22

180˚

180˚

!

"

! "

#

#

$

%

% %

& &

$ $

"

!

!

"

#

M10 x 25 M10 x 25M10 x 16

Dust Extractor

RL 250 / RL 300 / RL 350

6.2.2 Chip container (Standardaus equipment)

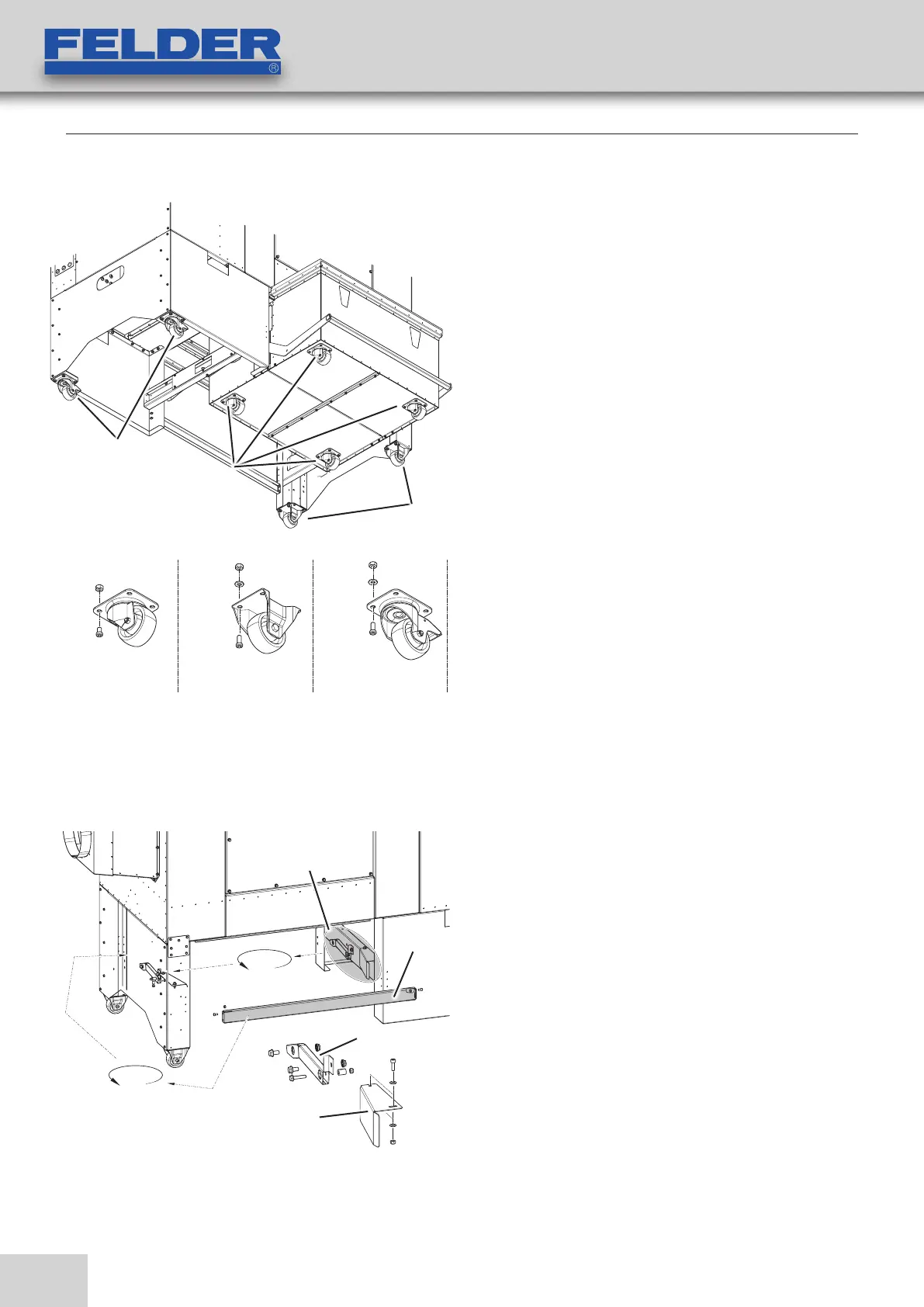

Fig. 6-2.2: Mirror-inverted operation

6.2.3 Mirror-inverted operation

The dust collecting container can be pushed under the

extractor from the other side if there is a shortage of

space.

Screw the supporting bracket, rotated by 180°, onto the

opposite side of the machine.

Screw the stop plate, also rotated by 180°, onto the front

side of the machine.

