Maintenance Section

-171-

Every 2000 Service Hours or Yearly

You must read and understand the warnings and instructions contained in the Safety section of this manual,

before performing any operation or maintenance procedure.

Drive Axle Oil, Transmission Oil,

Oil Filter & Strainer - Clean,

Change

See the topic, "Drive axle Oil, Transmission Oil, Oil

Filter & Strainer - Clean, Change" in First 50-100

Service hours or a week.

Engine Valve Lash (Diesel Engine

Only) – Check, Adjust

See topic “Engine valve Lash (Diesel Engine Only) –

Check, Adjust”. In Every 1000 Service Hours or 6

Months.

Steer Wheel Bearings -

Reassemble

Park the lift truck level with the forks lowered, parking

brake engaged, transmission in NEUTRAL and the

engine stopped.

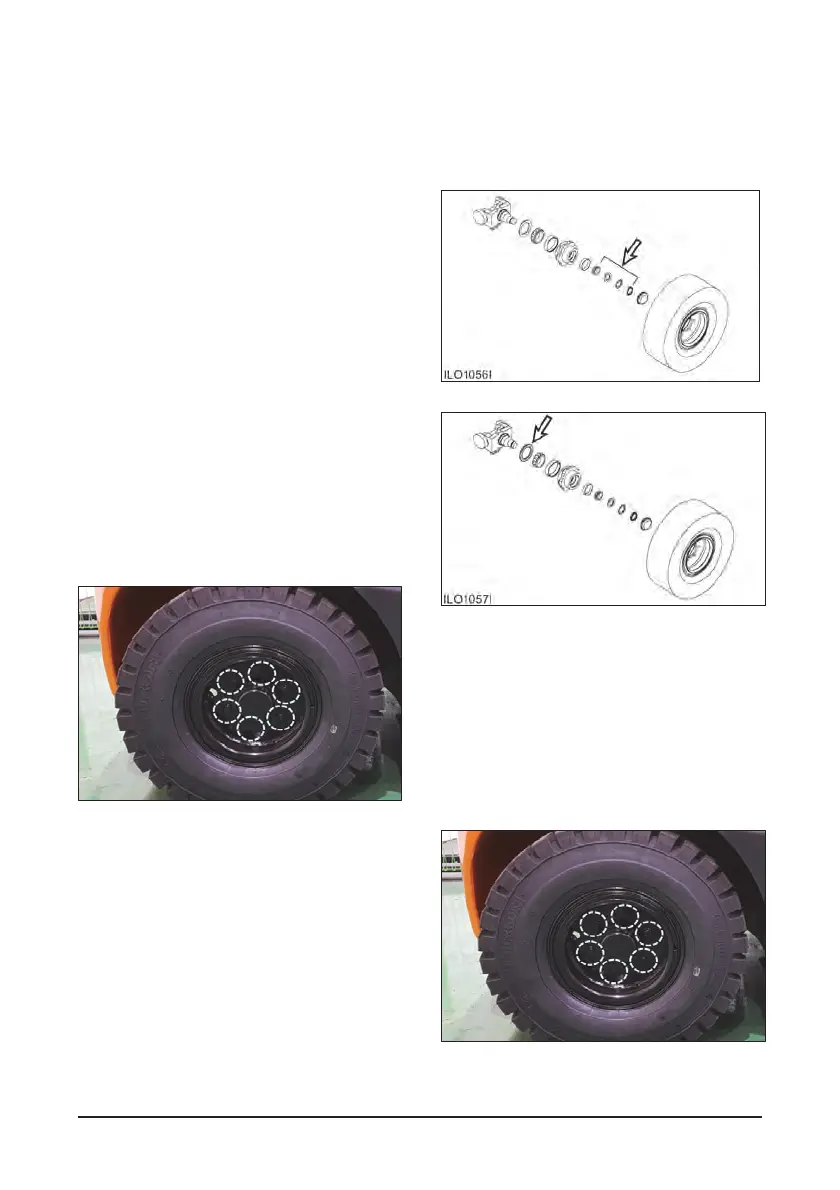

Typical Example

1. Lift the steer wheels off the ground. Place stands

or blocking under the frame and steer axle to

support the lift truck.

