Maintenance Section

-153-

Parking Brake

NOTE:

The parking brake is required to be

adjusted to hold the lift truck with capacity

load on a 15% grade.

If there is a 15% grade in your workplace,

engage a capacity load and drive over to

the grade. If the maximum grade in your

workplace is less than 15% or if the

maximum load carried by the lift truck is

less than the lift truck's load capacity, pick

up the maximum load and drive to the

steepest grade in your workplace.

1.

Raise the forks or load engaging attachment

about 30 cm (12 in) from the floor.

2.

Drive forward up the grade, or in reverse down the

grade, and stop the lift truck with the service

brakes.

3.

Engage the parking brake and release the service

brakes.

4.

If the lift truck moves down the grade, control its

speed with the service brakes, release the parking

brake and return directly to the inspection area.

5.

Park the lift truck, engage the parking brake, shift

the direction control lever to NEUTRAL, lower the

forks or load engaging attachment to the floor,

shut OFF the engine, remove the key, chock the

tires, terminate the inspection, tag the lift truck "Do

Not Operate" and immediately report the failure of

the parking brake to hold the lift truck.

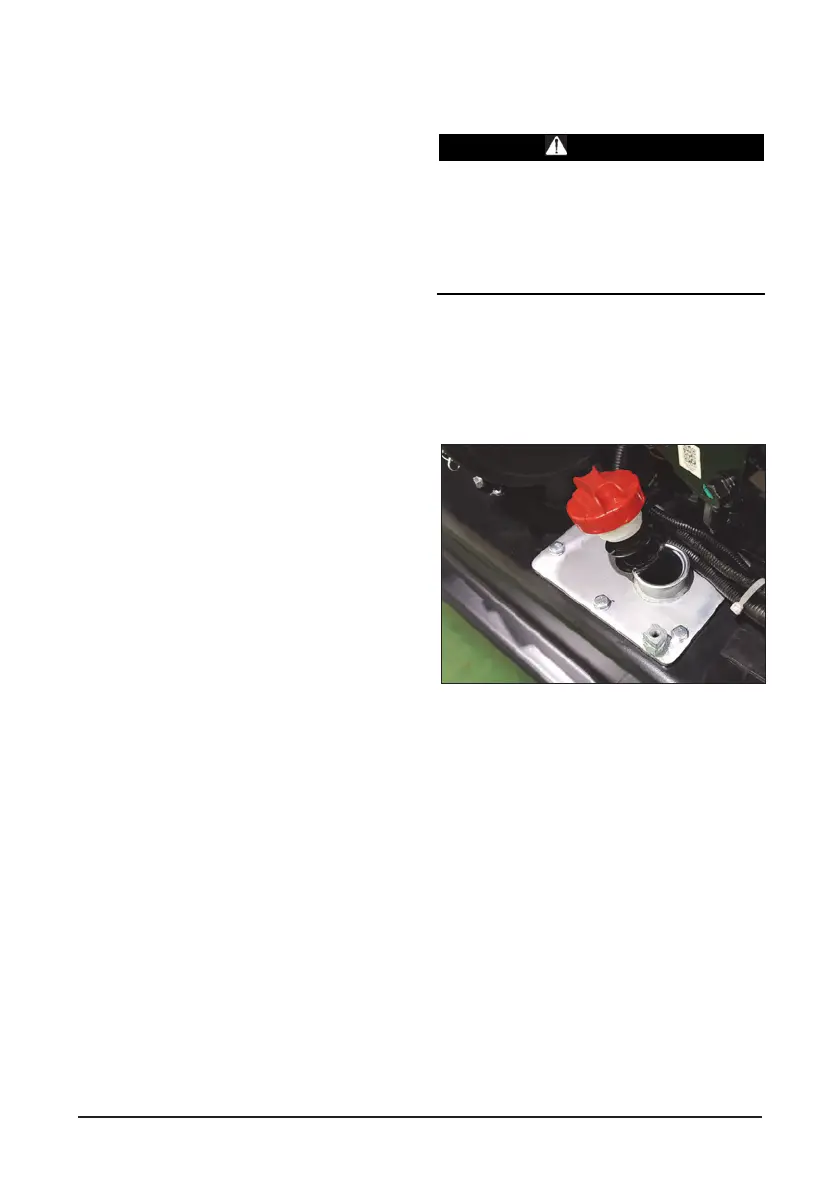

Hydraulic Oil Level – Check

WARNING

At operating temperature, the hydraulic tank is

hot and under pressure.

Hot oil can cause burns.

Remove the filter cap only when the engine is

stopped, and the cap is cool enough to touch

with your bare hand. Remove the filter cap slowly

to relieve pressure.

Operate the lift truck for a few minutes to warm the

oil. Park the lift truck on a level surface, with the forks

lowered, mast tilted back, parking brake engaged,

transmission in NEUTRAL and the engine stopped.

Raise the hood and seat assembly. Make sure the

air lift cylinder securely holds the hood open.

Remove the dip stick/filter cap. Maintain the oil level

to the FULL mark on the dip stick/filter cap.

Loading...

Loading...