fig_3_1

12

EUROMAG | MC608 | TD210-1

www.euromag.com

3. INSTALLATION OF

THE SENSOR

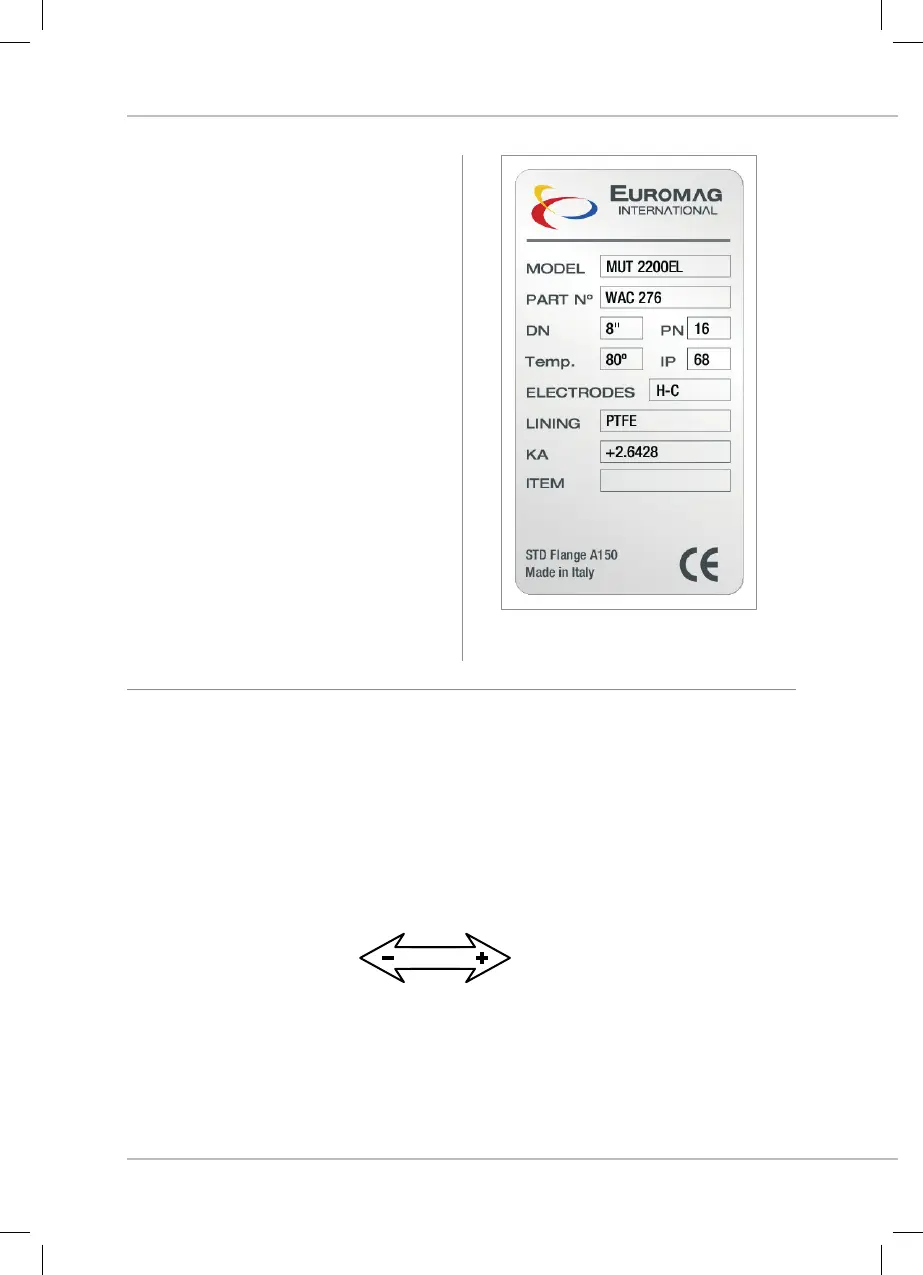

3.1 IDENTIFYING DATA PLATE

The plate located on the sensor carries the

following data:

• MODEL:

• PART No.: the part number identifying the

device (identification number for tracing the

identity)

• DN: nominal diameter [inches or mm]

• PN nominal pressure [bar/s]

