–

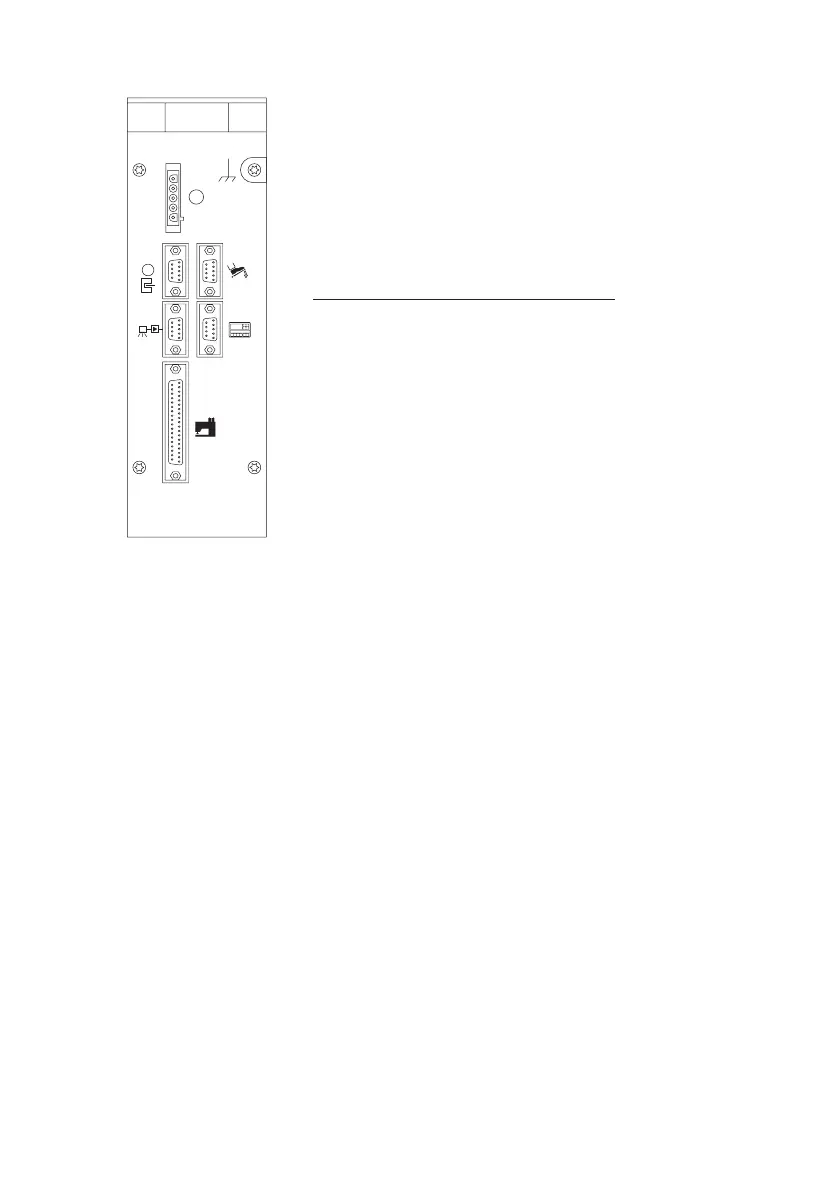

Connect the 9-pole SuB-D plug of the Hall-effect sensor to the

bushing “B18" (IPG / HSM / LSM) of the Efka control drive DA321G.

–

Set the correct machine class with parameter F-290 according to

the corresponding parameter sheet 9800 331104 PBXX.

–

In order to position the machine correctly and to optimize all

functions the following parameters must still be set:

Parameter F-111: set to 3,000 rpm or less.

Parameter F-270: set to 6 (selection according to the position sensor)

Parameter F-272: can be calculated according to the formula below:

Motor pulley diameter (teeth)

x 1000

Machine pulley diameter (teeth)

Inserted needle: up to a thickness of 160.

Due to the gear reduction of 1.55:1 the maximum possible speed

is 3,000 rpm.

Due to the new transmission ratio of 1,55:1 a higher torque and a

higher penetration force of the needle of about 30% above a

transmission rate of 1:1 is achieved.

In order to achieve an even higher penetration force, the parameter

F-225 can be set from value “0" to value ”1".

It may happen, that the motor produces a snarling noise.

If this is the case, the toothed belt between motor and machine must

be tightened.

21

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B . . .

