43

Dust Extractor

RL 250 / RL 300 / RL 350

Annex

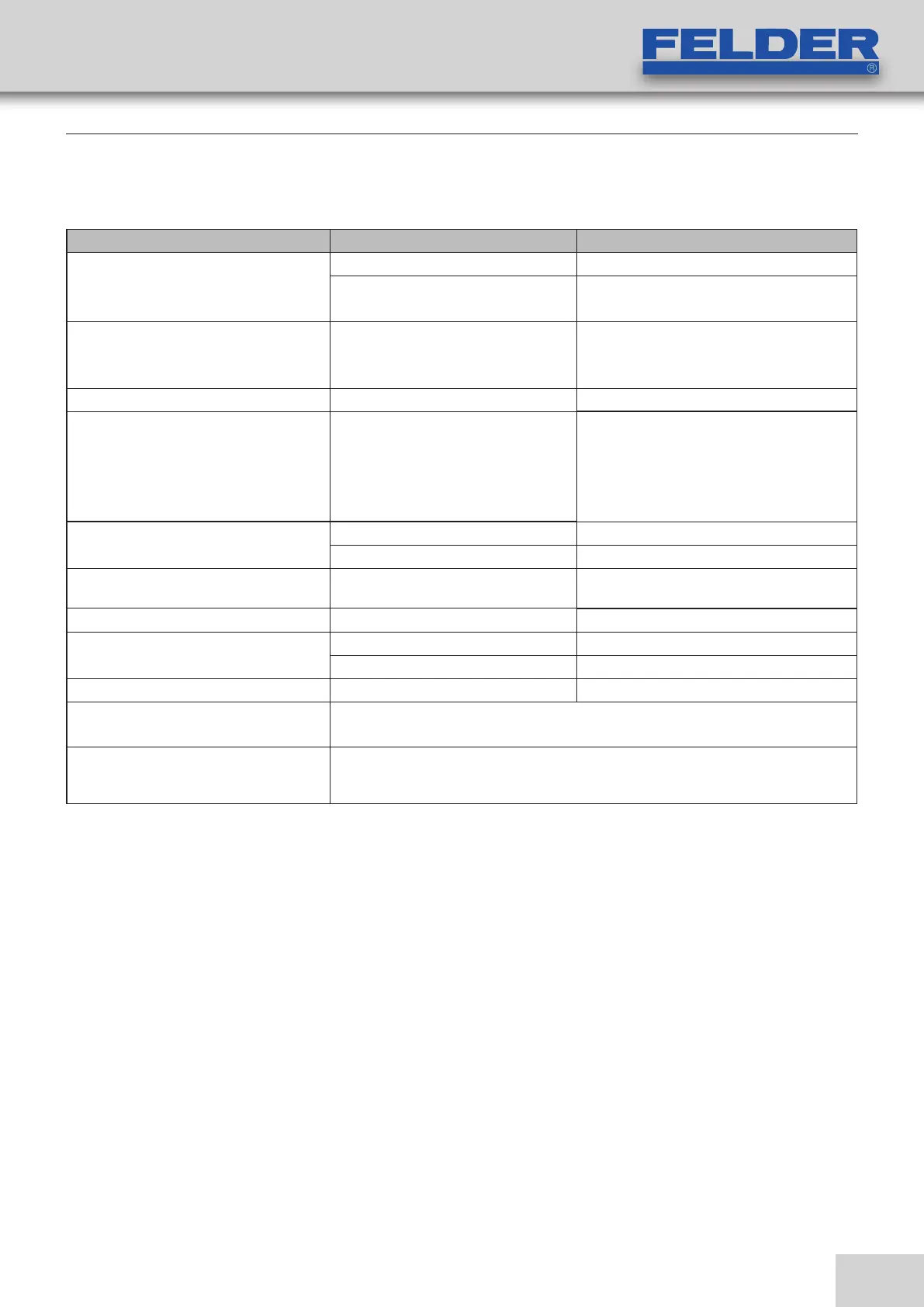

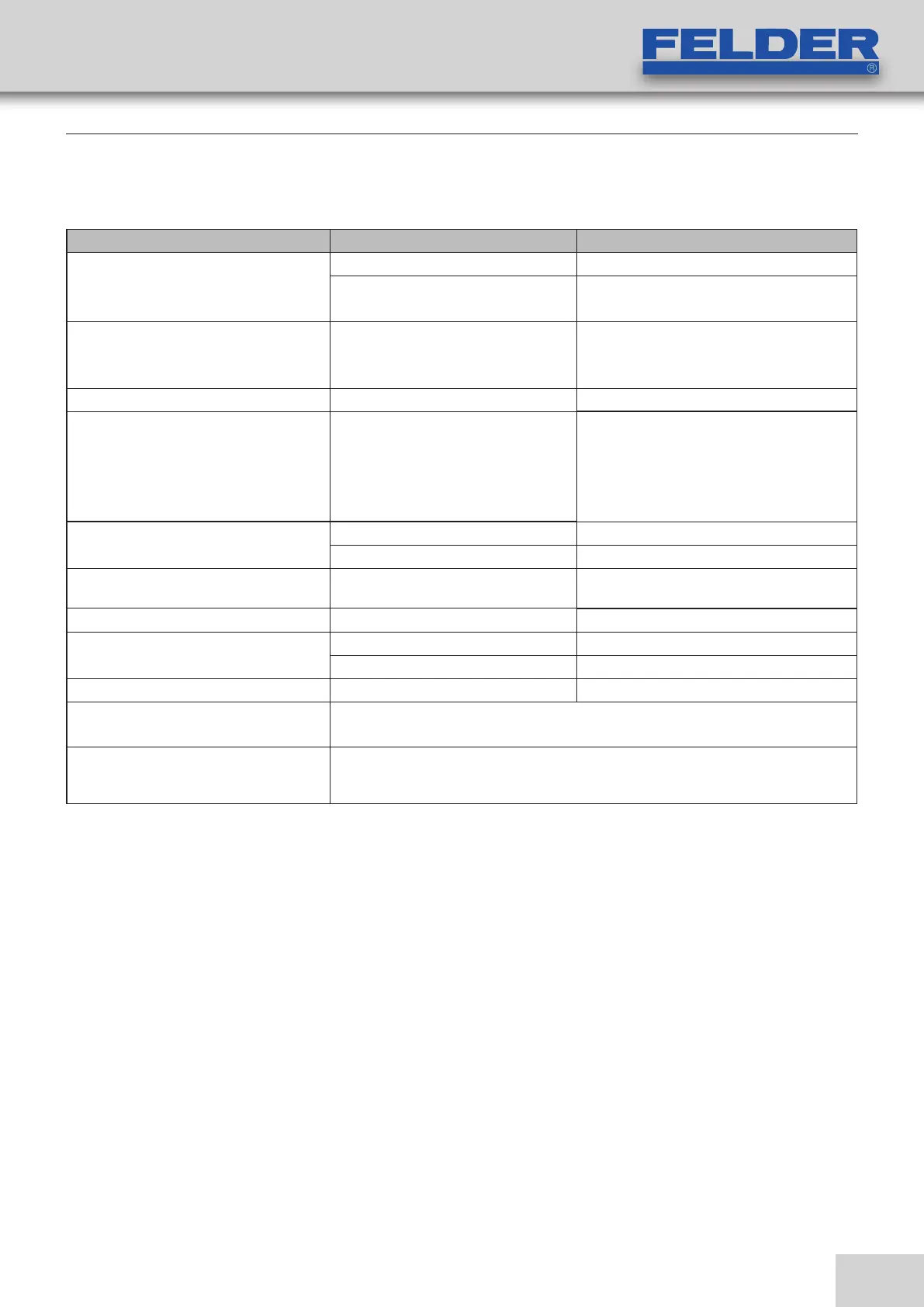

8.11 Faults, causes and repairs

Fault Cause Repair

Machine does not start Main switch at setting „0“ Check switch position

Error in the electrical contact. Check the electrical connection (connecting

lead, fuses).

Fire extinguisher has been triggered

(case of fire)

After the fire extinguisher was triggered a

service by a FELDER technician is manda-

tory!

Warning light lights up (Differential pres-

sure switch / Control panel)

The pressure switch monitors the de-

gree of soiling of the filter through the

differential pressure measurement.

Clean the filter, Renew the filter.

Attention material damage! This setting may

not be modified, however if required, it may

only be executed by a person authorised to

carry out this task.

The vacuum performance is sinking. Dirty filter. Clean the filter.

Filter defect Renew the filter.

if vacuum output is very low Incorrect direction of rotation (Drive

motor, Fan propeller)

Change direction of the Motor rotatation

The chips are falling out of the bag. Filter defect Renew the filter.

The chipbag has a defect. Renew the chip bag.

The fan wheel is running incorrectly. Unclean / dirty fanwheel Contact service technician

Vibrations Use a piece of so-called ”coil hose” to connect your dust collector to the dust collec-

ting system to avoid forwarding vibrations to the system.

the chip bags will be sucked upwards The seal between the chip container and dust collector must be tight, otherwise the

chip bags will be sucked upwards and the unit will not function correctly!

Check the seal periodically and replace if needed.

Loading...

Loading...