• Temp.: maximum process temperature

• IP: international degree of protection

• ELECTRODES: composition of the material

making up the electrodes

• LINING: internal lining material

• KA: calibration coefficients

• ART.: other special guidelines

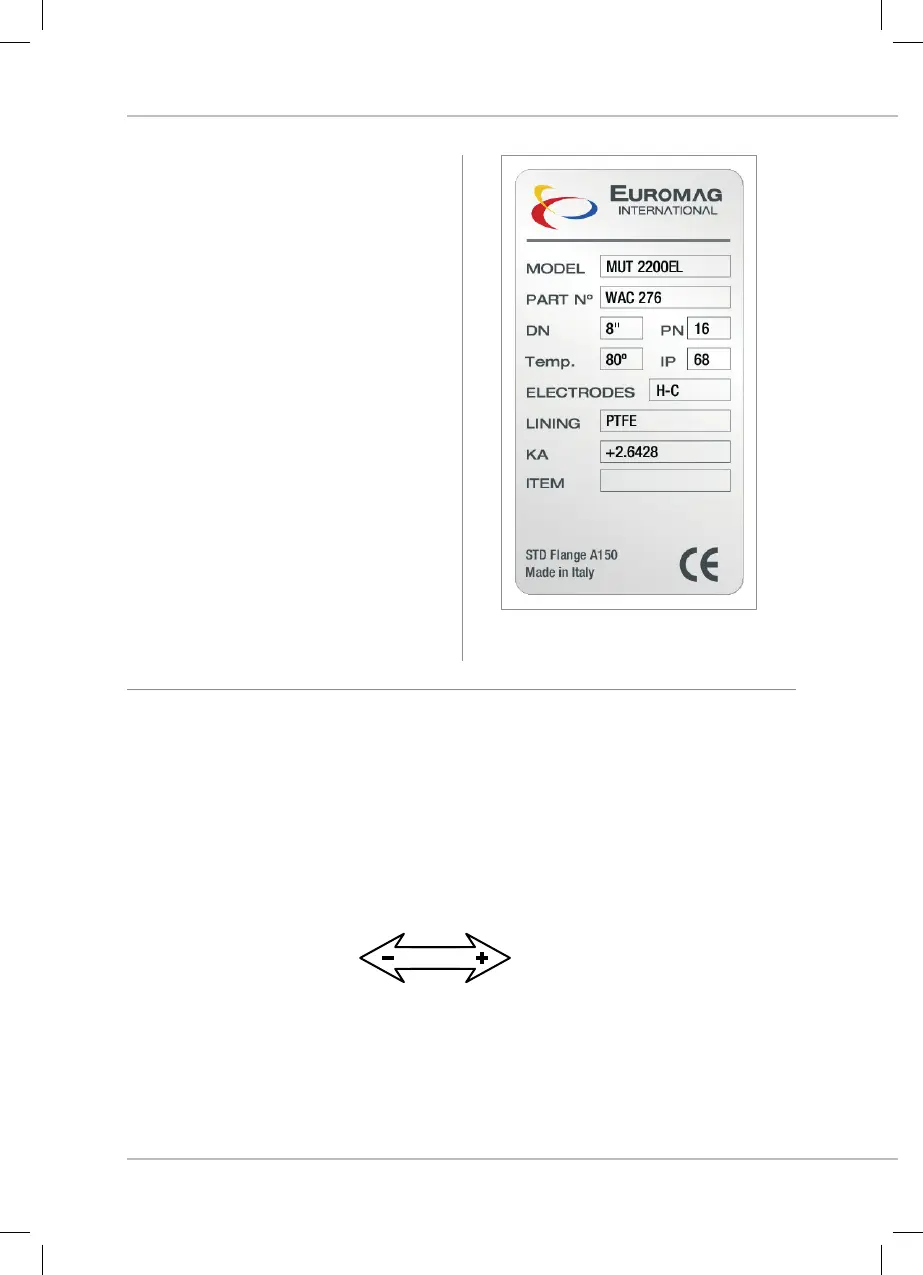

3.2 BIDIRECTIONAL READING

In the sensor, if the liquid flows:

• in the same direction of the arrow (enter by – and exit by +), the flow is positive and the display will

show a reading with no sign;

• in the opposite direction to that indicated by the arrow (enter by + and exit by –), the flow is negative

and the display will show a reading with negative sign;

FLOW

direct flow -> figure without signnegative figure-> reverse flow

Loading...

Loading...