Maintenance Section

-160-

4. Wipe sealing surface of oil filter element

mounting base. Make sure the entire old gasket

is removed.

5. Before installing a new filter element, apply a

small amount of clean engine oil to the filter

element gasket.

6. Install the new filter element. When the gasket

contacts the base, tighten it 3/4 of a turn more.

Do not over-tighten.

7. Raise the lift truck, remove the blocking and

lower the lift truck.

8. Fill the crankcase. See “Refill Capacities”.

9. Start the engine and allow the oil to fill the filter

and passages.

10. Check for oil leaks.

DM02VA/P

11.

Stop the engine and measure the oil level.

Maintain the oil level to the FULL mark on the dip

stick.

12. Close hood and seat assembly

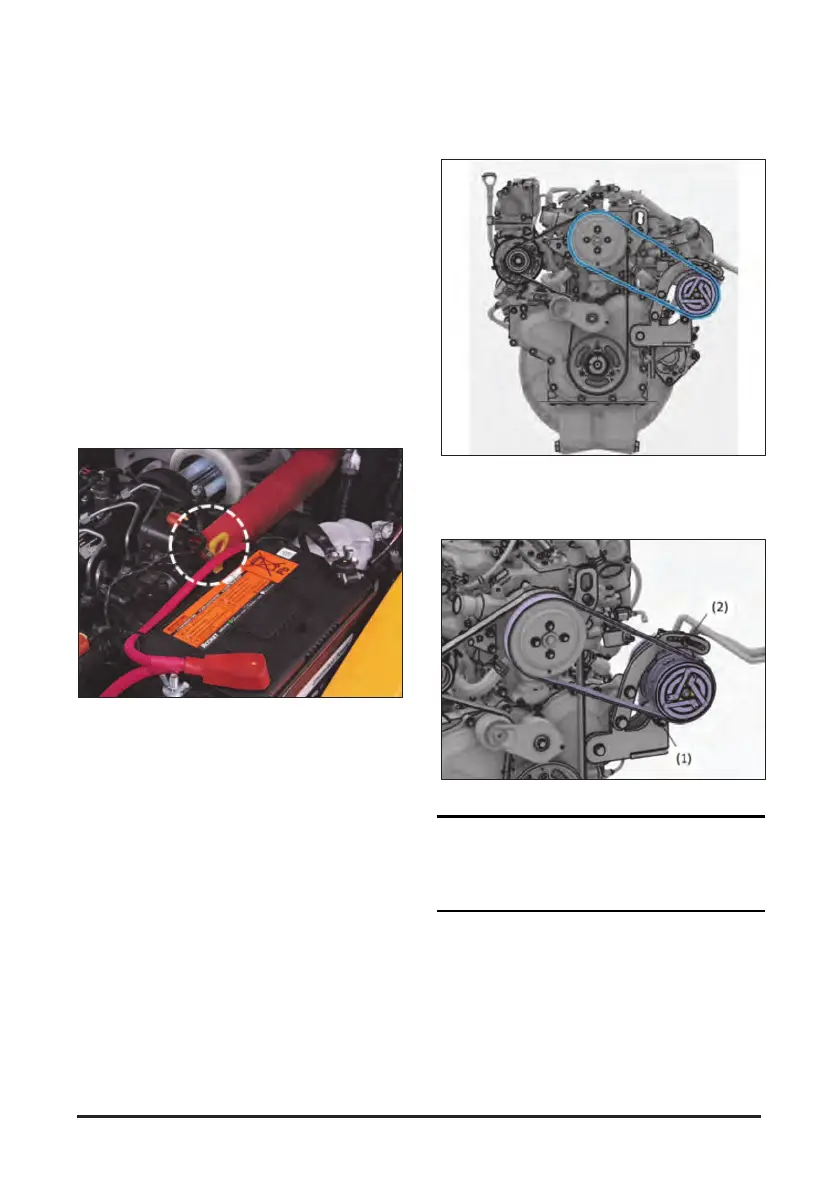

Belts - Check, Adjust (Only for Air-

con Compressor)

Typical Example

1. Check the condition and adjustment of the belt.

Correct adjustment allows 10 mm (3/8 inch)

deflection under 110 N (25 lb) of force.

