5 Operation

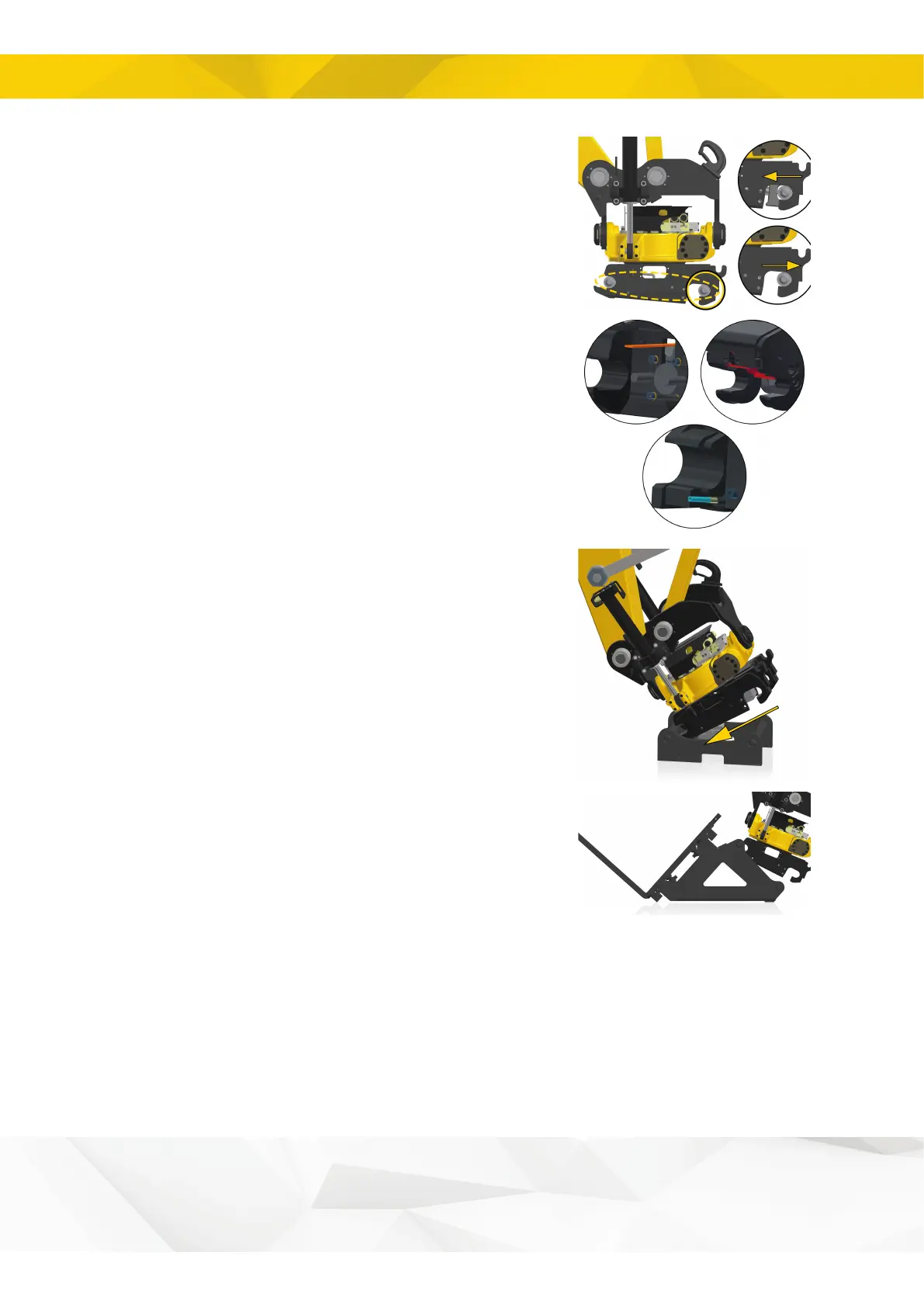

2. Activate the hydraulics to operate the locking bolts.

HS/SW with sensor: The sound and light warning

signals are activated when the locking cylinder is in the

open position.

3. Check that the indicator rod is out. Indicator rod

location may vary depending on the tiltrotator model.

ECPUP: Check that the red hook is in the open position.

