Why is my Endress+Hauser Liquiline CM44P display dark?

- MMichael AllenAug 20, 2025

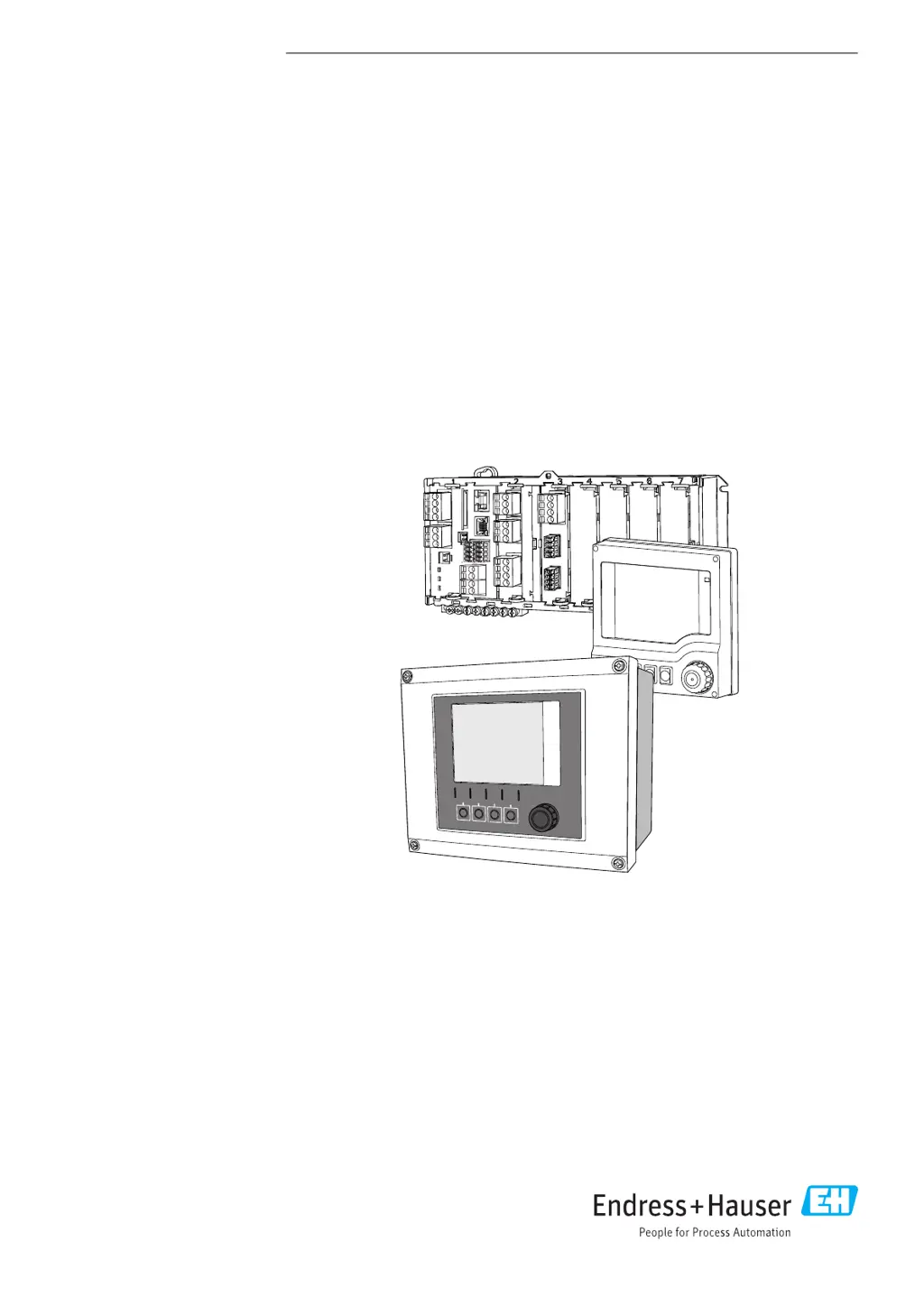

A dark display on your Endress+Hauser Controller can be due to several reasons: a lack of supply voltage (check if supply voltage is applied), the display connector being plugged in incorrectly (it must be in the RJ45 socket on the base module), or a defective base module (replace the base module).