30

Reference Manual

00809-0100-4772, Rev FA

Installation

March 2016

Installation

Note

A grounding strap is specifically required if using the transient protection terminal block

(Option Code T1). Always ground the meter per the local electrical code.

3.5.4 Flange bolts

Install the flowmeter between two conventional pipe flanges, as shown in Figure 3-12 and

Figure 3-13 on page 33. Figure 3-6, Figure 3-2, and Figure 3-3 list the recommended

minimum stud bolt lengths for wafer-style meter body size and different flange ratings.

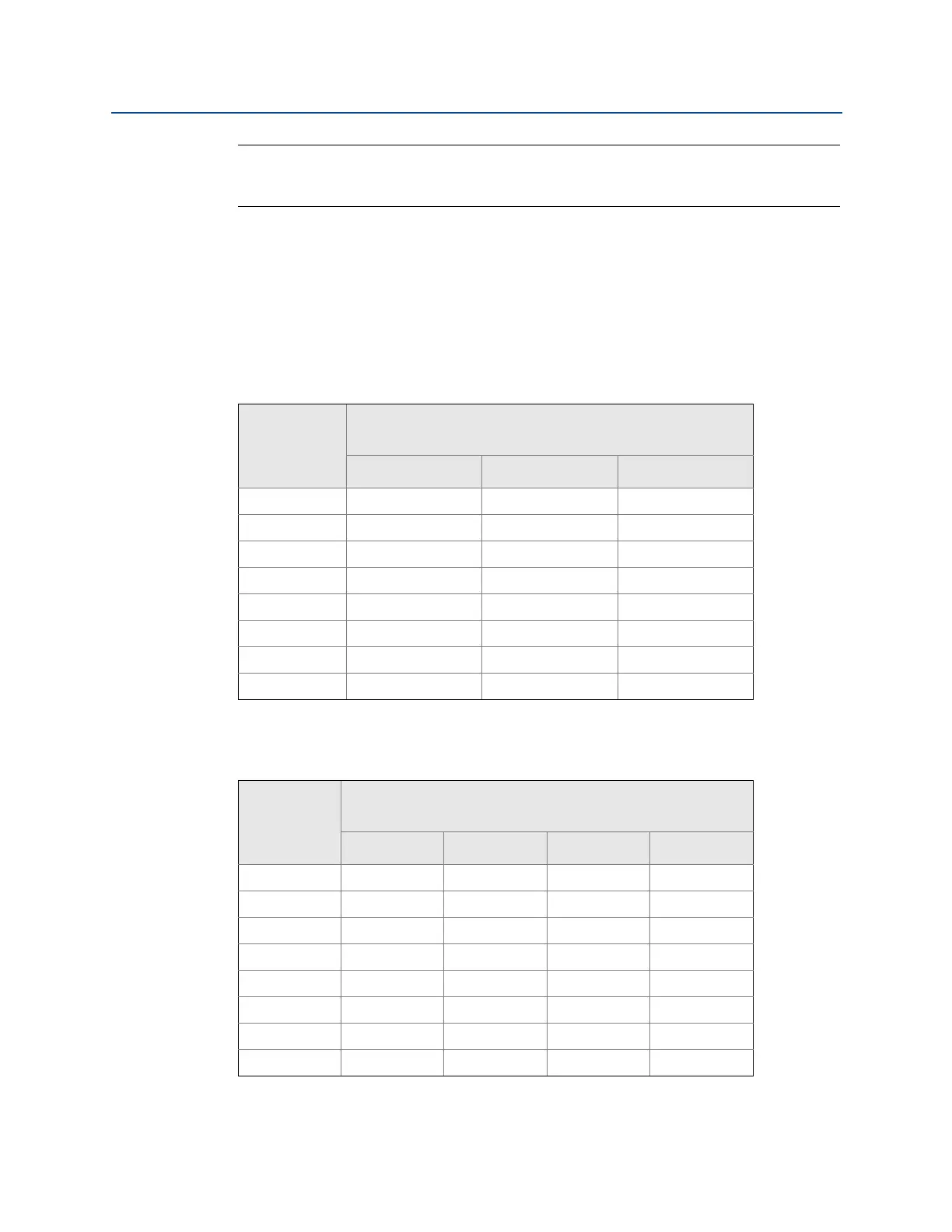

Table 3-1. Minimum Recommended Stud Bolt Lengths for Wafer Installation with

ASME B16.5 (ANSI) Flanges

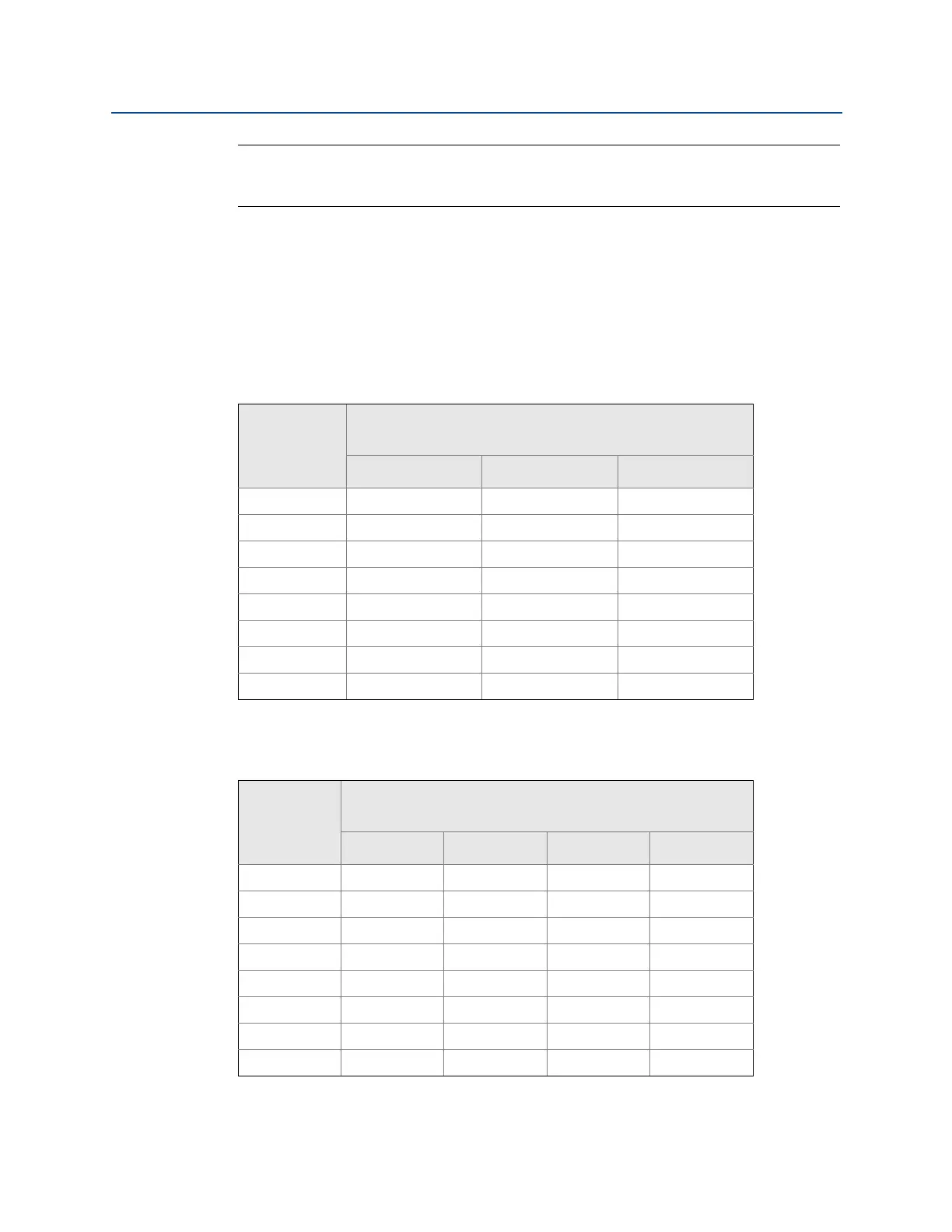

Table 3-2. Minimum Recommended Stud Bolt Lengths for Wafer Installation with DIN

Flanges

Line size

Minimum recommended stud bolt lengths

(in Inches) for each flange rating

Class 150 Class 300 Class 600

½-inch 6.00 6.25 6.25

1-inch 6.25 7.00 7.50

1½-inch 7.25 8.50 9.00

2-inch 8.50 8.75 9.50

3-inch 9.00 10.00 10.50

4-inch 9.50 10.75 12.25

6-inch 10.75 11.50 14.00

8-inch 12.75 14.50 16.75

Line size

Minimum recommended stud bolt lengths

(in mm) for each flange rating

PN 16 PN 40 PN 64 PN 100

DN 15 160 160 170 170

DN 25 160 160 200 200

DN 40 200 200 230 230

DN 50 220 220 250 270

DN 80 230 230 260 280

DN 100 240 260 290 310

DN 150 270 300 330 350

DN 200 320 360 400 420

Loading...

Loading...