35

27 of 35

FLEXIBLE BATCH BROILER

EQUIPMENT

MANUAL

April 1, 2007

E. Troubleshooting (cont’d)

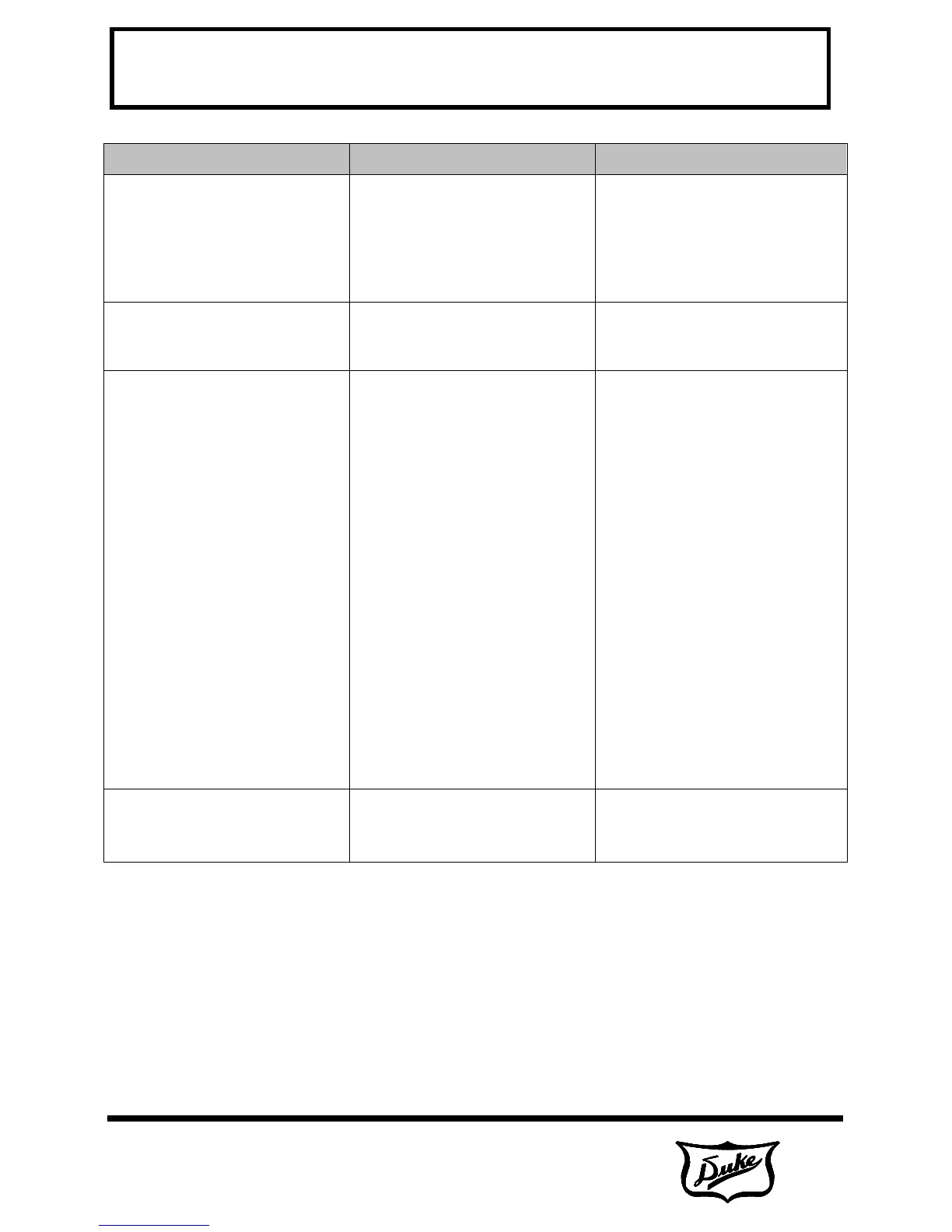

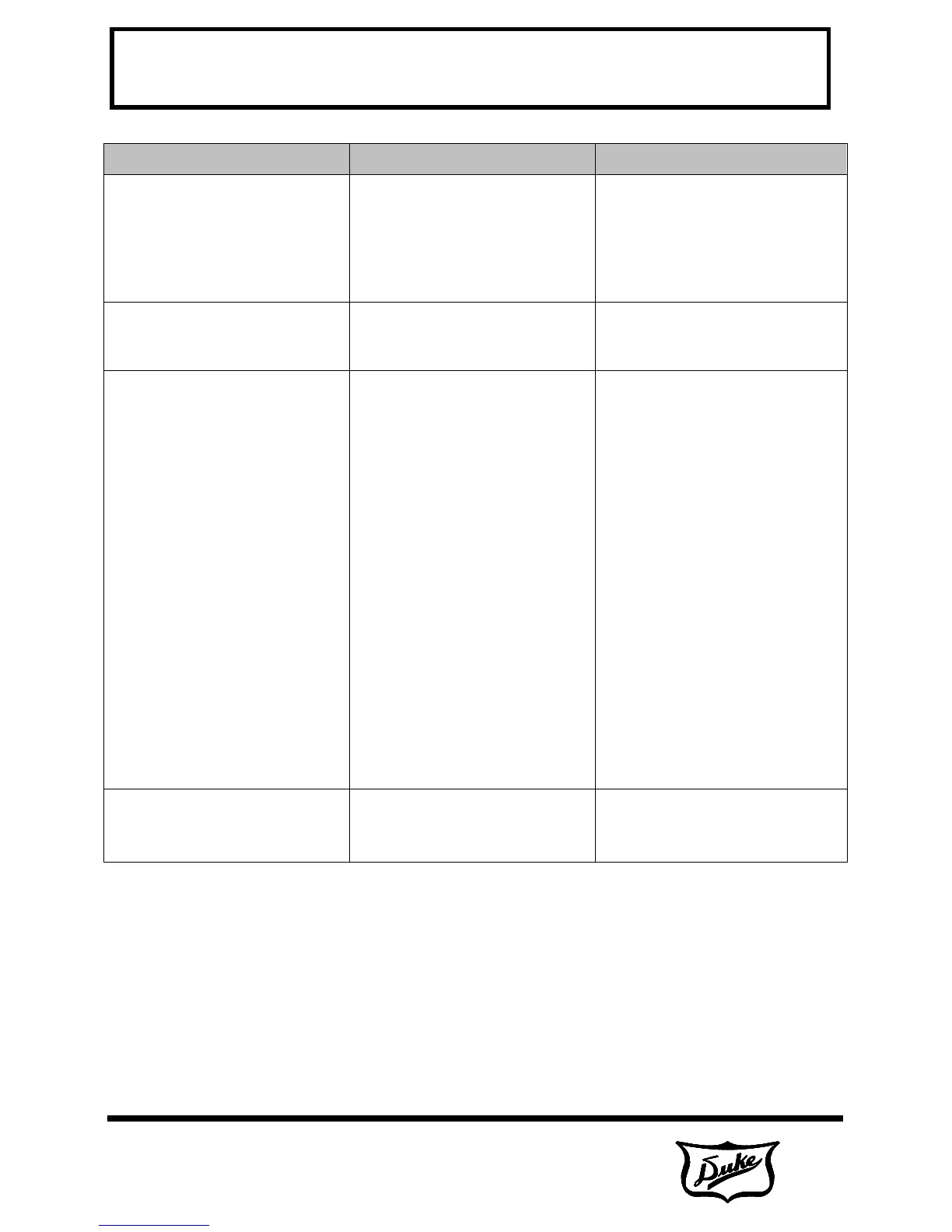

SYMPTOM CAUSE REMEDY

Product is getting stuck or

mangled upon loading

Docking plate is not properly in

place

Flame arrestor is not properly in

place

Ensure docking plate and locking

tab are correctly in place.

Ensure flame arrestor is correctly

in place and tabs are slotted

correctly.

Control display is reading “Hi”

Contact Duke Manufacturing Co.

or a Duke Authorized Service

agent.

Control display is reading “Lo”

Lower burner not lighting

properly. (Observe bottom

burner through slits in lower

grease tray)

Infrared burners not lighting

properly. (Observe Infrared

through discharge end of broiler.

Note: Burners should remain lit

in idle mode)

Grease pan is not installed

Impedance pan or catalyst is not

installed.

If broiler is hot, attempt to clean

burner in place with broiler

cleaning tool.

If broiler is cold or allowed to cool

down, remove lower burner by

removing access panels, clean,

and reinstall. Remove lower

flame sensor and clean with a

soft cloth & isopropyl alcohol.

Remove upper control

compartment panel and clean 2

upper flame sensors with a soft

cloth & isopropyl alcohol.

Clean flame sensor tube with

flame sensing tube cleaning

brush.

Install grease pan

Install impedance pan or catalyst

Control display is reading “Prob”

Contact Duke Manufacturing Co.

or a Duke Authorized Service

agent.

Loading...

Loading...