06/2011 - Art. Nr. 13 018 118C

46

Regulating the burner for gas

operation

•

Open the gas ball valve.

•

Set the gas and air pressure

switches to the minimum setting.

•

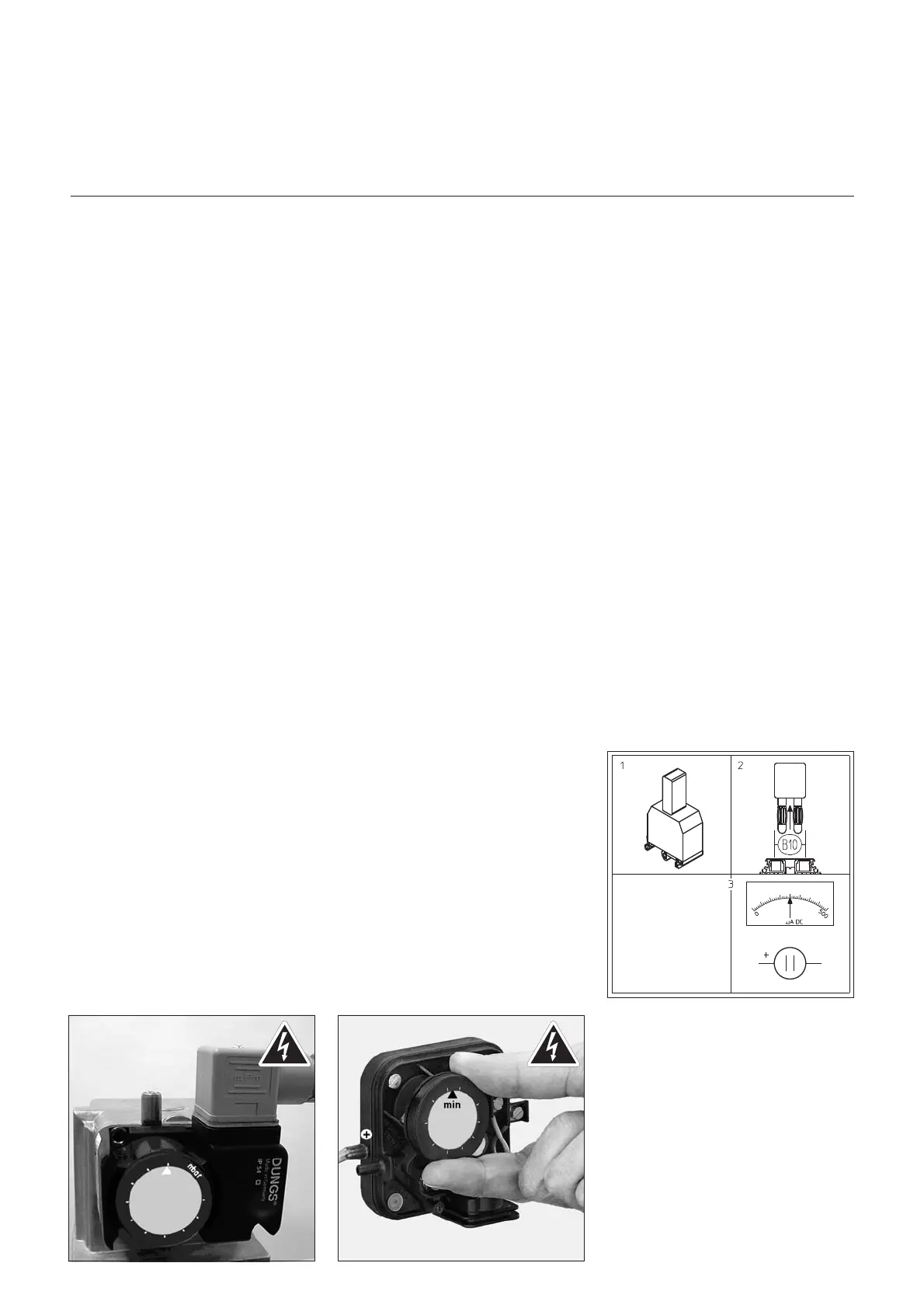

Connect a micro-amperemeter

(0-500µA) instead of the measure

-

ment bridge (check polarity).

•

Press S1/H10.1 - S29J -S2K -

S4 Gas.

•

Switch on the boiler control system.

•

Unlock the control and safety unit.

•

Gas leak test device activates the

burner after a successful check.

•

After the flame has formed, check

the combustion values (CO,CO

2

).

•

Check the UV flow (target value

between 200 and 500 μA).

•

Read the gas flow rate from the gas

counter.

•

Increase the power to high load by

pressing + on the pulsation switch S3.

• Check the exhaust gas values.