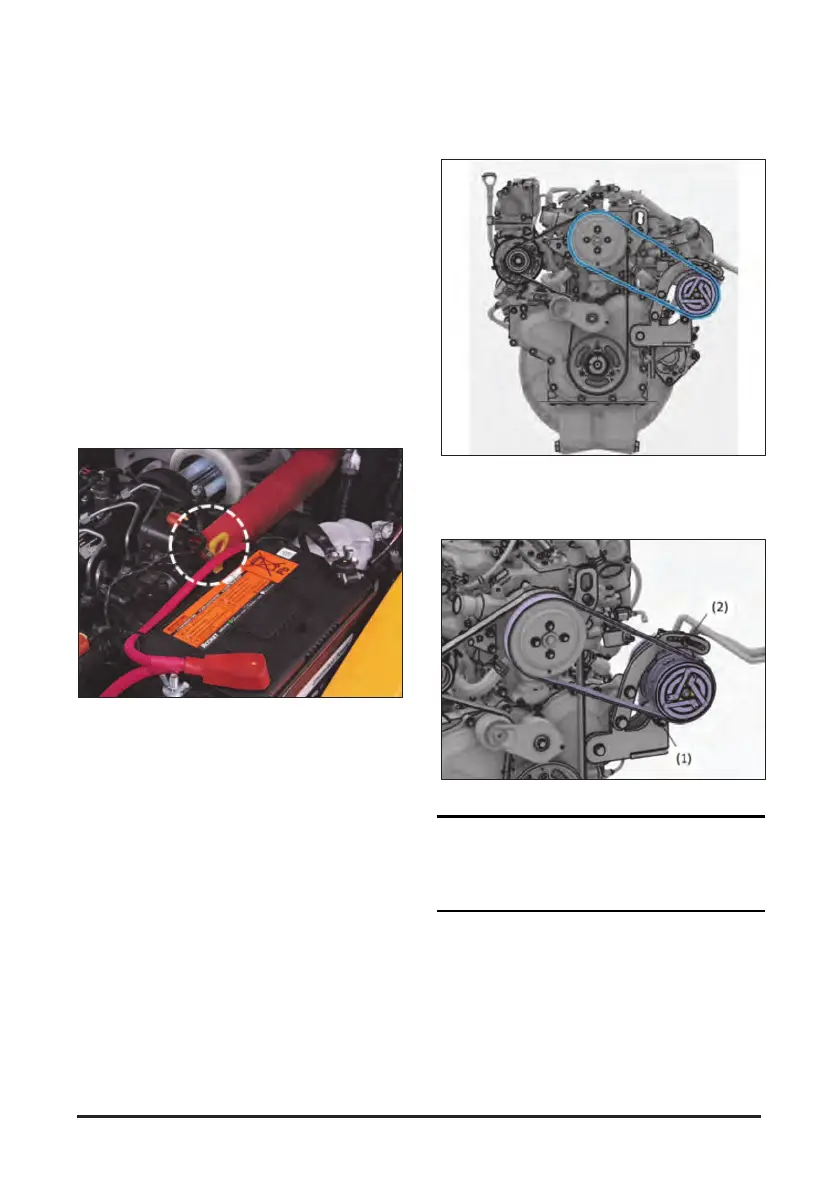

NOTICE

Failure to loosen air-con compressor mounting bolt

(2) will cause excessive stress and break the

alternator mounting ear.

2. To adjust the tension of the air-con compressor

drive belt, loosed the adjustment bolts (1) and

(2) and move the belt, as necessary.

Loading...

Loading...