Operation&MaintenanceManualNOISEEMISSION

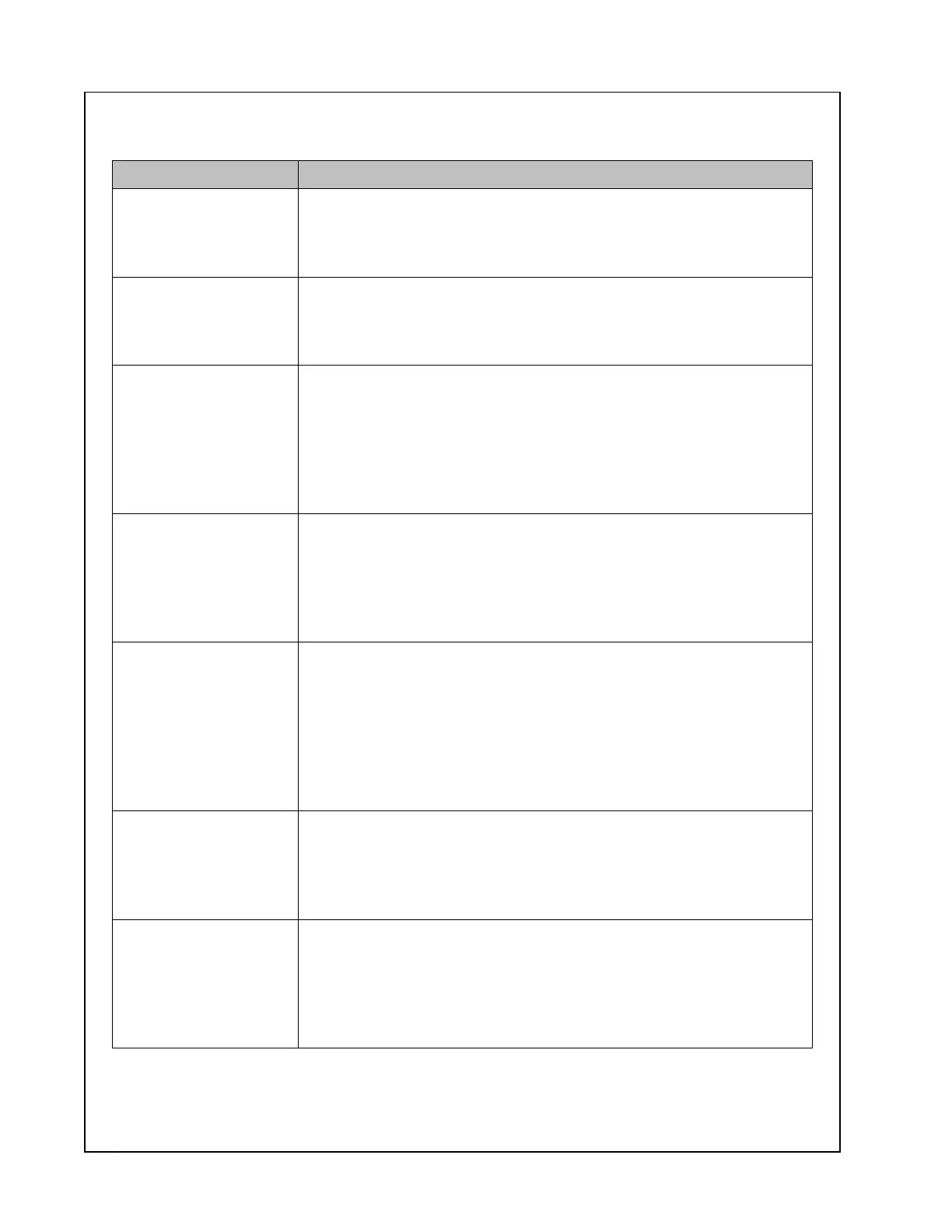

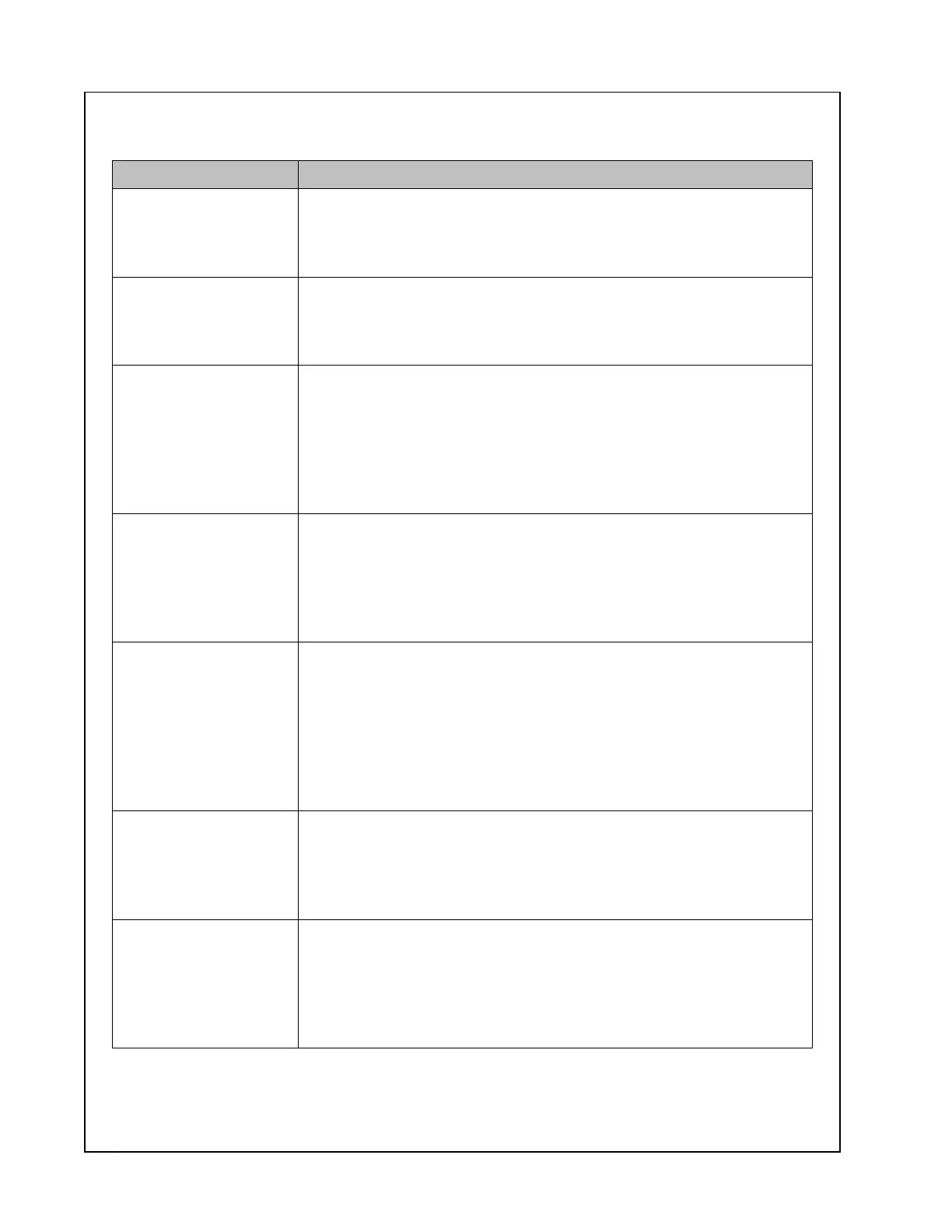

MaintenanceSchedule

PERIODDESCRIPTION

AsDetected

COMPRESSEDAIRLEAKS

Correctallcompressedairleaksduringtherstshutdownperiod

afterdiscovery.Ifsevereenoughtocauseseriousnoiseproblems

andefciencyloss,shutdownimmediatelyandcorrecttheleak(s).

AsDetected

SAFETYANDCONTROLSYSTEMS

Repairorreplaceallsafetyandcontrolsystemsorcircuitsas

malfunctionoccurs.Nocompressorshouldbeoperatedwitheither

systembypassed,disabled,ornonfunctional.

Daily

ACOUSTICMATERIALS

Indailyinspections,observethesematerials.Maintainallacoustic

materialasnearlyaspossibleinitsoriginalcondition.Repairor

replaceallsectionsthathave:1)sustaineddamage,2)have

partiallyseparatedfrompanelstowhichtheywereattached,3)are

missing,orhaveotherwisedeterioratedduetosevereoperatingor

storageconditions.

100HOURSFASTENERS

Allfastenerssuchashinges,nuts,bolts,clamps,screws,rivets,

andlatchesshouldbeinspectedforloosenessaftereach100

hoursofoperation.Theyshouldberetightened,repaired,orif

