revision: 1

FlexxPump 250/400 DLS

User Manual

43

EN-

Before starting any maintenance work, inform yourself about the general safety

instructions (see Chapter 2) and observe the relevant local and operational safety

regulations.

Do not deactivate any protective device without authorization!

The following maintenance schedule must be observed for the Flexx-

Pump 250/400 DLS:

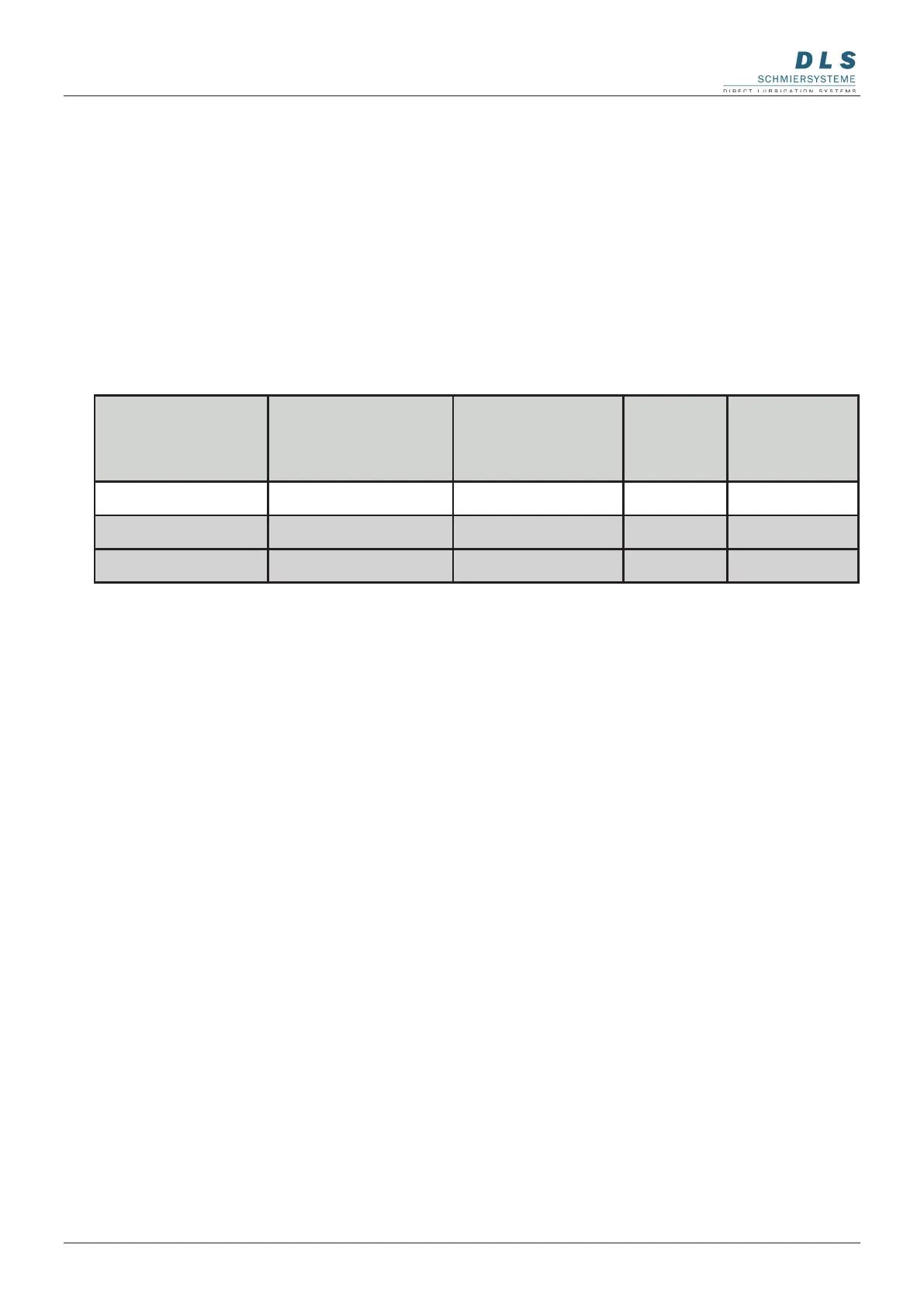

Maintenance Commisioning

After 500

hours or after

3 months

Every

year

If required

Cleaning x x x x*

Visual check x x x x*

Cartridge change x** x*** x*

* Depending on operating conditions and lubricant consumption

** Depending on delivery status (ordered version)

*** Recommendation after 2 years at the latest

9. Maintenance and disposal

9.1 Maintenance schedule

Check the entire lubrication system (FlexxPump 250/400 DLS and any connected

accessories including tubes and distributors) for external damage (e.g. loose or loose-

ned tubes) by a thorough and conscientious visual inspection.

Check the condition of the lubrication point for correct supply of lubricant.

Replace damaged or defective parts immediately to ensure permanent lubrication.

Check the filling level of the cartridge on the FlexxPump 250/400 DLS.

Check possible error messages on the FlexxPump 250/400 DLS and remedy the

causes accordingly.

9.1.1 Visual check

Loading...

Loading...