84

13 MAINTENANCE CHECKLISTS

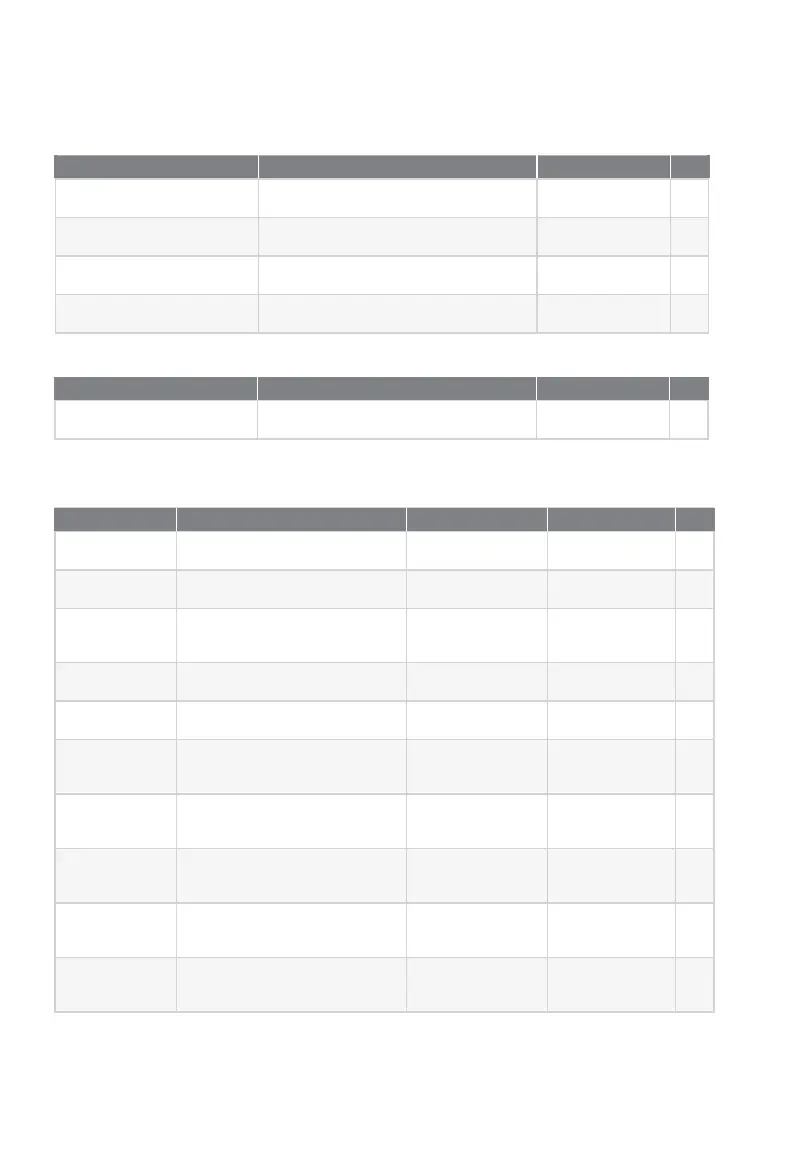

SEMI-ANNUAL MAINTENANCE CHECKLIST EVERY 6 MONTHS

ITEM MAINTENANCE AREA OF BUS

All Door Seals Apply a light coat of silicone to keep

rubber supple

Doors

All Window Seals Check for water intrusion, cracks and

sealing

Windows

Door Motor & Base Plate Check mounting bolts and adjusting screw

jam nuts for tightness

Doors

Door Opening & Closing Speed

(Air Doors Only)

Check for proper speed -

Adjust as necessary

Doors

ANNUAL MAINTENANCE CHECKLIST

ITEM MAINTENANCE AREA OF BUS

Wheelchair Lift Have dealer inspect & service. Change

pump oil.