2. Remove the hub cap which is pressed into the

wheel hub.

3. Straighten the lock washer tangs.

4. Remove the locknut, lock washer and flat washer.

5.

Remove the outer wheel bearing.

Remove the wheel assembly. Examine the seal

for damage and wear. Replace the seal if

necessary.

6. Remove the inner bearing. Clean and lubricate

the steering knuckle. Reassemble both the inner

and outer bearing cones.

7. Install the inner bearing. Lubricate the seal and

install the wheel assembly on the knuckle.

8. Install the outer wheel bearing and the out

washer. Install a new lock washer and fit the

locknut.

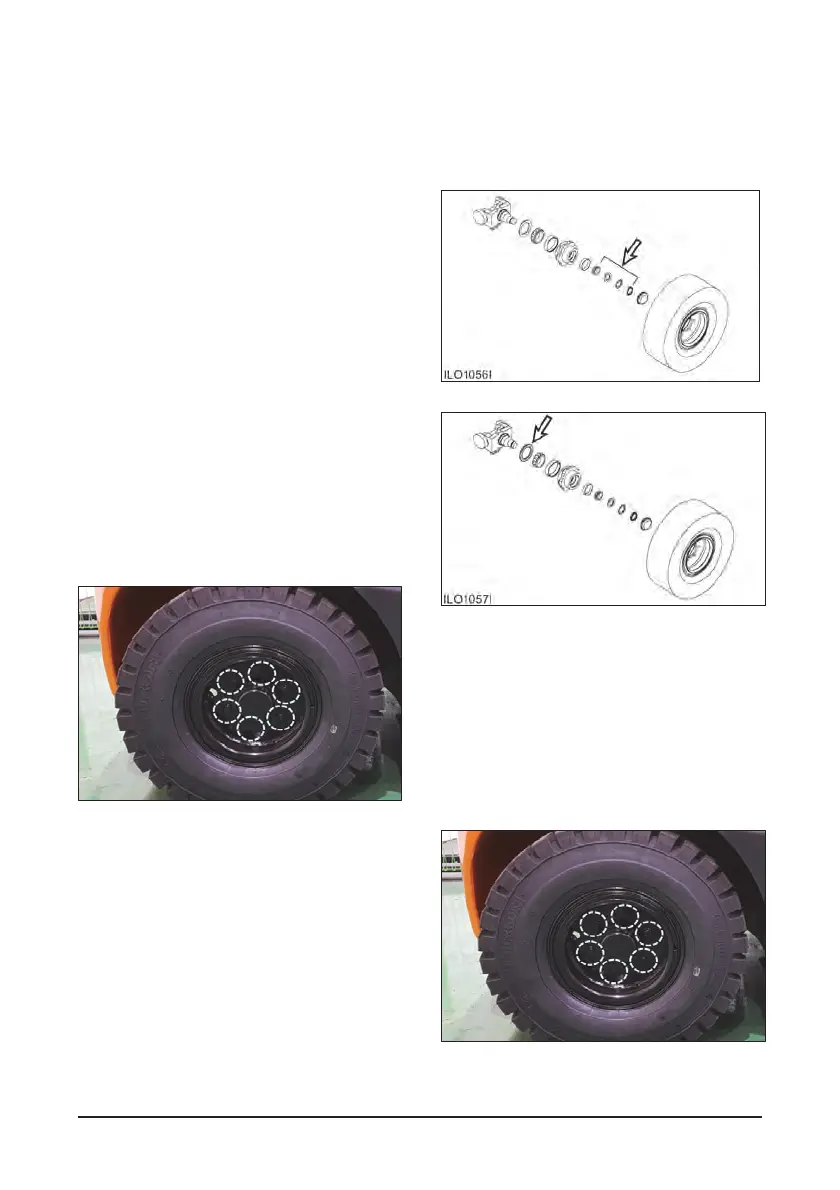

Typical Example

9. Tighten the locknut to 135 N•m (100 lb•ft), while

Loading...

Loading...