Operation

B.Inserttheheightadjustmentpinintothehole

correspondingtothedesiredcuttingheight.

Seethedecalonthesideofthedeckliftplate

forcutheights.

6.Adjustthesidewingdecks:

A.Makesuretheengineisoff,thekeyhasbeen

removed,andthedeckwingsarelockedin

place.

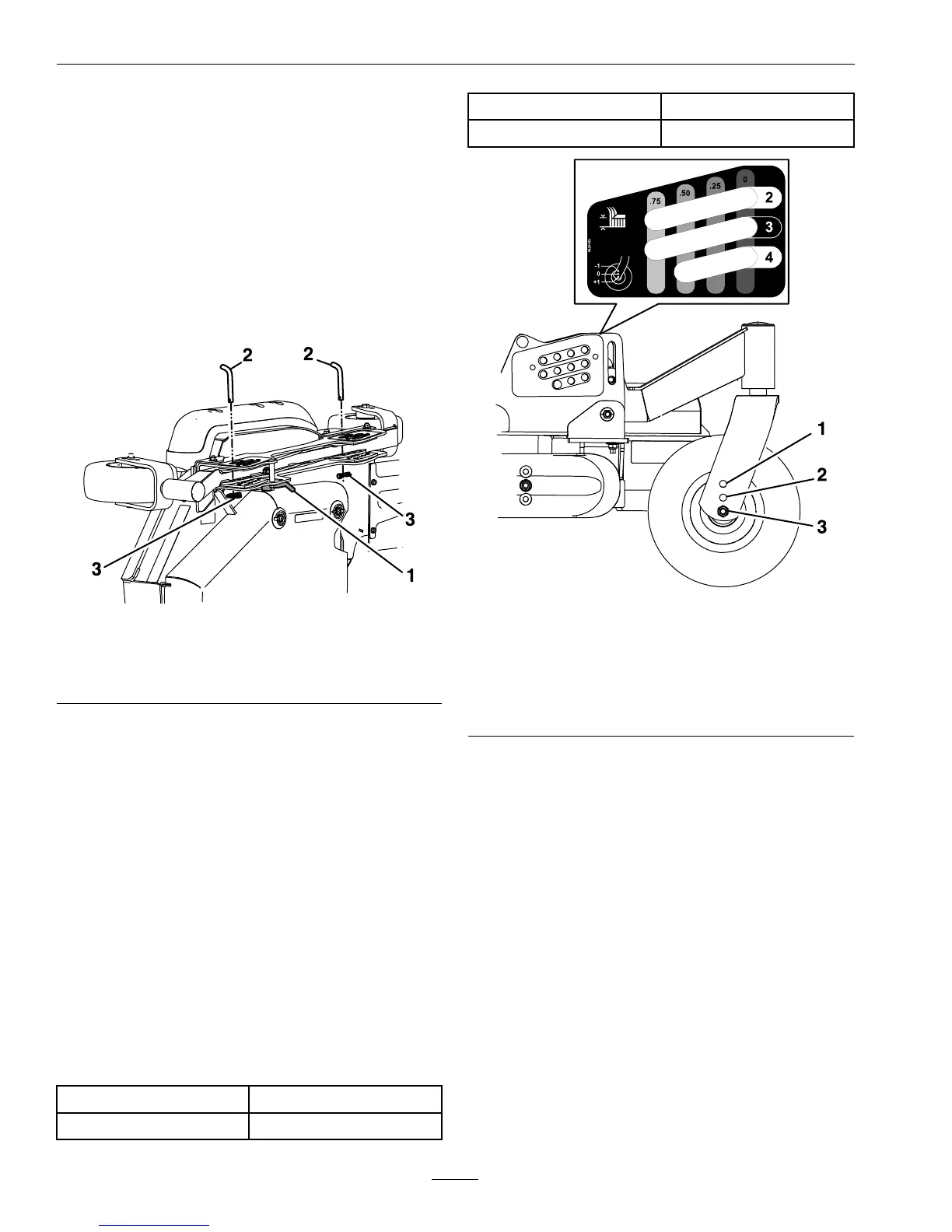

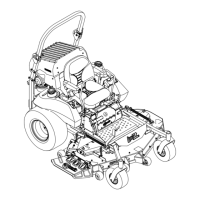

B.Unlockthecamlockslocatedontheheightof

cutchannelonthewingdeck(seeFigure17).

g239055

Figure17

1.Unlockcamlock3.Lynchpin

2.Heightofcutpin

C.Removethelynchpinfromtheheightofcut

pinonboththefrontandrearchannels.

D.Movethewingdecktotheappropriateheight

andreinstalltheheightofcutpinsandlynch

pinsasshowninFigure17.

E.Lockthecamlock.

F.Repeatforotherwingdeck.

