6 Maintenance

6.5. Service every 250 operating hours

Check is performed by operator. Make entry in service record; see 11.2. Service record.

- Review points according to section 6.2. Daily inspections.

- Shimming, tilt upper section.

- Visual inspection of bushings and spherical bearings; see section 10.3. Tiltrotator

overview.

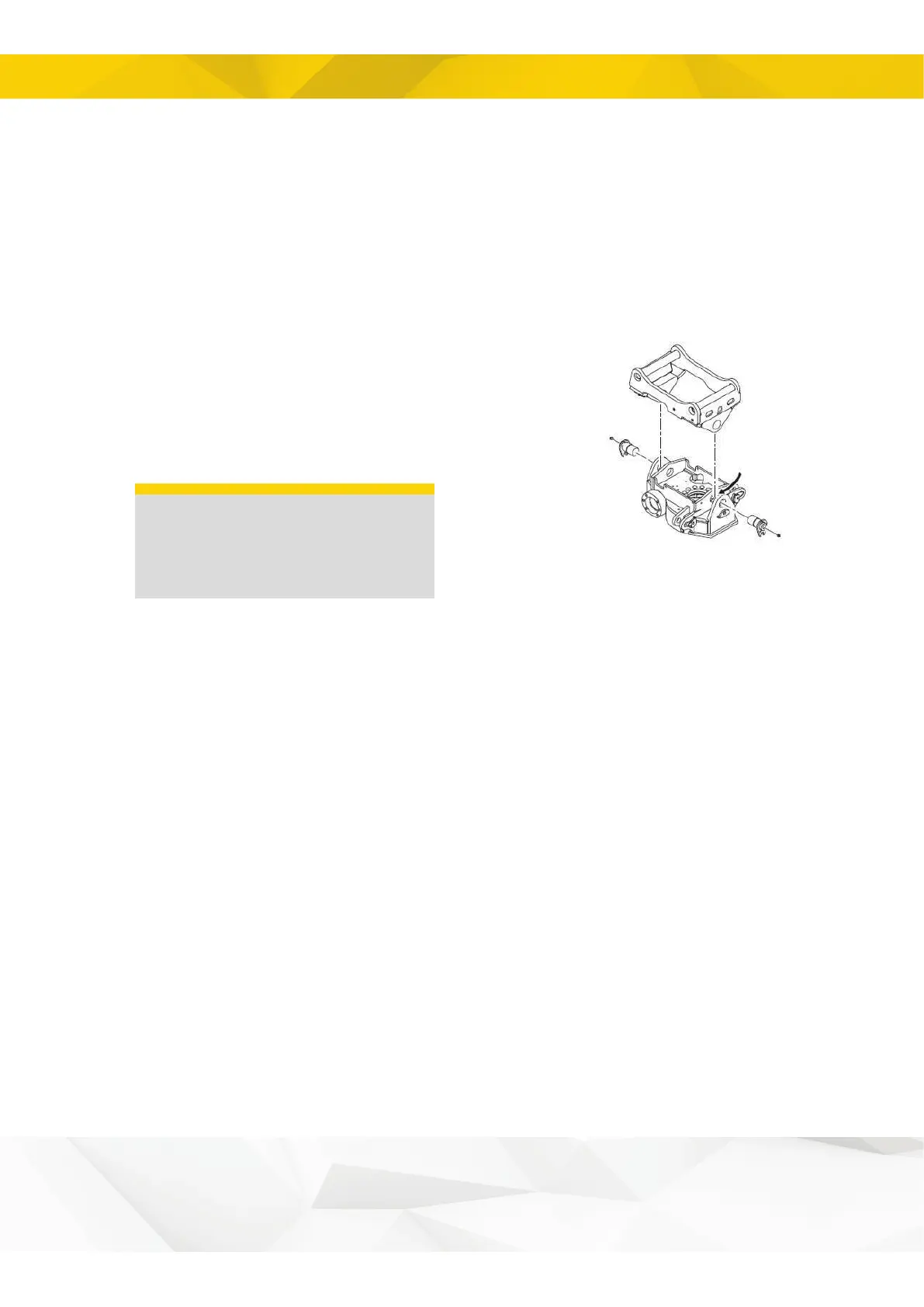

6.5.1. Shimming, tilt upper section

1. Lightly oil the bushings for the tilt axles.

2. Lift the upper section and put the tilt axle that faces

away from the base machine into position.

3. Put the tilt axle that faces the machine into position and

push it in sufficiently for it to reach the inner edge of the

upper section axle hole.

IMPORTANT

Shimming must not be done on

the front edge. Risk of property

damage.

4. Shim the upper section by placing shims on the inside

at the rear.

There may be no appreciable clearance.

5. install the tilt axle lock screws.

46

Loading...

Loading...