Installation Cerabar M, Deltabar M, Deltapilot M / 4...20 mA HART

12 Endress+Hauser

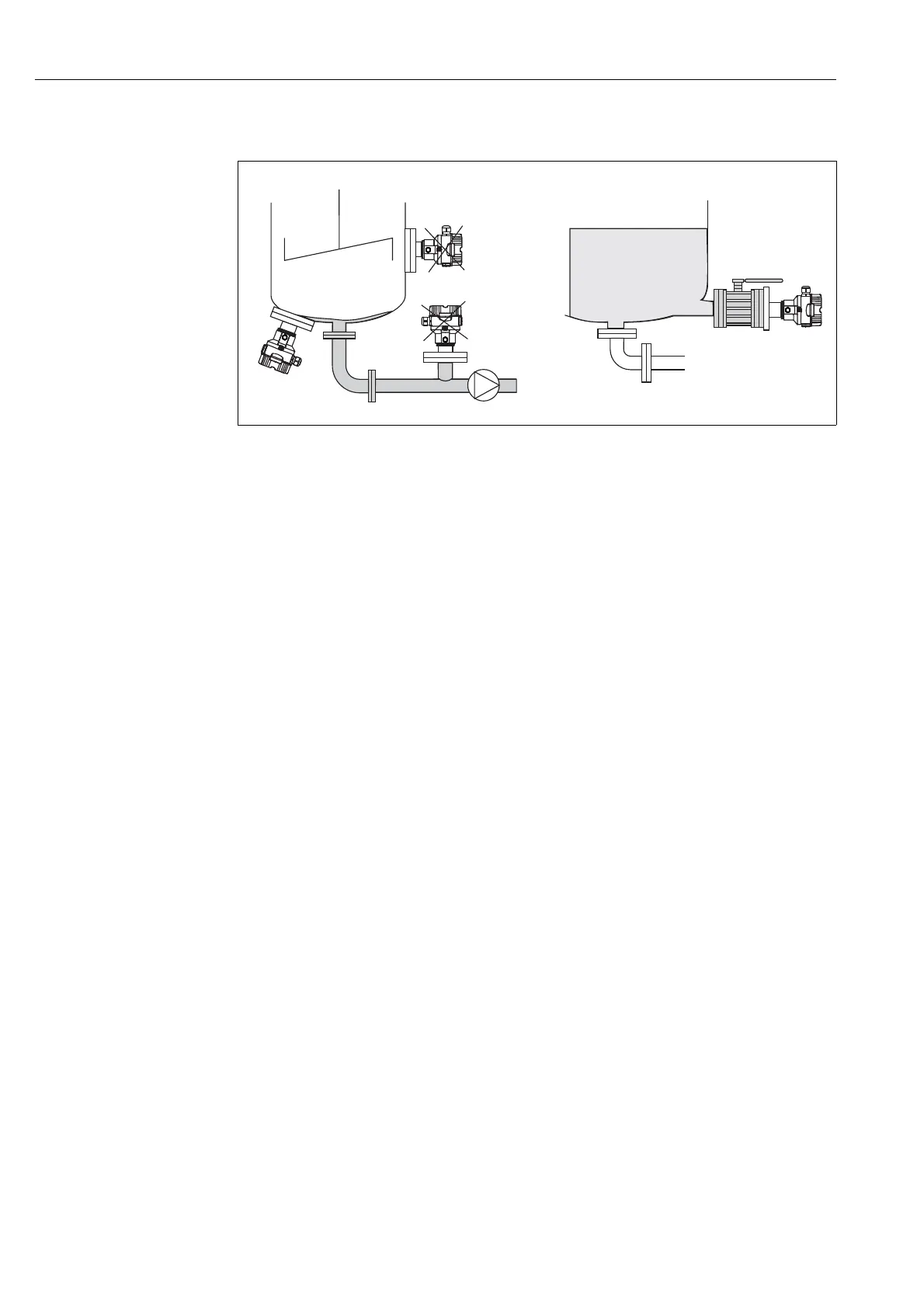

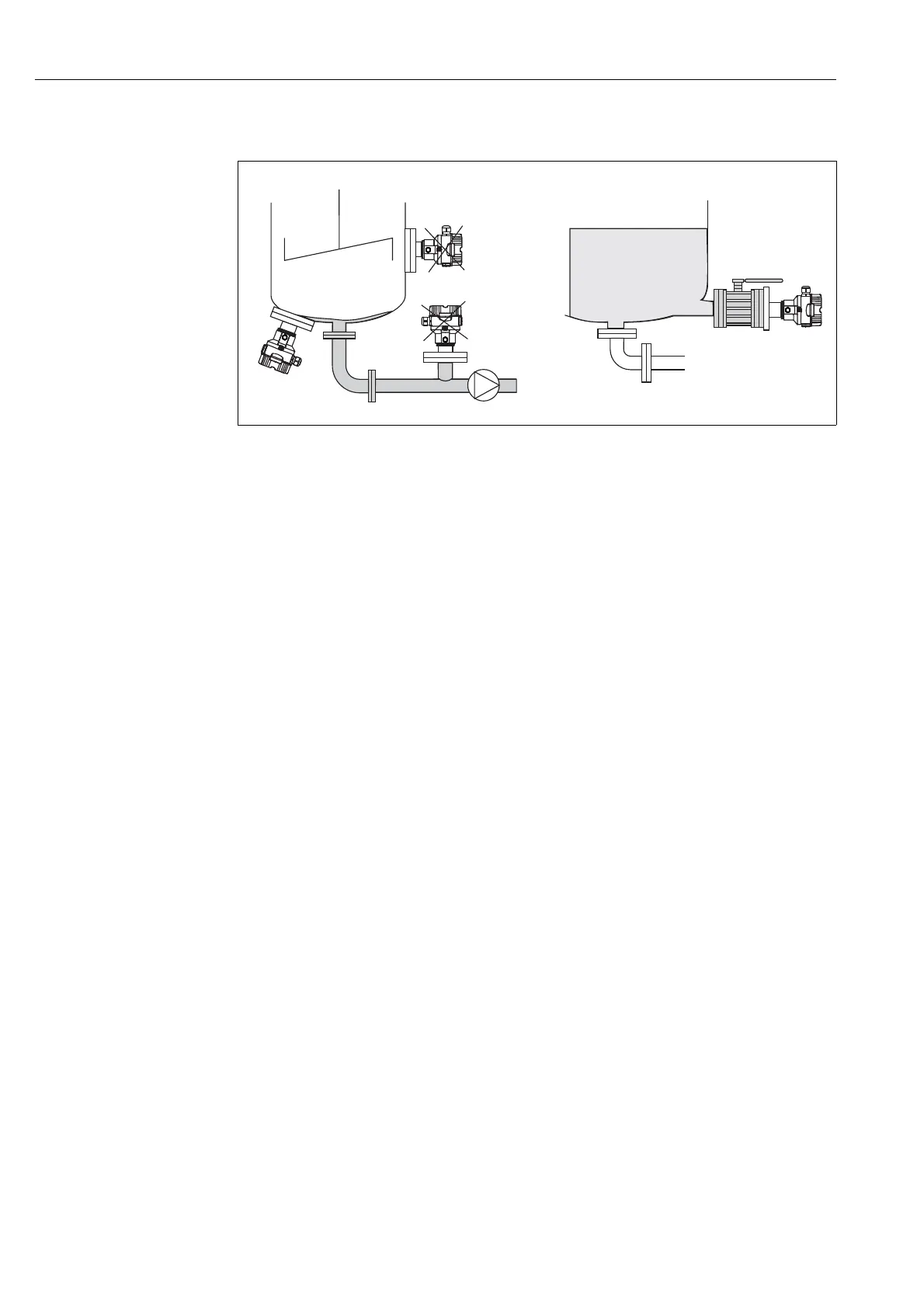

Level measurement

P01-xMx5xxxx-11-xx-xx-xx-000

Fig. 8: Measuring arrangement for level

• Always install the Cerabar M below the lowest measuring point.

• Do not mount the device in the filling curtain or at a point in the tank which could be affected by

pressure pulses from an agitator.

• Do not mount the device in the suction area of a pump.

• The calibration and functional test can be carried out more easily if you mount the device

downstream of a shutoff device.

PVDF interchangeable threaded boss

!

Note!

A maximum torque of 7 Nm (5.16 lbs ft) is permitted for devices with a PVDF interchangeable

threaded boss. The thread connection may become loose at high temperatures and pressures. This

means that the integrity of the thread must be checked regularly and may need to be tightened using

the torque given above. Teflon tape is recommended for sealing the 1/2 NPT thread.

3.3.2 Installation instructions for devices with diaphragm seals –

PMP55

!

Note!

• Cerabar M devices with diaphragm seals are screwed in, flanged or clamped, depending on the

type of diaphragm seal.

• A diaphragm seal and the pressure transmitter together form a closed, oil-filled calibrated system.

The fill fluid hole is sealed and may not be opened.

• Do not clean or touch the process isolating diaphragm of the diaphragm seal with hard or pointed

objects.

• Do not remove process isolating diaphragm protection until shortly before installation.

• When using a mounting bracket, sufficient strain relief must be ensured for the capillaries in order

to prevent the capillary bending down (bending radius 100 mm (3.94 in)).

• Please note that the hydrostatic pressure of the liquid columns in the capillaries can cause zero

point shift. The zero point shift can be corrected. ä 56, Section 6.4 "Position zero

adjustment".

• Please observe the application limits of the diaphragm seal filling oil as detailed in the Technical

Information for Cerabar M TI00436P, "Planning instructions for diaphragm seal systems" section.

In order to obtain more precise measurement results and to avoid a defect in the device, mount the

capillaries as follows:

• Vibration-free (in order to avoid additional pressure fluctuations)

• Not in the vicinity of heating or cooling lines

• Insulate if the ambient temperature is below or above the reference temperature

• With a bending radius of 100 mm (3.94 in).

Loading...

Loading...