5.2 Analysis example

The analysis of steel and cast iron is generally carried out with approx. 500mg of sample

(normally grains or pieces) by adding 1,5 tungsten accelerator.

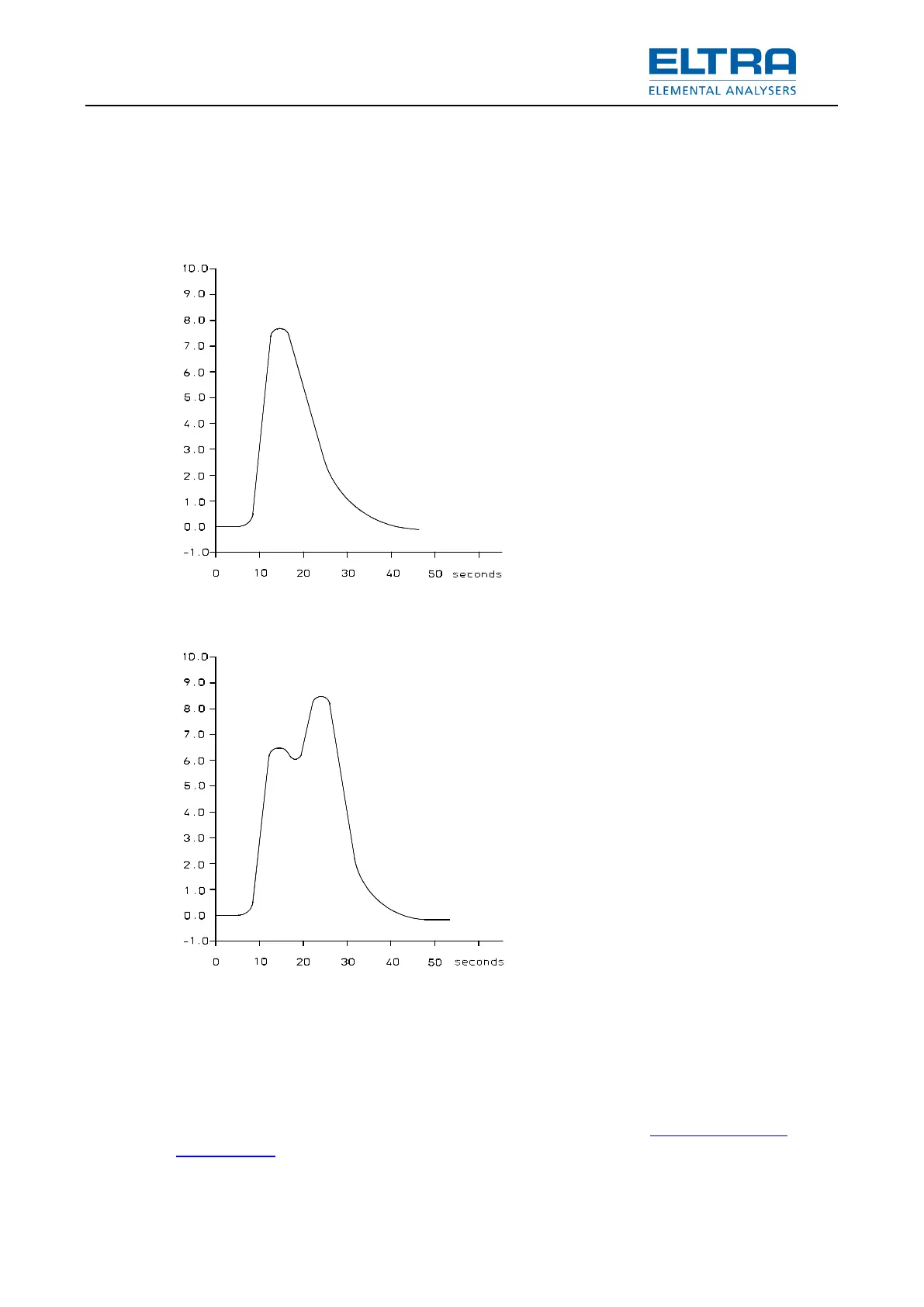

5.2.1 Combustion peak

The combustion is quite rapid and the peaks on the PC screen look as follows:

