35

26 of 35

FLEXIBLE BATCH BROILER

EQUIPMENT

MANUAL

April 1, 2007

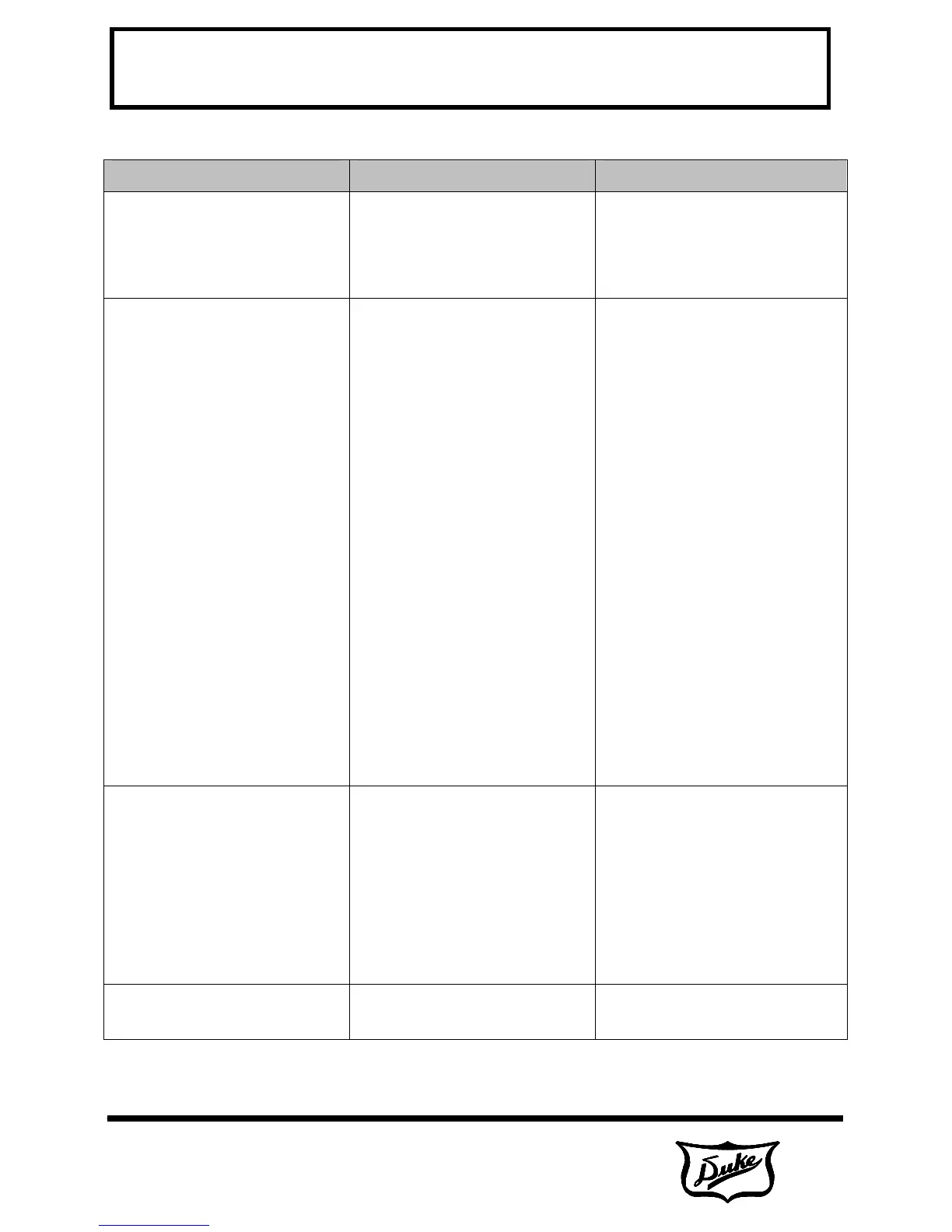

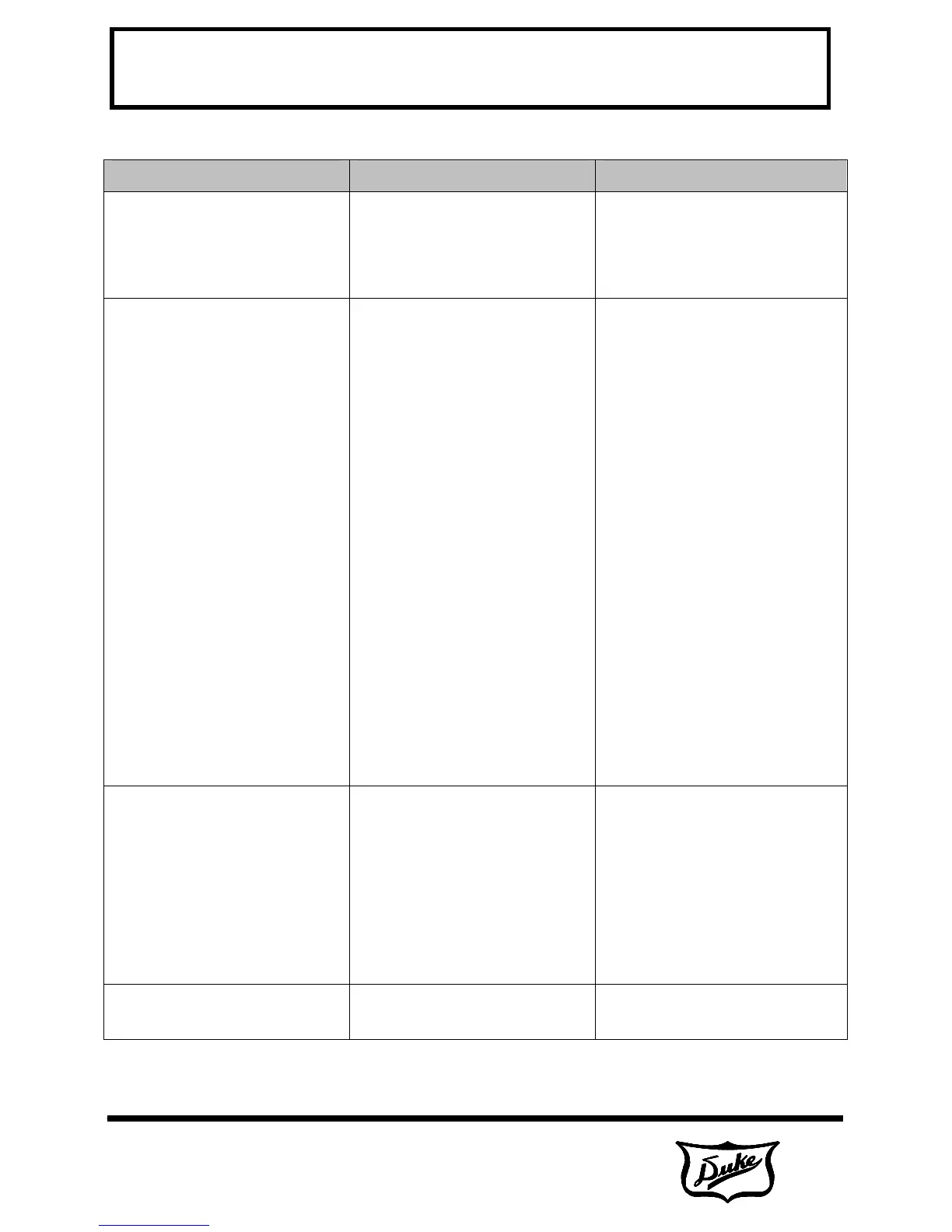

E. Troubleshooting

SYMPTOM CAUSE REMEDY

Control display does not light up No power Ensure broiler is plugged into a

proper voltage/Hz receptacle (per

name plate rating) and receptacle

as power. Check dedicated

circuit breaker.

Raw or undercooked product

with no controller error

messages displayed.

Product not loaded properly.

Product button was depressed

prior to loading product.

Wrong product button was

depressed.

Lower burner not lighting

properly. (Observe bottom

burner through slits in lower

grease tray)

Infrared burners not lighting

properly. (Observe Infrared

through discharge end of broiler.

Note: Burners should remain lit

in idle mode)

Review loading technique.

Ensure product button is

depressed immediately after

product is loaded into broiler.

Ensure proper product button is

being depressed.

If broiler is hot, attempt to clean

burner in place with broiler

cleaning tool.

If broiler is cold or allowed to cool

down, remove lower burner by

removing access panels, clean,

and reinstall. Remove lower

flame sensor and clean with a

soft cloth & isopropyl alcohol.

Remove upper control

compartment panel and clean 2

upper flame sensors with a soft

cloth & isopropyl alcohol.

Clean flame sensor tube with

flame sensing tube cleaning

brush.

Conveyor belt will not move to

discharge product.

Conveyor belt is being

obstructed

Observe for obstructions by

manually rotating conveyor belt

from discharge end of broiler

using broiler cleaning tool.

Ensure discharge scraper is

properly in place.

Ensure docking plate is properly

in place.

Ensure flame arrestor is properly

in place.

Loader is not able to be pushed

completely into cooking chamber

Docking plate is not properly in

place.

Ensure docking plate and locking

tab are correctly in place.

Loading...

Loading...