missing,replacedimmediatelytopreventsubsequentdamageand

noiseemissionincrease.

100HOURSENCLOSUREPANELS

Enclosurepanelsshouldbeinspectedat100houroperational

intervals.Allpanelsthatarewarped,punctured,torn,orotherwise

deformed,suchthattheirnoisecontainmentfunctionisreduced,

shouldberepairedorreplacedbeforethenextoperationinterval.

Doors,accesspanels,andhatchclosuresespecially,shouldbe

checkedandadjustedatthistimetoensurecontinuousseating

betweengasketoracousticmaterialandthematingframe.

100HOURSAIRINTAKEANDENGINEEXHAUST

Engineandcompressorairintakeandengineexhaustsystems

shouldbeinspectedaftereach100hoursofoperationforloose,

damaged,ordeterioratedcomponents.Repairsorreplacements

shouldbemadebeforethenextperiodofuse.

250HOURSCOOLINGSYSTEMS

Allcomponentsofthecoolingsystemforenginewaterand

compressoroilshouldbeinspectedevery250hoursofuse.

Anydiscrepanciesfoundshouldbecorrectedbeforeplacingthe

compressorbackinoperation.Unrestrictedairowovertheradiator

andoilcoolermustbemaintainedatalltimesduringoperation.

28

Loading...

Loading...