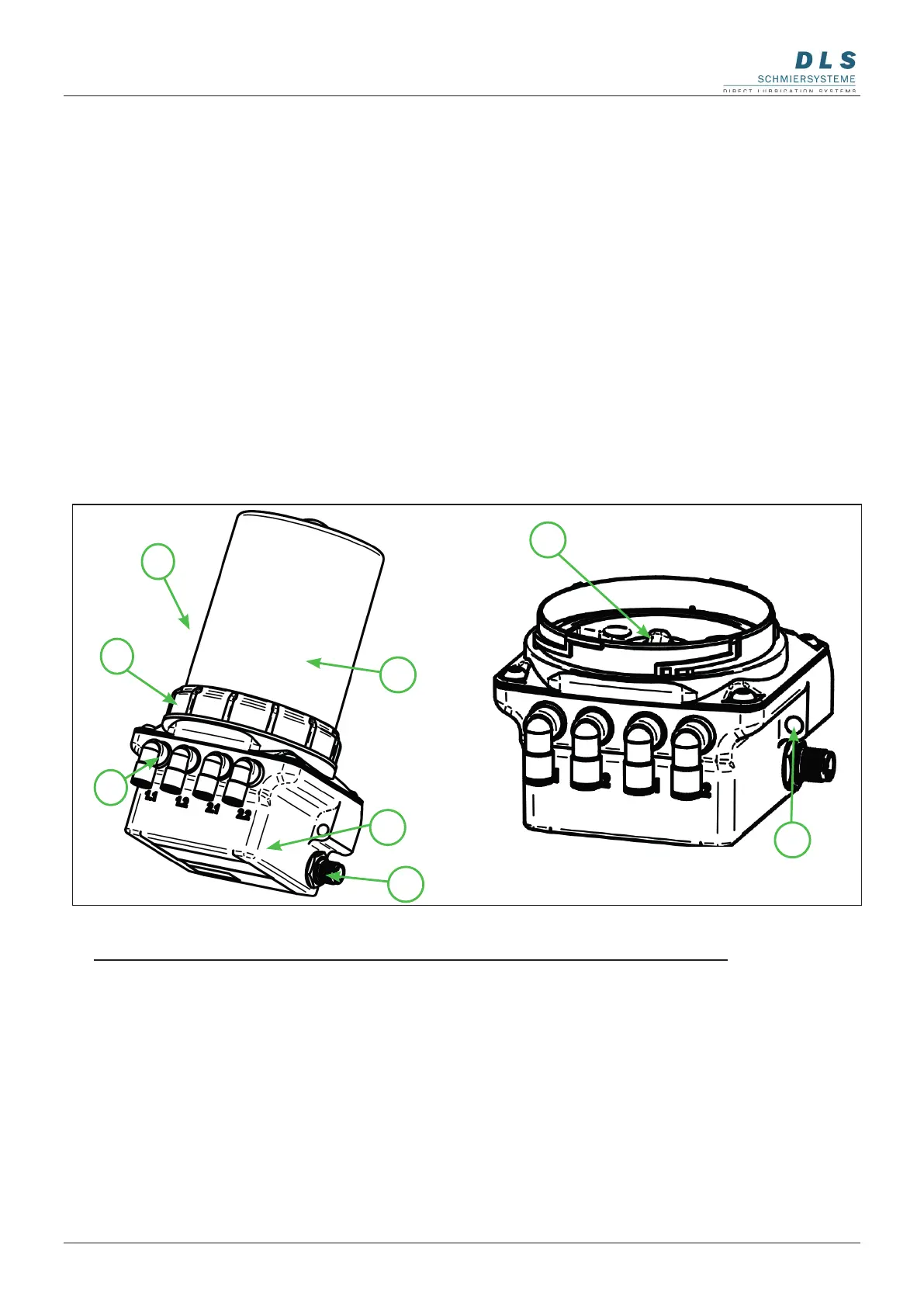

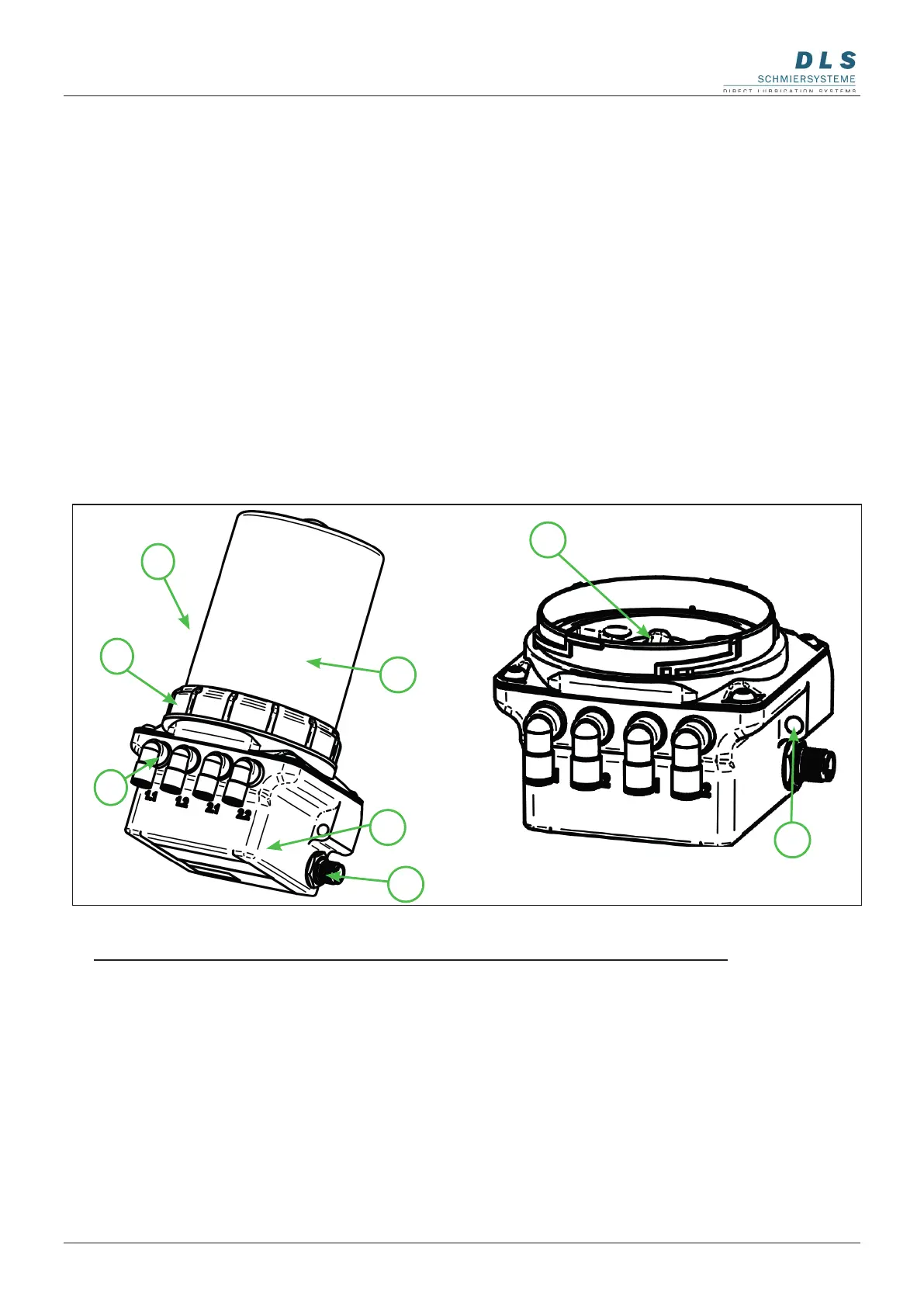

Nr. Description

0 FlexxPump 250/400 DLS

1 Lubricant outlet, outlets (different versions possible)

2 Retaining ring

3 Housing

4 M12x1 electrical interface

5 Nameplate with designation, CE mark and serial number

6 Through hole for assembly

7 Lubricant inlet with thread for cartridge

7

6

Fig. 1: Overview FlexxPump 250/400 DLS

1

2

0

The FlexxPump 250/400 DLS is designed as an extremely compact double piston

pump for autonomous operation with grease as the lubricant. The pistons run force-

controlled and counter-rotating. The FlexxPump 250/400 DLS is available as a version

with one, two, three or four lubricant outlets, see Chapter 5. The outlets are secured by

an integrated non-return valve. Approx. 0.16 cm³ of lubricant is pumped during each

dispensing operation; multiple dispensers can be set one after the other.

The present FlexxPump4 as D version has to be integrated into an external

control (e.g. PLC). The FlexxPump 250/400 DLS has an electrical interface with

which you can control and command the FlexxPump 250/400 DLS. Furthermore,

the FlexxPump 250/400 DLS enables remote monitoring by output signals in

order to be able to query the status and possible error messages (e.g. empty

cartridge). By means of various input signals processed by the microelectronics, the

FlexxPump 250/400 DLS is controlled to supply the lubrication point with the ideal

amount of lubricant.

4

3

5

Loading...

Loading...