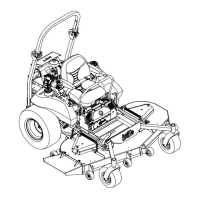

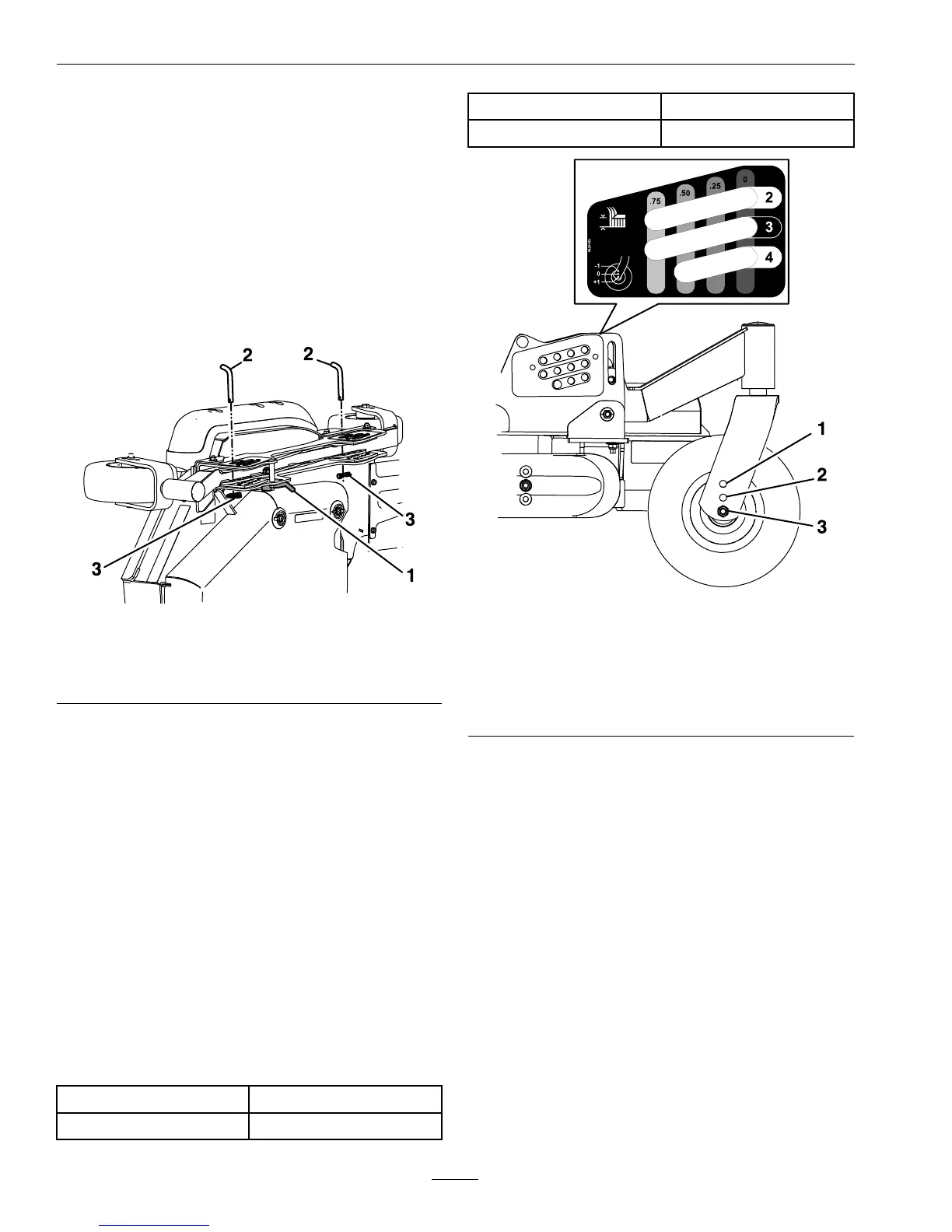

7.Ifadditionalheightofcutrangeisdesired,adjust

thefrontandreargaugewheelsonthewingdeck:

A.Removethemountinghardwarefromthe

gaugewheel.

B.Adjustthefrontandreargaugewheelstothe

appropriateholelocation(seethechartbelow

andFigure18)andreinstallthemounting

hardware.

HoleLocationHeightofCutRange

Tophole(-1ondecal)

1–3.5inches(25–89mm)

Middlehole(0ondecal)

2–4.5inches(51–114mm)

Bottomhole(+1ondecal)

3–5.5inches(76–140mm)

g212253

Figure18

HeightofCutRange

1.Tophole(-1ondecal)

2.Middlehole(0ondecal)

3.Bottomhole(+1ondecal)

C.Repeatforotherwingdeck.

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

positionwhentheheightofcuthaschanged.

1.Stopthemachineandmovethemotioncontrol

leversoutwardtotheneutrallockedposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthemounting

hardware.

6.Placetherollersinoneofthepositionsshown

(Figure19).Rollerswillmaintain3/4inch(19

34

Loading...

Loading...