40 Installation CG Drives & Automation 01-7491-01r0

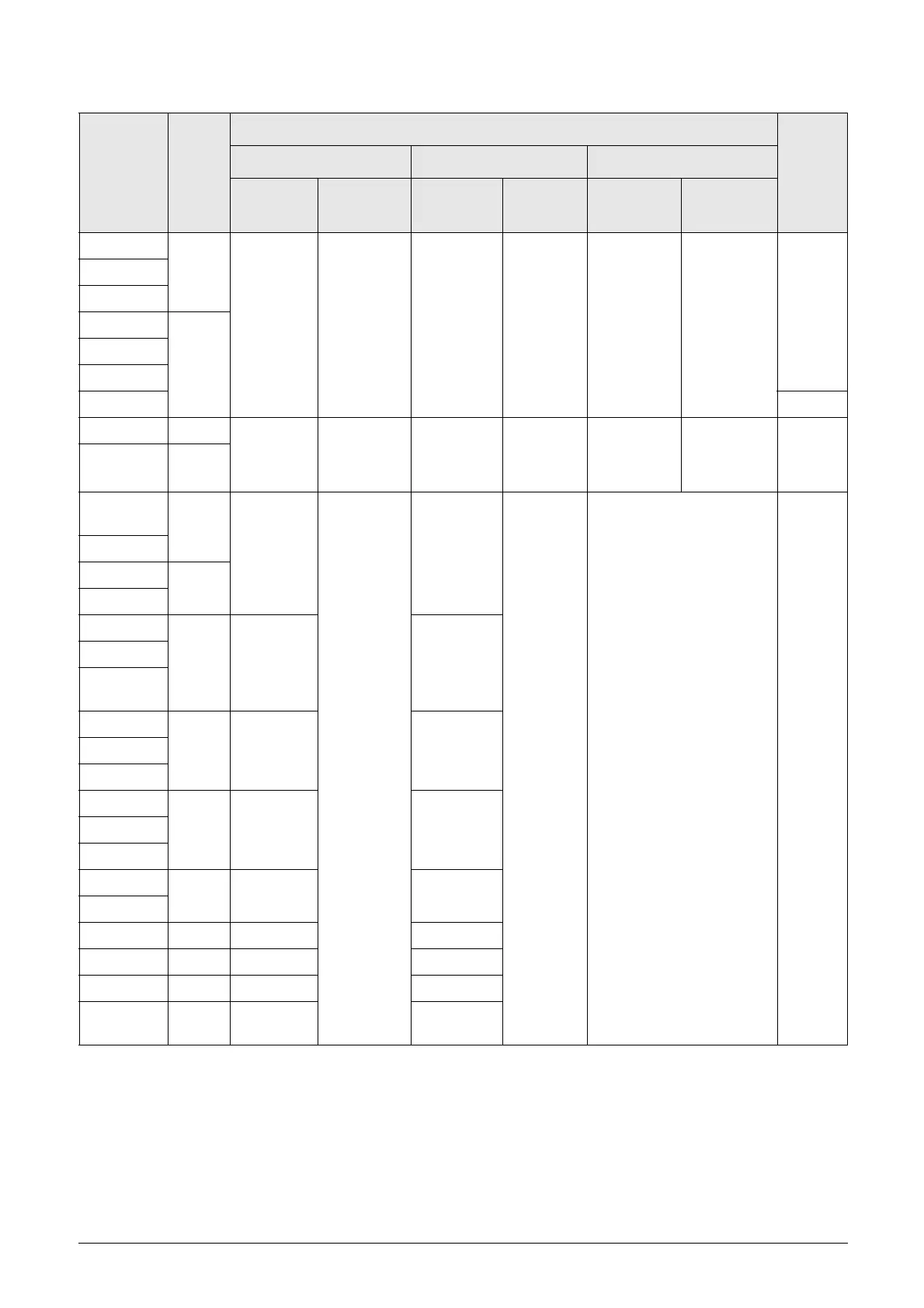

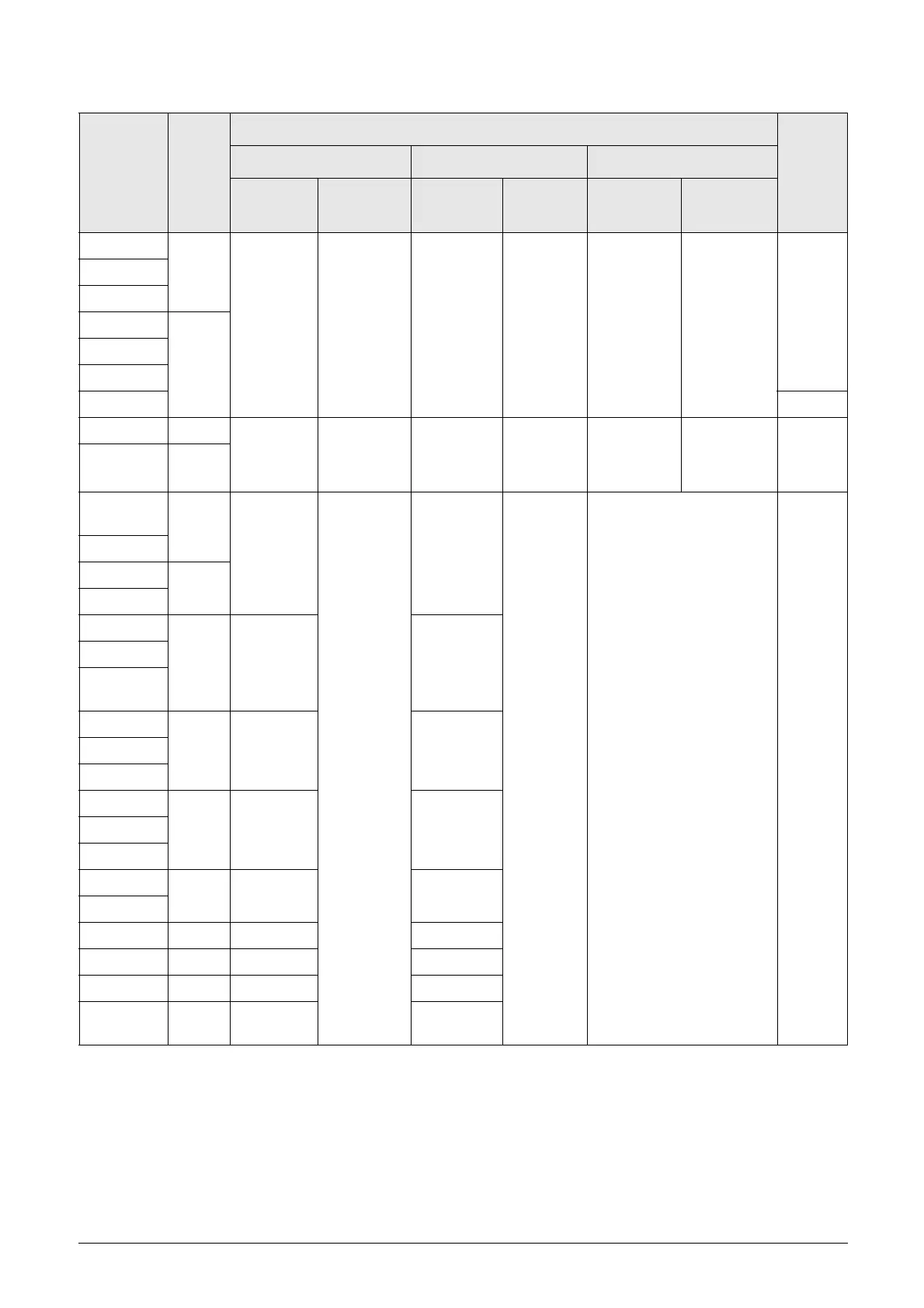

* With cable lug for M6 screw.

** Valid when brake chopper electronics are built in.

*** Use 90 °C Mains and motor cables if surrounding temperature is higher than 35 °C otherwise 75 °C cables.

**** IP 23 or IP 54 for cabinet drive.

***** Cable lug tightening torque = 20 Nm, when terminal lug removed.

48-205-20

F2

25 - 240

31 (for

25-34 mm

2

)

42 (for

35-152 mm

2

)

56 (for

153-240

mm

2

)

*****

16 - 150

31 (for

16-34 mm

2

)

42 (for

35-150

mm

2

)

*****

25 - 240

16 - 185 **

31 (for

25-34 mm

2

)

42 (for

35-152 mm

2

)

56 (for

153-240 mm

2

)

10 **

Copper

(Cu) /

Aluminum

(Al) 75°C

48-244-20

48-293-20

48-210-54

F

48-228-54

48-250-54

48-295-54

***

48-365-20 FA2

M10

connection

47

M8

connection

24

M8

connection

24

Copper

(Cu) /

Aluminum

(Al) 75°C

48-365-54 FA

48-300-

IP

****

G

(2x) 25 - 240

31 (for

25-34 mm

2

)

42 (for

35-152 mm

2

)

56 (for

153-240

mm

2

)

