45

i CAUTION

DO NOT MODIFY THE STRUCTURE OF

ANY SEAT. MODIFYING SEATS MAY

VOID MANUFACTURERS WARRANTIES,

RAISE LIABILITY ISSUES, AND

ENDANGER PASSENGERS.

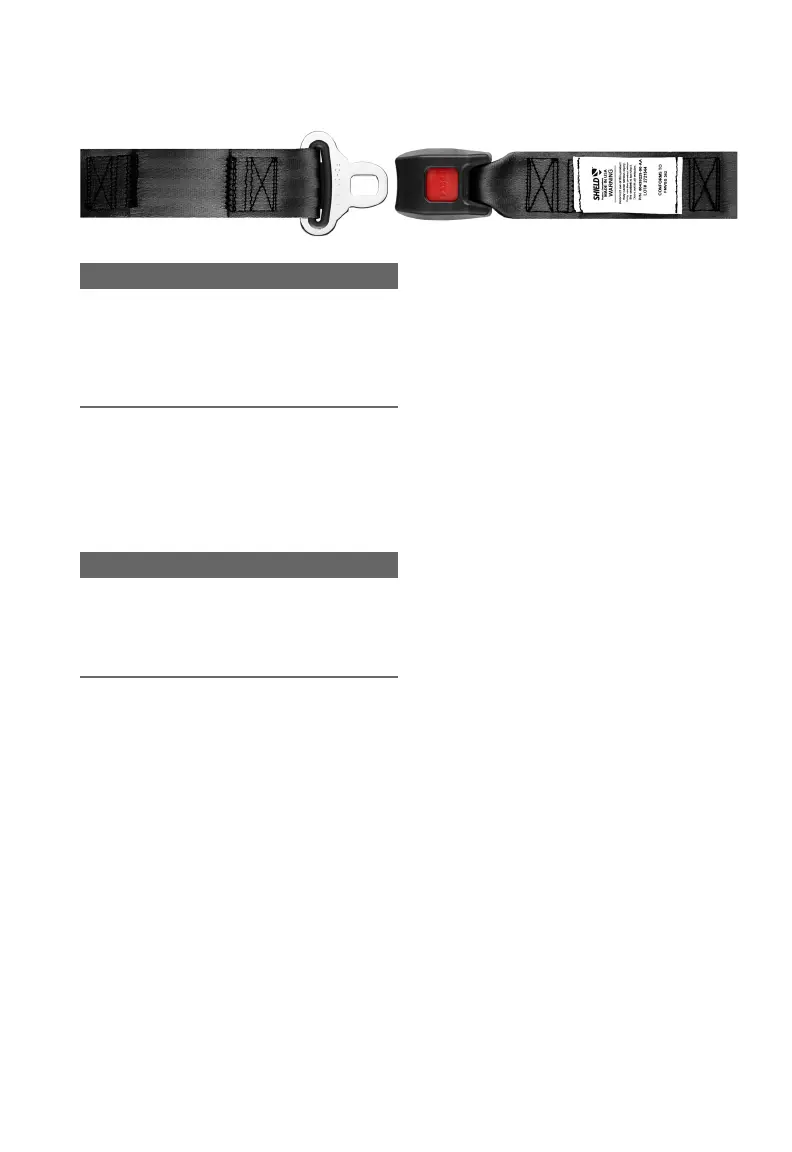

SEAT RESTRAINTS

We boast a wide variety of high-quality

standard and custom seating options,

however, because of the number of

seating alternatives, the types and

styles of your seat restraint will vary.

i CAUTION

MAKE SURE ALL BOLTS ARE

ENGAGED AND TORQUED TO THEIR

SPECIFICATIONS BEFORE ALLOWING

PASSENGERS TO OCCUPY THE SEATS.

SEATBELT MAINTENANCE

u

Inspect belts frequently to ensure

they are not cut, frayed, damaged or

contaminated by oils or chemicals.

u

Check each buckle to ensure proper

function.

