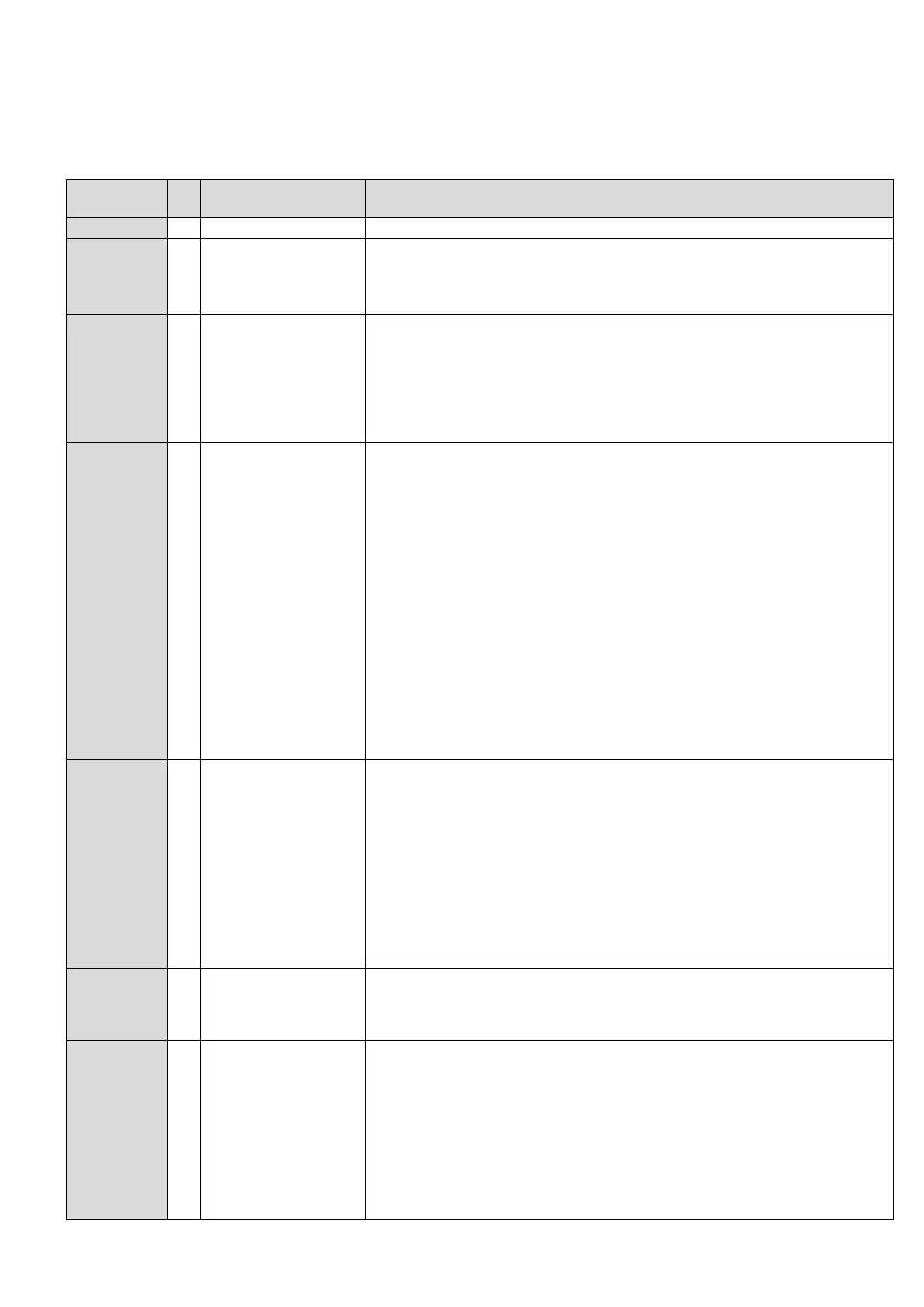

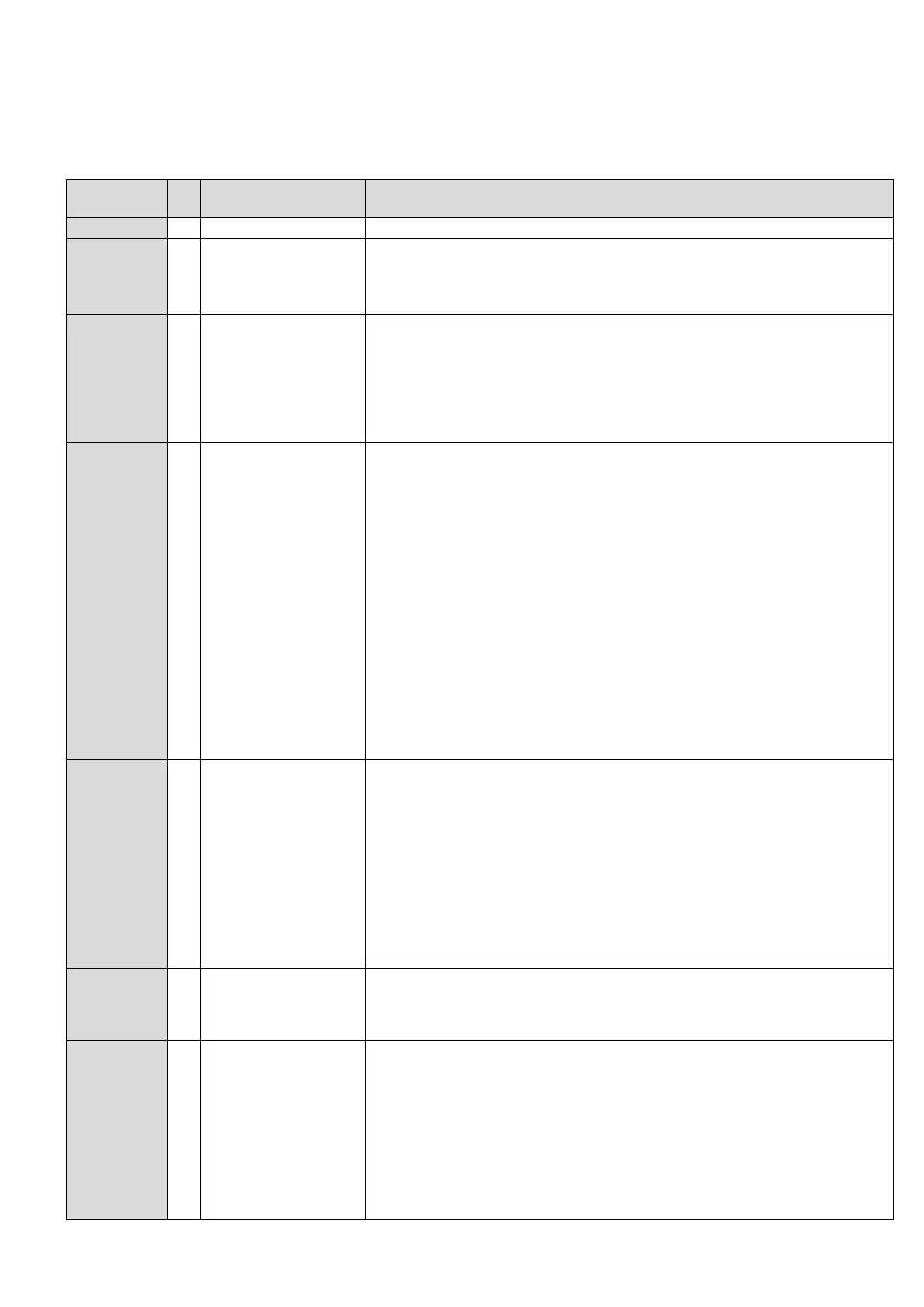

90 PACMotion VFD AC Variable Speed Drive User Guide GFK-3111A

Troubleshooting

Fault Messages

Table 65: Derating for Ambient Temperature

Fault Code

No.

OLED Message

Description

Corrective Action

No fault 00 No Fault Displayed in P0-13 if no faults are recorded in the log.

Brake over

current

01 Brake channel over

current

Ensure the connected brake resistor is above the minimum permissible level

for the drive – refer to the ratings shown in section Input/Output Power and

Current Ratings on page 84.

Check the brake resistor and wiring for possible short circuits.

Brake resistor

overload

02 Brake resistor overload The drive software has determined that the brake resistor is overloaded, and

trips to protect the resistor. Always ensure the brake resistor is being operated

within its designed parameter before making any parameter or system

changes.

To reduce the load on the resistor, increase the deceleration time, reduce the

load inertia or add further brake resistors in parallel, observing the minimum

resistance value for the drive in use.

Over current 03 Over current trip Fault Occurs on Drive Enable

Check the motor and motor connection cable for phase – phase and phase –

earth short circuits.

Check the load mechanically for a jam, blockage or stalled condition.

Ensure the motor nameplate parameters are correctly entered, P1-07, P1-08,

P1-09.

If operating in Vector mode (P4-01 – 0 or 1), also check the motor power

factor in P4-05 and ensure an autotune has been successfully completed for

the connected motor.

Reduced the Boost voltage setting in P1-11.

Increase the ramp up time in P1-03.

If the connected motor has a holding brake, ensure the brake is correctly

connected and controlled, and is releasing correctly.