(2x) 25 - 240

31 (for

25-34 mm

2

)

42 (for

35-152

mm

2

)

56 (for

153-240

mm

2

)

PE/Earth via mounting screws/

mounting frame.

In order to secure proper

earthing, always use all

mounting screws and tighten

them thoroughly.

Copper

(Cu) /

Aluminum

(Al) 75°C

48-375-IP

48-430-IP

H

48-500-IP

48-600-IP

I (3x) 25 - 240 (3x) 25 - 240

48-650-IP

48-720, 750-

IP

48-860-IP

J (4x) 25 - 240 (4x) 25 - 24048-900-IP

48-1k0-IP

48-1k15-IP

KA (5x) 25 - 240 (5x) 25 - 24048-1k2-IP

48-1k25-IP

48-1k35-IP

K (6x) 25 - 240 (6x) 25 - 240

48-1k5-IP

48-1k75-IP L (7x) 25 - 240 (7x) 25 - 240

48-2k0-IP M (8x) 25 - 240 (8x) 25 - 240

48-2k25-IP N (9x) 25 - 240 (9x) 25 - 240

48-2k5-IP O

(10x) 25 -

240

(10x) 25 - 240

Table 18 Cable connector range and tightening torque for Emotron FDU48 and FDU52, according to IEC ratings.

Model FDU

Frame

size

Cable cross section connector range

Cable

type

Mains and motor Brake PE

Cable area

mm

2

Tightening

torque

Nm

Cable area

mm

2

Tightening

torque

Nm

Cable area

mm

2

Tightening

torque

Nm

Loading...

Loading...