Cerabar PMP21 IO-Link System integration

Endress+Hauser 25

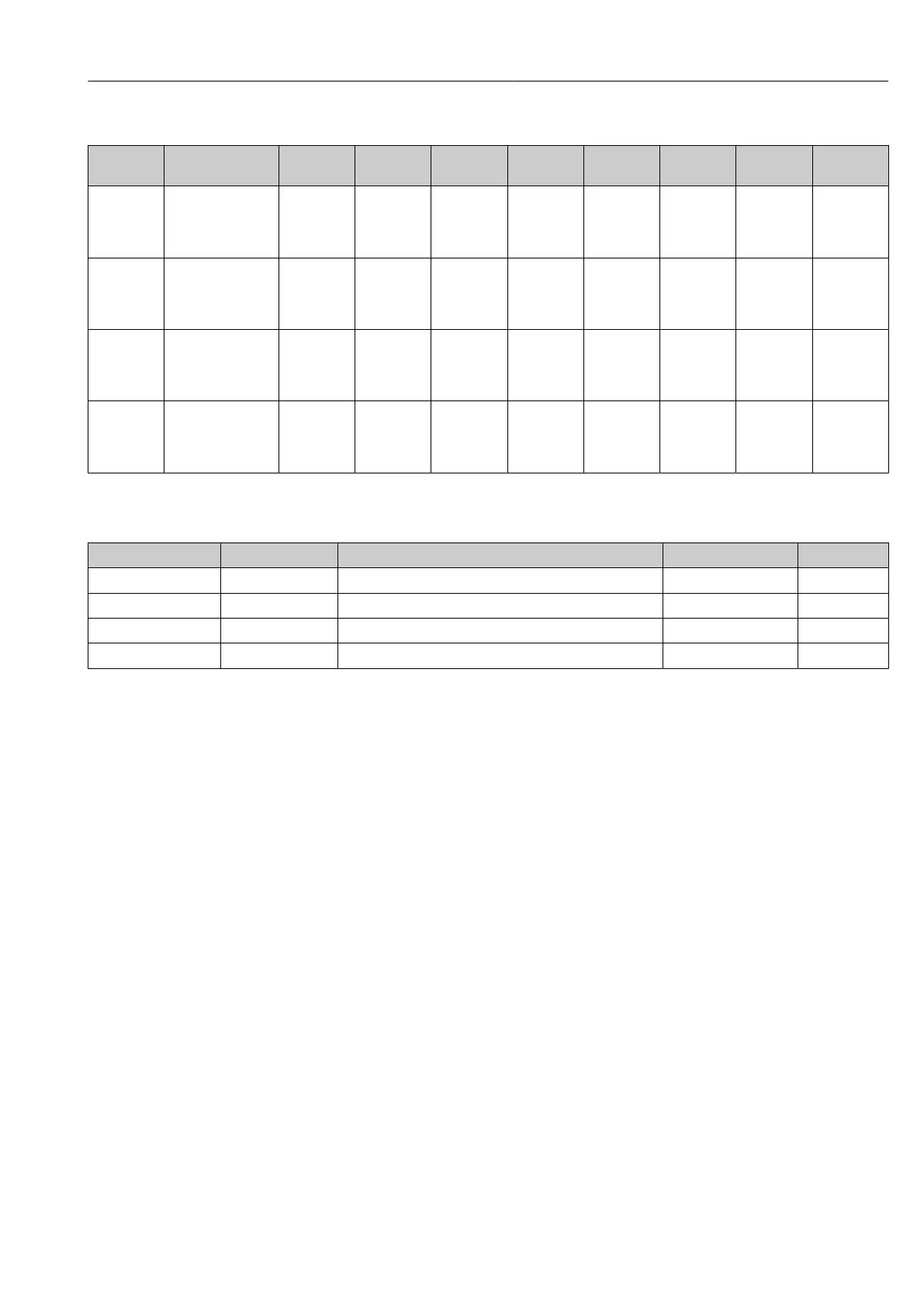

Measurement Data Information

ISDU (dec) Subindex Description ISDU (hex) Size (byte) Data type Access Default

value

Value

range

Data

storage

16512 1 MDC

Descriptor -

Pressure.Lo

wer Value

0x4080 4 Float32T r 0 - No

16512 2 MDC

Descriptor -

Pressure.Up

per Value

0x4080 4 Float32T r 0 - No

16512 3 MDC

Descriptor -

Pressure.Un

it Code

0x4080 2 UintegerT r 1130 (Pa) - No

16512 4 MDC

Descriptor -

Pressure.Sca

le

0x4080 1 IntegerT r 0 - No

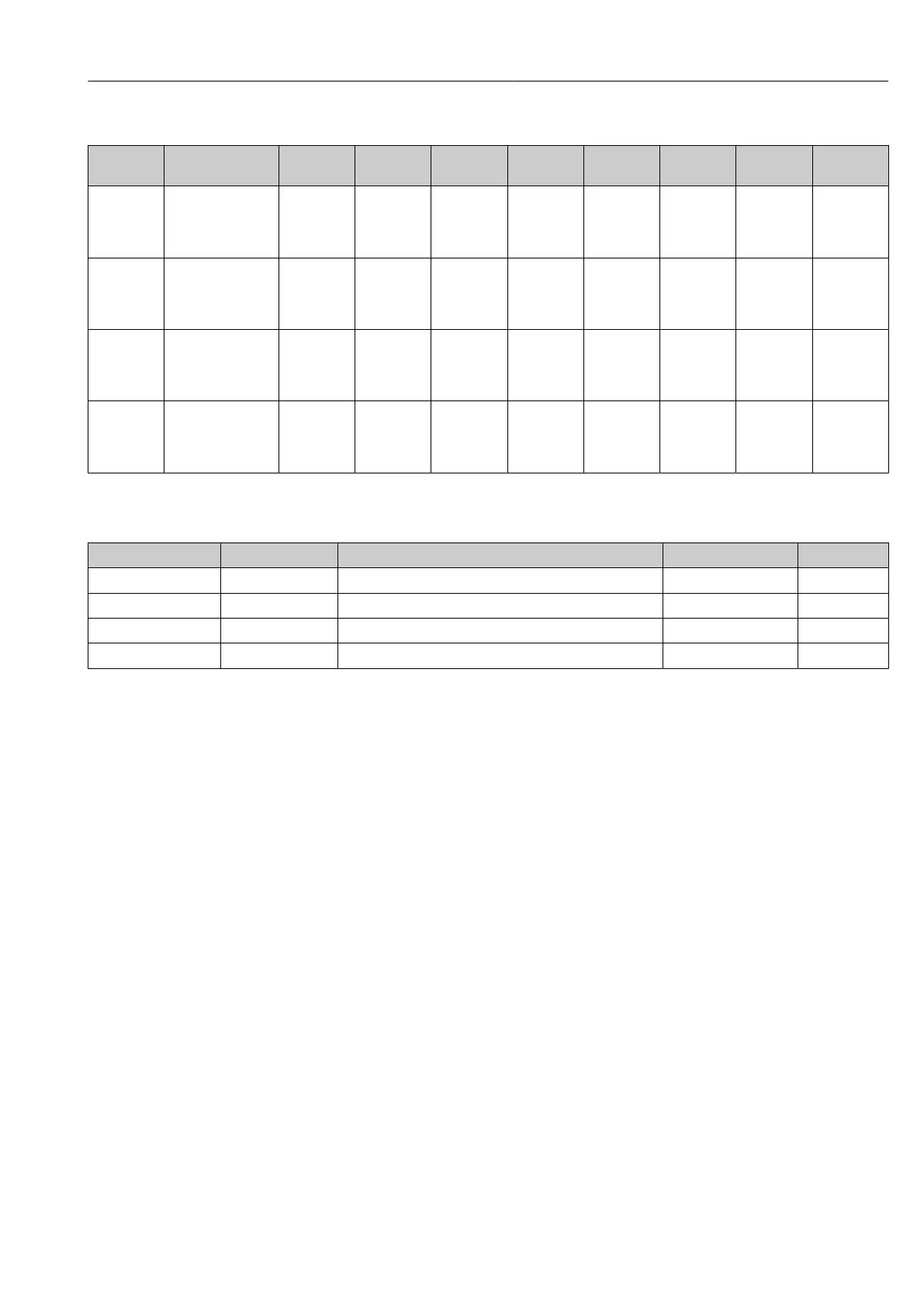

8.2.3 System commands

ISDU (dec) Subindex Description ISDU (hex) Access

2 65 Teach SP1 0x0002 w

2 66 Teach SP2 0x0002 w

2 130 Reset to factory settings (RES) 0x0002 w

2 131 Back-To-Box 0x0002 w

8.2.4 Switching signals

The switching signals offer a simple way of monitoring the measured values for limit

violations.

Each switching signal is clearly assigned to a process value and provides a status. This

status is transmitted with the process data (process data link). Its switching behavior must

be configured using the configuration parameters of a "Switching Signal Channel" (SSC). In

addition to manual configuration for switch points SP1 and SP2, a teach mechanism is

available in the "Teach" menu. This mechanism writes the current process value to the

selected SSC via a system command. The following section illustrates the different

behaviors of the modes available for selection. The "Logic" parameter is always "High active"

in these cases. If the logic is supposed to be inverted, the "Logic" parameter can be set to

"Low active"(→ 33).

Single Point Mode

SP2 is not used in this mode.

Loading...

Loading...