Re-adjust the gas/air ratio depending

on the measurement value:

–

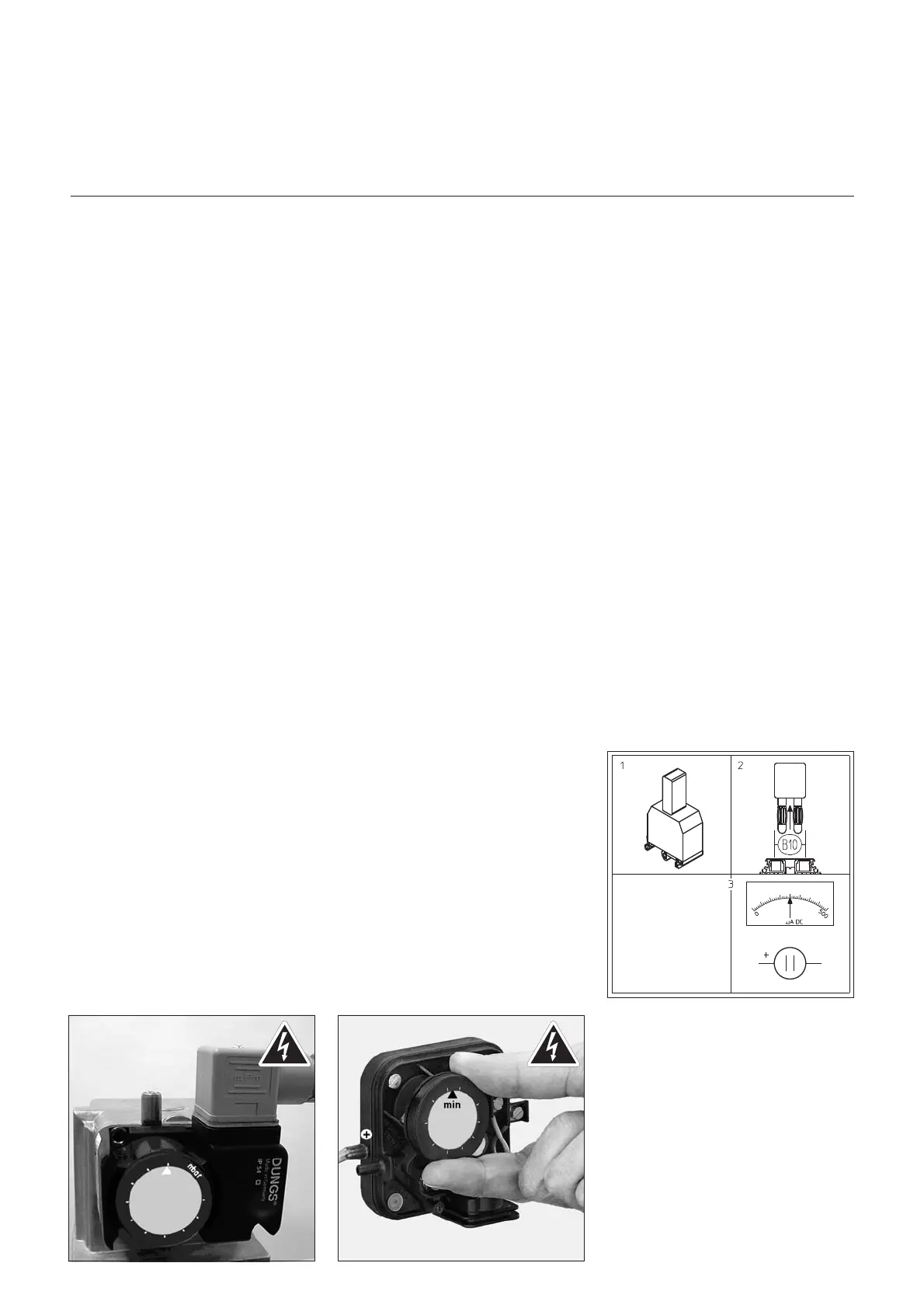

with SKP, act on adjustment screw

R. To do this, remove the upper

cover. Higher CO

2

in direction +.

Lower CO

2

in direction -. (see

symbols on the top SKP70 page 34)

–

with MBVEF valve, act on screw V.

Higher CO

2

in direction of greater scale

setting. Lower CO

2

in direction of

smaller scale setting. (see page 34)

•

To achieve the desired level of effi

-

ciency, use the CO

2

and exhaust

gas temperature settings recom

-

mended by the boiler manufacturer.

•

Check the UV flow (target value

between 200 and 500 μA).

•

Read the gas flow rate from the gas

counter.

•

Bring the burner to low load and

check the combustion values.

Depending on the measurement

value, adjust screw D on the SKP

regulator, or screw N on the MBVEF

regulator.

•

Define the desired partial load with

key S3. To do this, re-adjust cam V

as required.

•

Check the exhaust gas values again

and re-adjust the gas/air ratio

depending on the measurement

value.

•

Bring the burner back to full load;

check the combustion values.

• If the measurement values have

changed through the adjustment of

screw D on the SKP regulator or

screw N on the MBVEF valve, the

ratio R on the SKP regulator, or ratio

V on the MBVEF valve must be

adjusted in the desired direction.

m

Dimension Y of the burner head

setting may not be changed.

• If the burner head setting (dimension Y)

is changed, the entire adjustment

procedure for oil operation must be

repeated.

•

Limit switch I may no longer be

changed, as the 3 stage oil has

already been adjusted.

Setting the ignition load

•

Set the ignition load for gas

operation with cam III so that a safe

burner start is guaranteed. Here, the

ignition load can be set above or

below the low load value.

Setting the gas pressure switch

•

Set the switch to the minimum input

pressure.

•

Slowly close the gas shut-off valve.

•

The burner should switch off

because of lack of gas pressure.

•

Re-open the gas shut-off valve.

Setting the air pressure switch

•

Once the burner is again burning at

low load, determine the shut-off

point of the air pressure switch by

turning the scale disk.

•

Set the air pressure switch 10%

below this shut-off value.

Start-up

Regulating the system for gas operation

Setting the gas pressure switch, air pressure switch

Loading...

Loading...