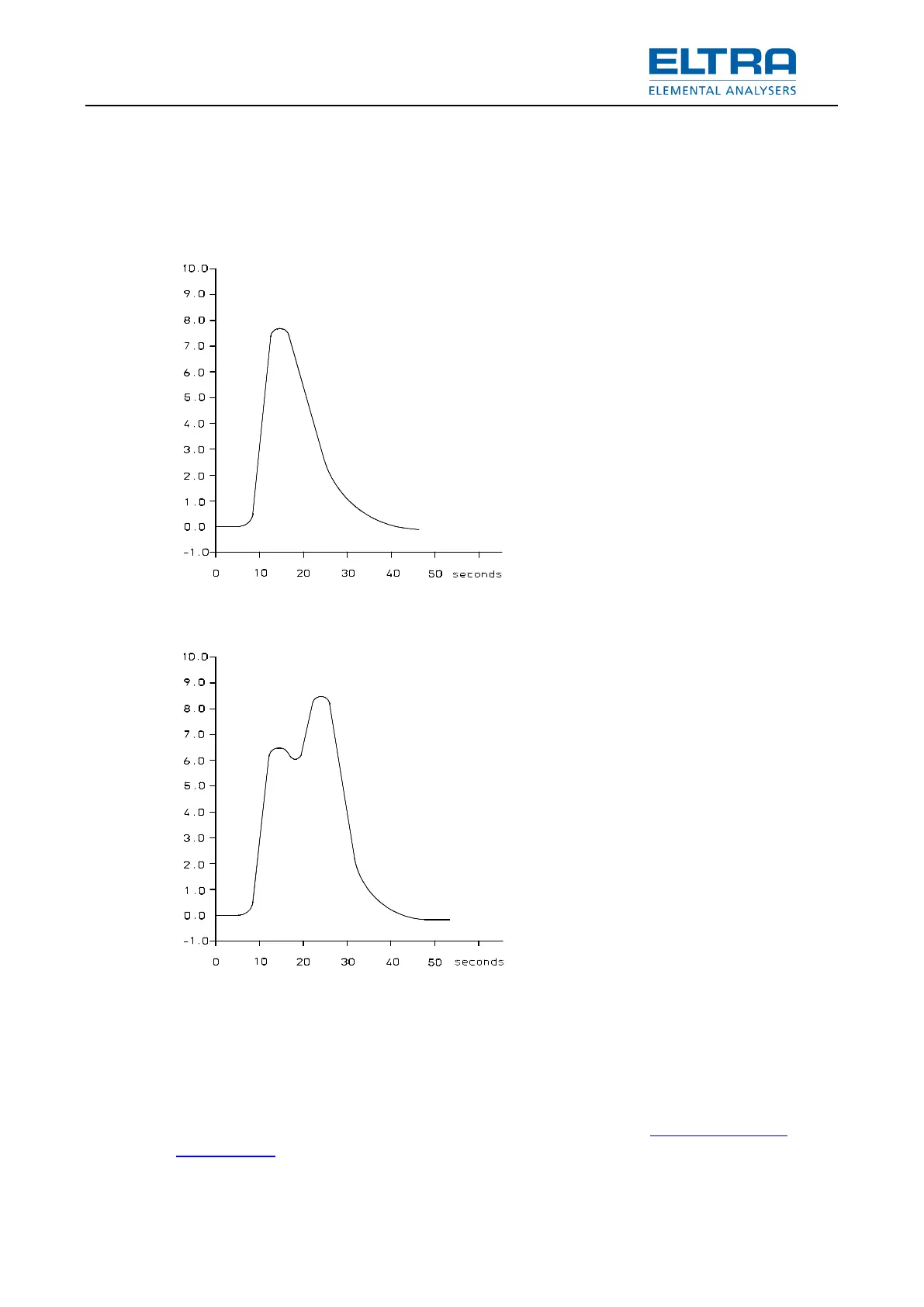

: Combustion double peak

The reason is that either the sample doesn't contain enough iron or the sample is made of metal

powder.

In this case take 2g tungsten instead of 1.5g. If the combustion still provides double peaks or

there is yellow dust on the inner surface of the crucible after the analysis, take 1g tungsten,

500mg pure Iron accelerator and 500mg sample.

In case of metal analysis the dust trap has to be cleaned and the moisture trap has to be

replaced every 100 analyses or at least every two days. See chapter General Information

(Maintenance)

The combustion tube doesn't need any cleaning by the operator, due to automatic cleaning after

each analysis.

Loading...

Loading...