Image: Seat Belt Connectors

05 SEATING

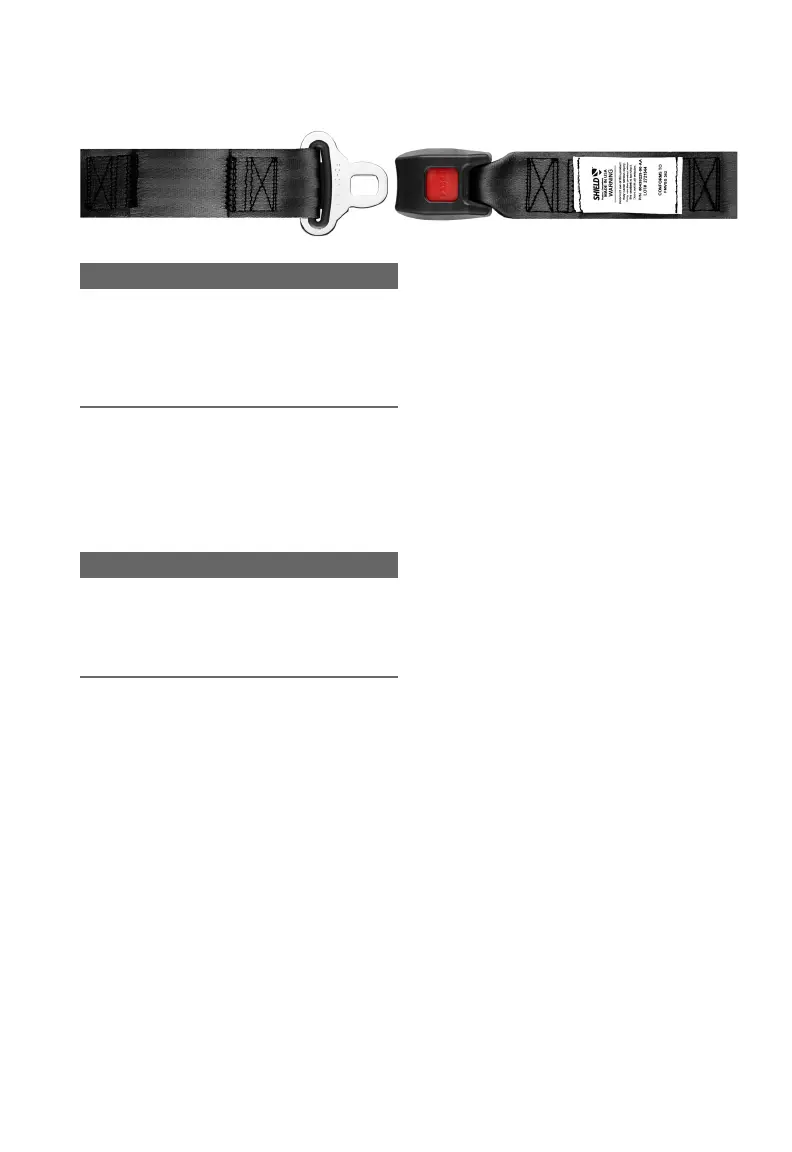

SECUREMENT SYSTEM

DAILY INSPECTION

CHECKLIST

u

Vehicle is equipped with a belt

cutter.

u

Check the retractors by pulling out

the webbing to ensure they are locking

properly.

u

Check to ensure webbing is not cut,

frayed, damaged or contaminated by

polishes, oils or chemicals.

u

Check that metal parts are not worn,

broken or cracked.

u

Check pin connector bushings to

ensure they are not cracked, broken or

missing.

u

Check that all mounting hardware,

such as nuts and bolts are secure.

u

Check floor anchorages to ensure

cleanliness and securement.

u

Check shoulder belt anchorages for

proper securement and operation.

u

Check lap and shoulder belt webbing

to ensure it is not cut, frayed, damaged

or contaminated with oils or chemicals.

u

Check buckles for damage and

ensure proper operation.

u

Check male buckle pin connector

bushing to ensure it is not cracked,

broken or missing.

u

Check any other parts of the

securement system and accessories

that may not be specifically indicated

in this checklist, but are pertinent to a

safe operational system.

Loading...

Loading...