B 4 1

M

A

–

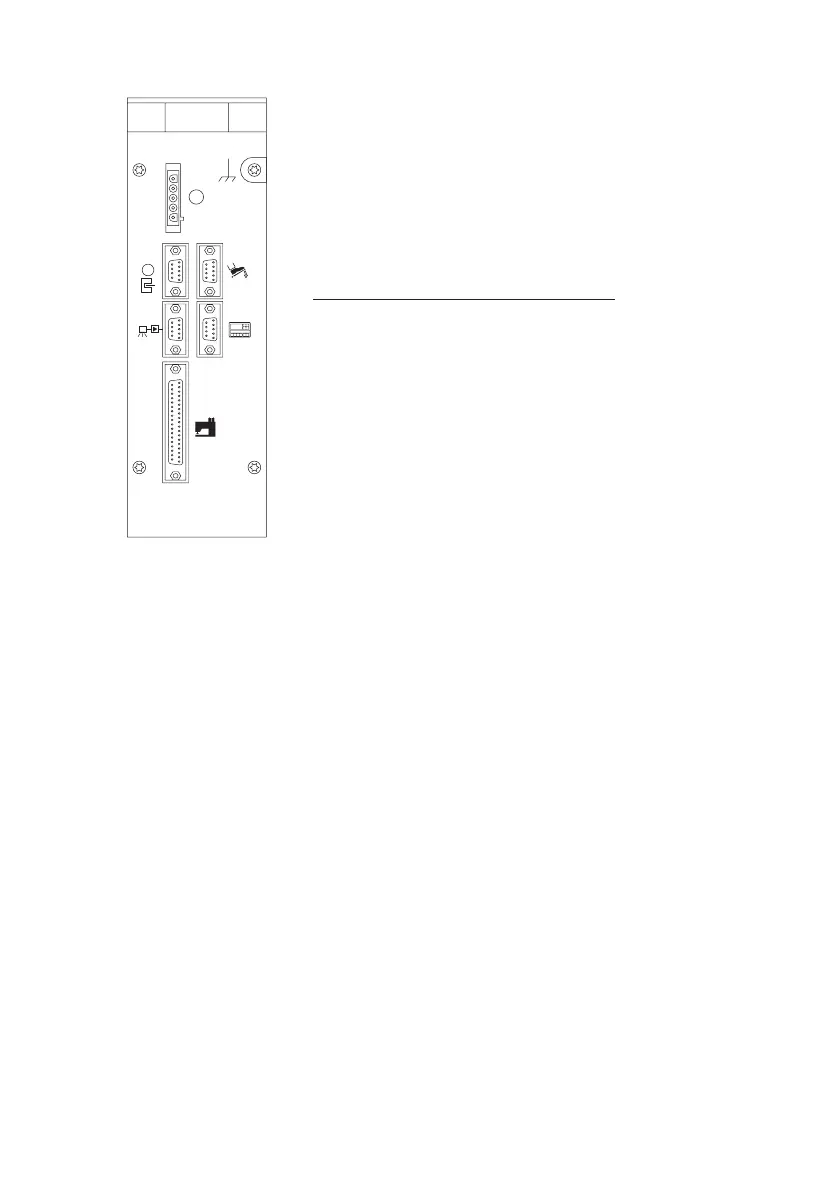

Connect the 9-pole SuB-D plug of the Hall-effect sensor to the

bushing “B18" (IPG / HSM / LSM) of the Efka control drive DA321G.

–

Set the correct machine class with parameter F-290 according to

the corresponding parameter sheet 9800 331104 PBXX.

–

In order to position the machine correctly and to optimize all

functions the following parameters must still be set:

Parameter F-111: set to 3,000 rpm or less.

Parameter F-270: set to 6 (selection according to the position sensor)

Parameter F-272: can be calculated according to the formula below:

Motor pulley diameter (teeth)

x 1000

Machine pulley diameter (teeth)

Inserted needle: up to a thickness of 160.

Due to the gear reduction of 1.55:1 the maximum possible speed

is 3,000 rpm.

Due to the new transmission ratio of 1,55:1 a higher torque and a

higher penetration force of the needle of about 30% above a

transmission rate of 1:1 is achieved.

In order to achieve an even higher penetration force, the parameter

F-225 can be set from value “0" to value ”1".

It may happen, that the motor produces a snarling noise.

If this is the case, the toothed belt between motor and machine must

be tightened.

21

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B . . .

B 4 1

M

A

–

Connect the 9-pole SuB-D plug of the Hall-effect sensor to the

bushing “B18" (IPG / HSM / LSM) of the Efka control drive DA321G.

–

Set the correct machine class with parameter F-290 according to

the corresponding parameter sheet 9800 331104 PBXX.

–

In order to position the machine correctly and to optimize all

functions the following parameters must still be set:

Parameter F-111: set to 3,000 rpm or less.

Parameter F-270: set to 6 (selection according to the position sensor)

Parameter F-272: can be calculated according to the formula below:

Motor pulley diameter (teeth)

x 1000

Machine pulley diameter (teeth)

Inserted needle: up to a thickness of 160.

Due to the gear reduction of 1.55:1 the maximum possible speed

is 3,000 rpm.

Due to the new transmission ratio of 1,55:1 a higher torque and a

higher penetration force of the needle of about 30% above a

transmission rate of 1:1 is achieved.

In order to achieve an even higher penetration force, the parameter

F-225 can be set from value “0" to value ”1".

It may happen, that the motor produces a snarling noise.

If this is the case, the toothed belt between motor and machine must

be tightened.

21

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B . . .

B 4 1

M

A

–

Connect the 9-pole SuB-D plug of the Hall-effect sensor to the

bushing “B18" (IPG / HSM / LSM) of the Efka control drive DA321G.

–

Set the correct machine class with parameter F-290 according to

the corresponding parameter sheet 9800 331104 PBXX.

–

In order to position the machine correctly and to optimize all

functions the following parameters must still be set:

Parameter F-111: set to 3,000 rpm or less.

Parameter F-270: set to 6 (selection according to the position sensor)

Parameter F-272: can be calculated according to the formula below:

Motor pulley diameter (teeth)

x 1000

Machine pulley diameter (teeth)

Inserted needle: up to a thickness of 160.

Due to the gear reduction of 1.55:1 the maximum possible speed

is 3,000 rpm.

Due to the new transmission ratio of 1,55:1 a higher torque and a

higher penetration force of the needle of about 30% above a

transmission rate of 1:1 is achieved.

In order to achieve an even higher penetration force, the parameter

F-225 can be set from value “0" to value ”1".

It may happen, that the motor produces a snarling noise.

If this is the case, the toothed belt between motor and machine must

be tightened.

21

B 7 7 6

V 8 . .

B 1 8

L S M . . .

B 2

M

B 8 0

E B . . .

B 4 1

M

A

Loading...

Loading...