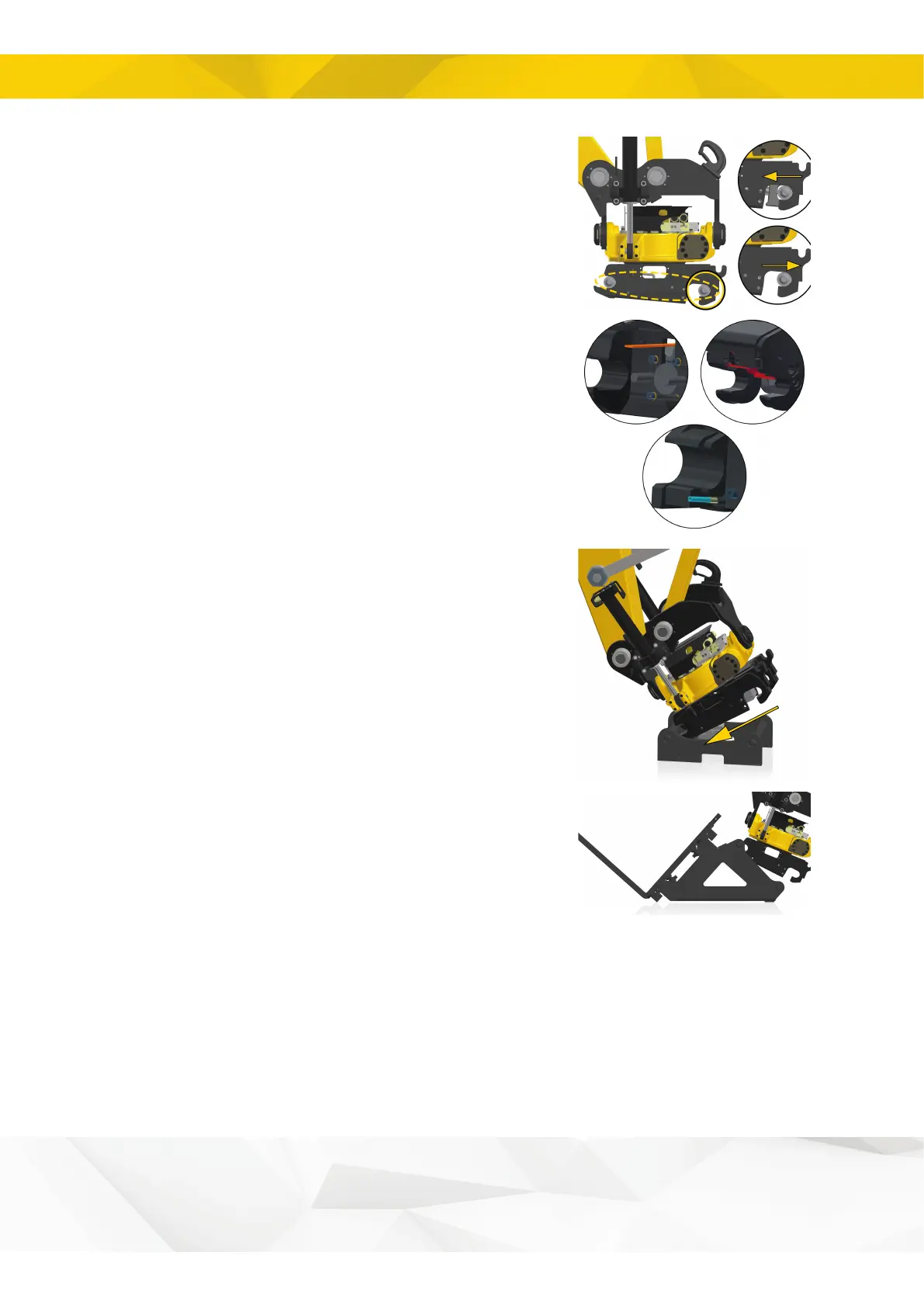

4. Move the quick coupler towards the tool.

EC-Oil: Make sure the tool is positioned such that the

shaft with the EC-Oil block is located closest to the base

machine. If the tool is positioned correctly, the block will

be visible on the left side of the shaft as seen from the

cab.

Pallet fork: To avoid overload when connecting, the

quick coupler locking pins must face away from the forklift

tines.

28

Loading...

Loading...