116

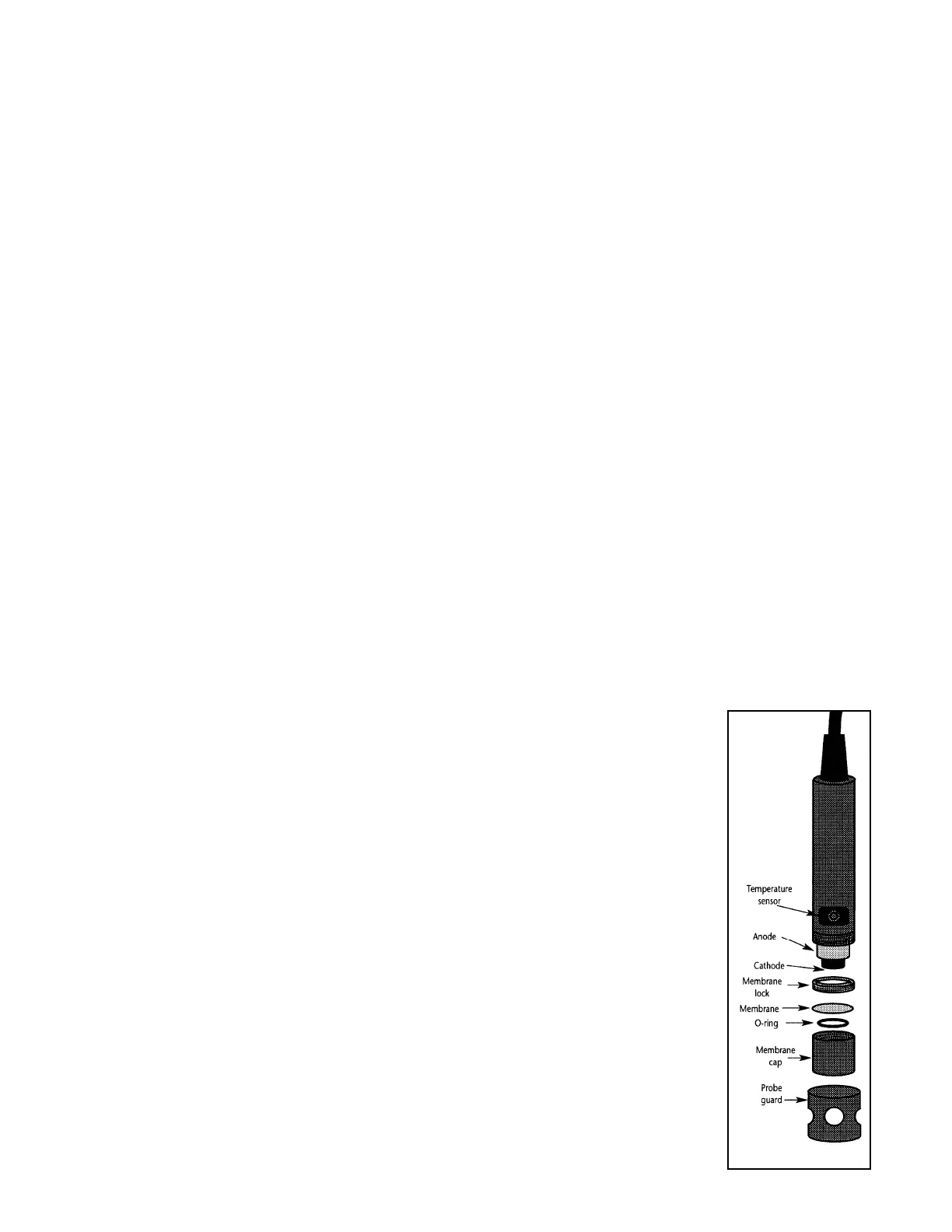

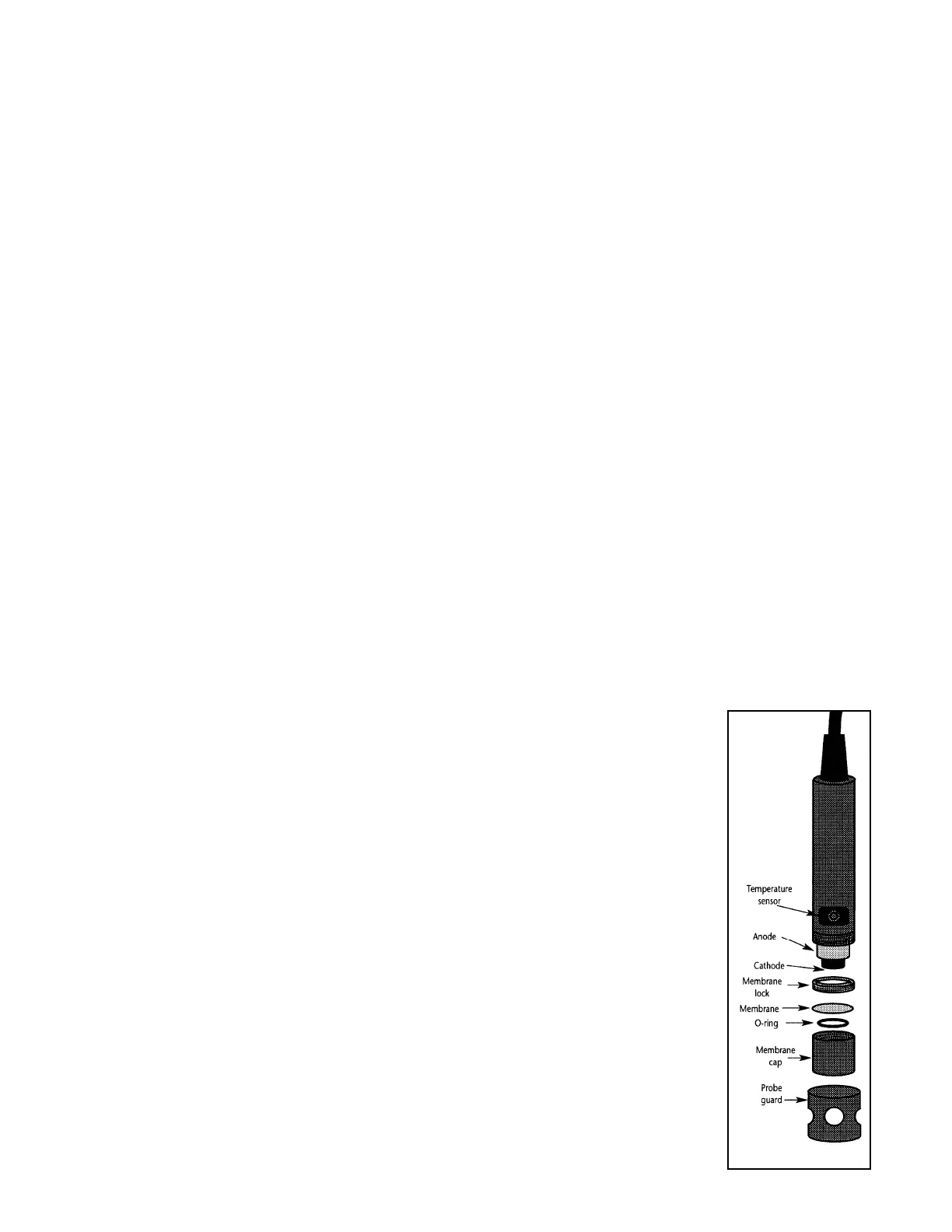

Figure 63: Positioning

of O-ring & Membrane

2. Hold the probe under hot running water and brush away the white

oxide on the cylindrical anode with a stiff plastic brush – do not use

metal cleaning material.

3. If the cathode has any deposits, remove them with a light scouring

powder. Do not polish the cathode.

4. Fill the new membrane cap housing with electrolyte solution and

inspect the bottom for leaks. If the solution drops are leaking from the

membrane, use new cap housing.

5. If the assembly is leak-free, fill the membrane cap housing with

electrolyte to the brim.

6. Tap the side of the housing gently to remove any air bubble that may

be sticking to the membrane.

7. Screw the cap onto the probe. Excess electrolyte will drain out.

8. Replace probe guard.

9. Calibrate the probe after the % saturation readings have stabilised.

3.2.4 Membrane/O-ring Replacement (Optional Procedure)

It is recommended only experienced service personnel can perform this

procedure.

This procedure is OPTIONAL, and should only be performed if you have

new membrane and O-ring. You are also required to have a membrane

installation tool. These items are available as optional accessories in the

“Accessories” section.

1. Pull off the probe guard.

2. Unscrew the membrane cap from the probe.

3. Hold the probe under hot running water and brush away

the white oxide on the cylindrical anode with a stiff plastic

brush – do not use metal cleaning material.

4. If the cathode has any deposits, remove them with a light

scouring powder. Do not polish the cathode.

5. Using the installation tool, unscrew and remove the

membrane lock from the membrane cap. See Figure 64 on

the following page.

6. Remove the membrane and O-ring. Discard both.

7. Rinse the membrane cap and membrane lock in tap water.

8. Install a new O-ring inside the membrane cap.

9. Install a new membrane. Make sure the membrane covers

the O-ring all around its circumference.

Loading...

Loading...