6 Maintenance

- that the quick coupler is operating normally; that it is clean and without play or any other

visible defects

- that no abnormal axial or lateral play is present. If suspected, see section 6.6.

Checking axial and radial play.

- that there are no hydraulic leaks; replace worn or damaged hydraulic hoses.

- that the locking function and spring loading on the quick coupler lock switch are

working.

- That the quick coupler lock buzzer works (this check only applies to integrated locks;

otherwise refer to the base machine's or relevant supplier's user manual).

- that no grease leakage is present on hoses or in connectors

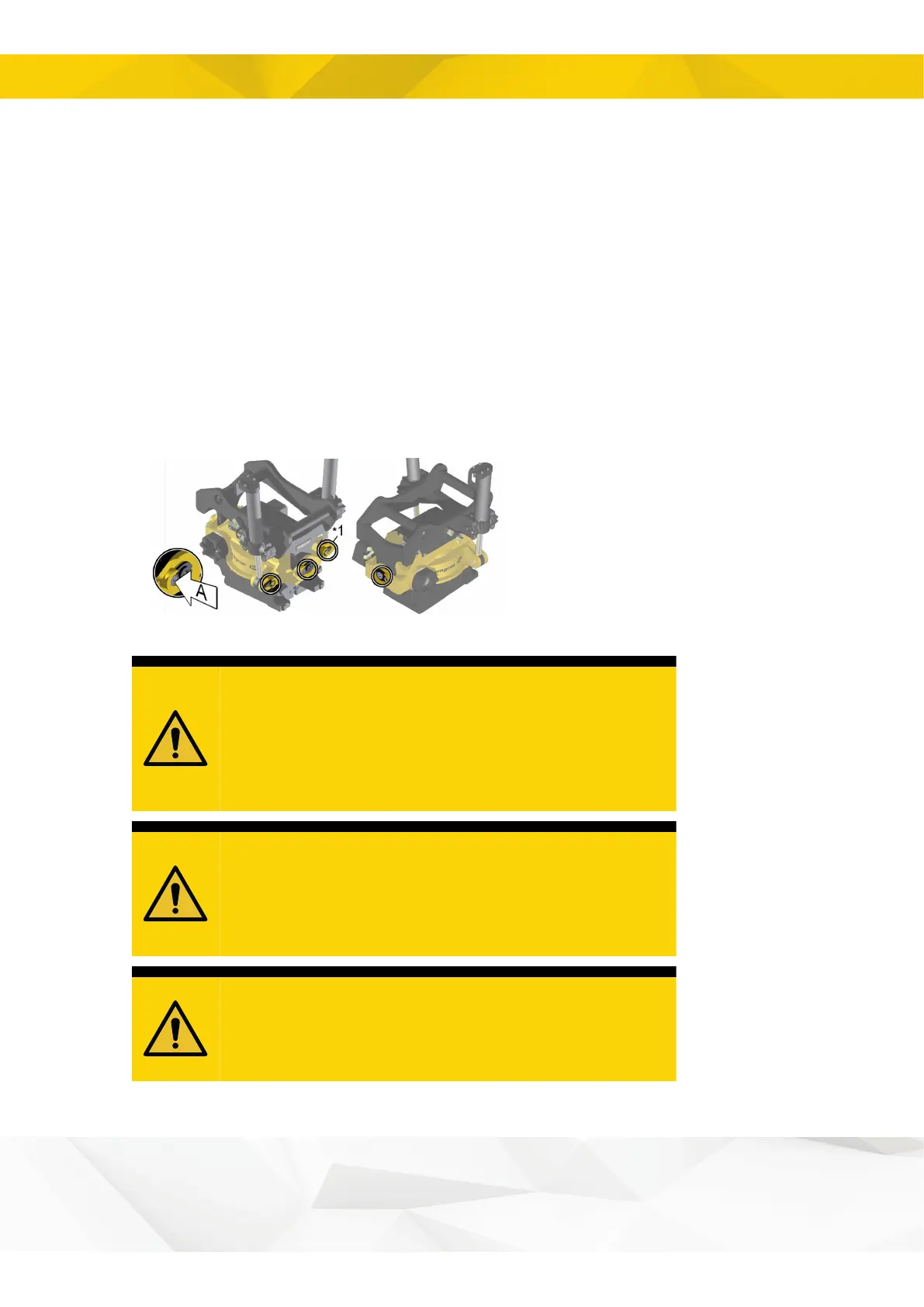

- that shaft journal lock attachment points (A) are not loose. Shaft journal lock design

may differ from the images below depending on the tiltrotator model. Not EC02 or

EC05.

- that Q-Safe sensors (option EC30) are free of dirt and metal.

WARNING

Always make sure the locking bolts protrude as

specified for the quick coupler concerned. Tools

connected to the tiltrotator may only be used if

locking has been correctly performed. Risk of

personal injury and damage to property.

WARNING

Welding is not permitted. It can have a negative

impact on safety. Risk of personal injury and damage

to property. For welding, contact your dealer or

engcon Nordic AB.

WARNING

Replace damaged or illegible signs and decals before

using the machine. Risk of personal injury and

damage to property.

40

Loading...

Loading...