!Supporting bracket 1

"Supporting bracket 2

#Stop plate

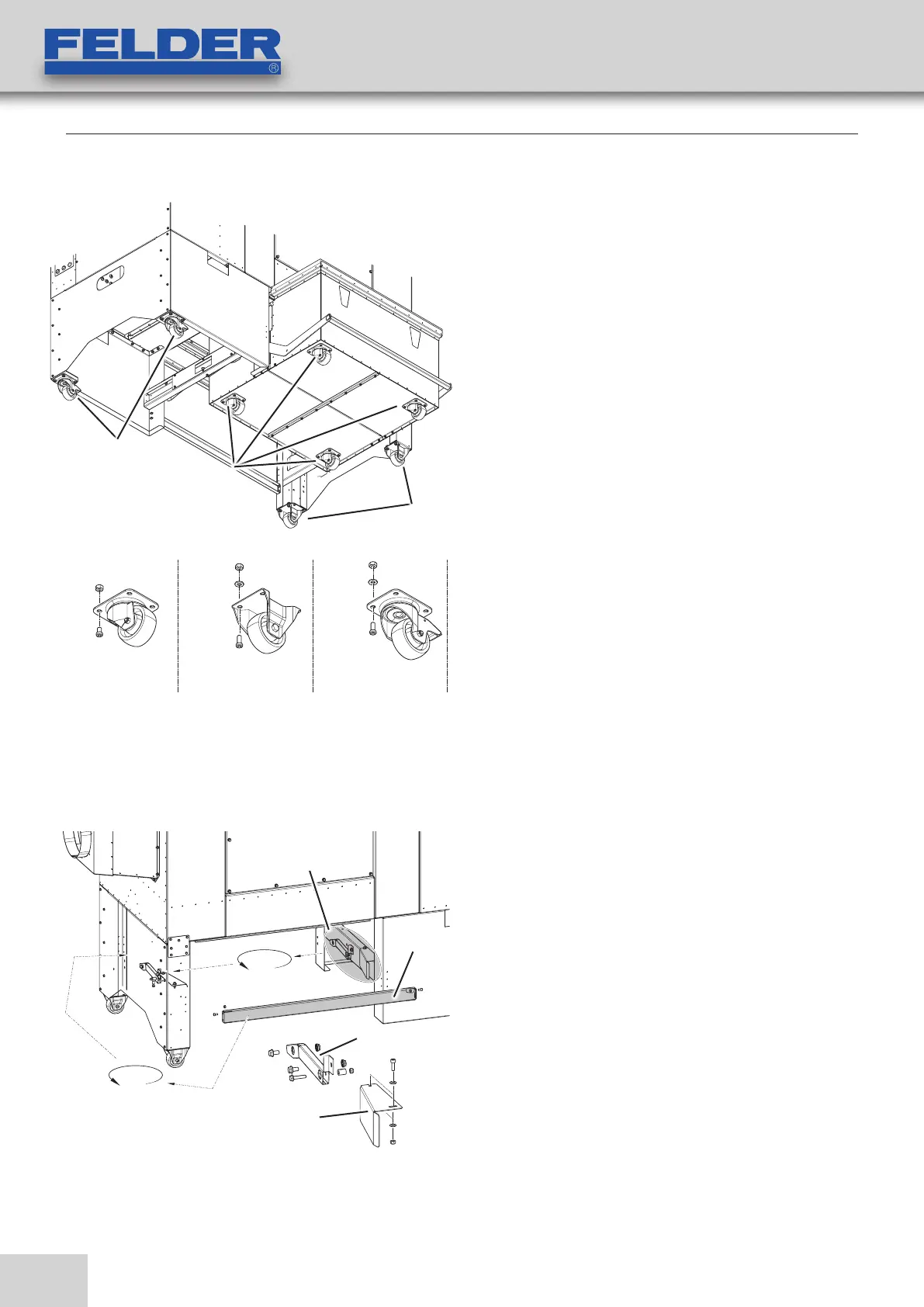

Setup and installation

Before you can work with your dust extractor, you must

screw the wheels to the chip container and the base

unit.

The chip container is equipped with 4 steering rollers.

Screw the steering roller to the chip container using the

supplied screws and nuts.

The base unit is equipped with 2 steering rollers and 2

fixed rollers. Screw both steering rollers and both fixed

rollers to the base unit using the supplied screws and

nuts.

Fig. 6-2.1: Steering rollers / Fixed rollers

!Steering rollers (Chip container)

"Fixed rollers

#Steering rollers (with brake)

$Screws

%Nuts

&Shims

Loading...

Loading...