Fault Occurs When Running

If operating in Vector mode (P4-01 – 0 or 1), reduce the speed loop gain in

P4-03.

Motor

thermal

overload

04 Drive has tripped

on overload after

delivering >100% of

value in P1-08 for a

period of time

Check to see when the decimal points are ashing (drive in overload) and

either increase acceleration rate or reduce the load.

Check motor cable length is within the limit specied for the relevant drive in

section 10.2.

Ensure the motor nameplate parameters are correctly entered in P1-07, P1-08,

and P1-09.

If operating in Vector mode (P4-01 – 0 or 1), also check the motor power

factor in P4-05 and ensure an autotune has been successfully completed for

the connected motor.

Check the load mechanically to ensure it is free, and that no jams, blockages or

other mechanical faults exist.

Power stage

trip

05 Hardware Over Current Check the wiring to motor and the motor for phase to phase and phase to

earth short circuits. Disconnect the motor and motor cable and retest. If the

drive trips with no motor connected, it must be replaced and the system fully

checked and retested before a replacement unit is installed.

Over voltage 06 Over voltage on DC bus The value of the DC Bus Voltage can be displayed in P0-20.

A historical log is stored at 256 ms intervals prior to a trip in parameter P0-36.

This fault is generally caused by excessive regenerative energy being

transferred from the load back to the drive. When a high inertia or over hauling

type load is connected.

If the fault occurs on stopping or during deceleration, increase the

deceleration ramp time P1-04 or connect a suitable brake resistor to the drive.

If operating in Vector Mode, reduce the speed loop gain P4-03.

If operating in PID control, ensure that ramps are active by reducing P3-11.

Loading...

Loading...