Doors

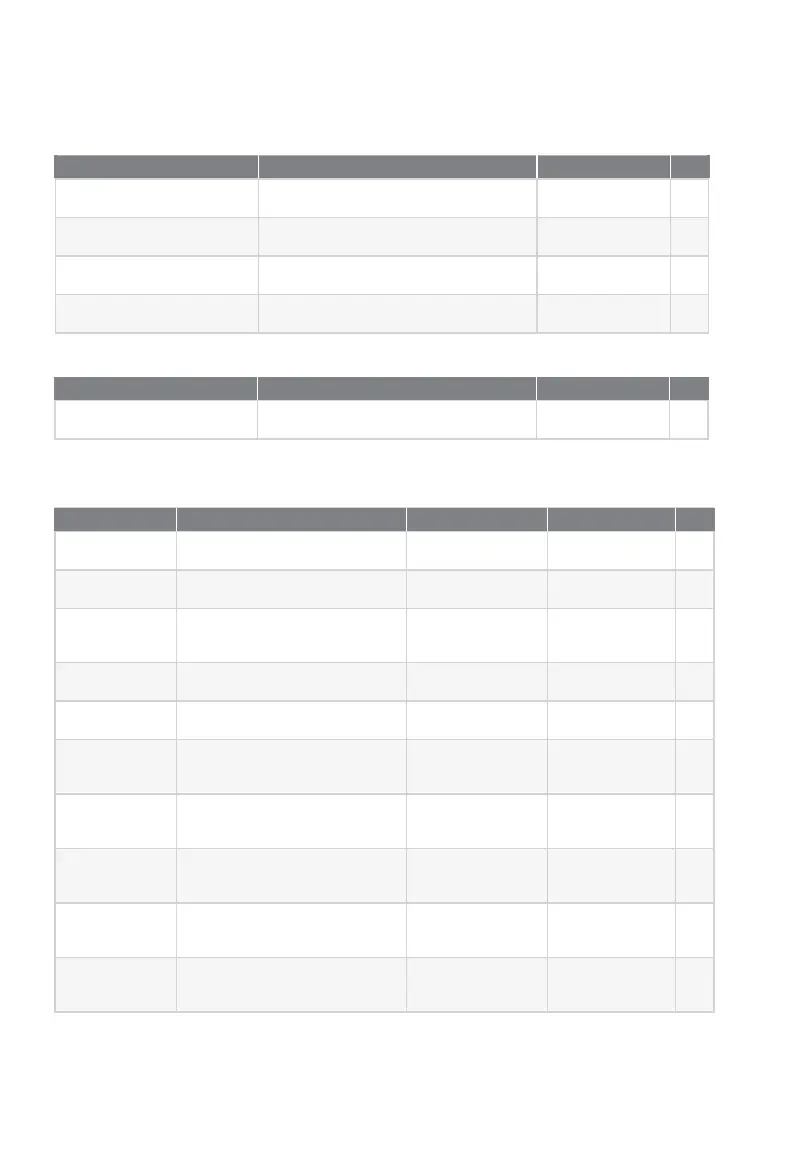

CYCLICAL MAINTENANCE CHECKLIST

ITEM MAINTENANCE AREA OF BUS

Passenger Entry

Door

Inspect for damage - lubricate

lower pins

Every 2,000 cycles Doors

Passenger Entry

Door

Check for damage and loose bolts

- Lubricate upper pins

Every 6,000 cycles Doors

Skirt-Mounted

Condenser

Inspect - Clean coil and fins with

jet of water - Straighten bent fins

when necessary

Every 100 operating

hours

Major

Options

Air Conditioning

Compressor

Check compressor drive belt

condition and tension

Every 100 operating

hours

Major

Options

Air Conditioning

Compressor

Check compressor cylinder under

load - Adjust if needed

Every 100 operating

hours

Major

Options

Air Conditioning

Compressor

Clutch Assembly

Check for signs of overheating or

slippage

Every 100 operating

hours

Major

Options

Air Conditioning

System, General

Inspect hoses, hose clamps, fan

and fan guard - Check belts and

fittings for tightness

Every 300 operating

hours

Major

Options

Air Conditioning

Refrigerant Level

Check refrigerant level at receiv-

ing tank sight glass - Check for

refrigerant oil leaks - Check charge

Every 600 operating

hours

Major

Options

Condenser Fan

Drive Motors

Inspect fan blades for damage and

proper clearance to shroud -

Inspect brushes for wear

Every 600 operating

hours

Major

Options

Evaporator Check air temperatures in and out

- Temperature drop should be

15° to 20° F

15° to 20° F.

Every 600 operating

hours

Major

Options

Loading...

Loading...