Fav 900

Engine / Injection valves

Checking injection nozzles

E

Testing

Fav 900 chassis number 23/3001and up

05.02.2001

2712 000001

E

a

2/3

Capitel Docu-No.

Index

Date Version

Page

Checking injection nozzles

Nozzles meeting these three requirements may be used again.

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

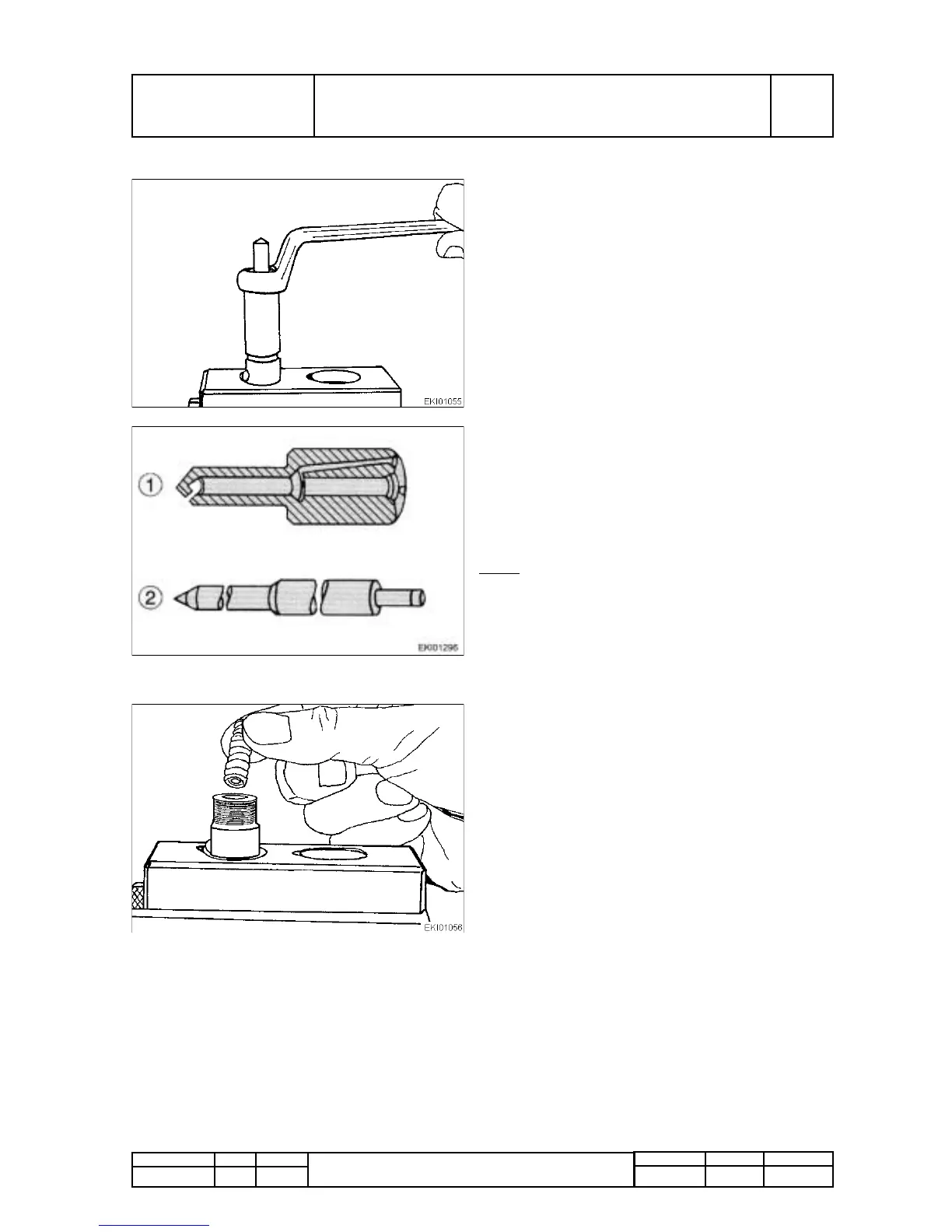

Dismantling injection nozzle

With the inlet opening facing downwards, fit

nozzle holder and nozzle assembly into the

holding device and clamp unit into the vise.

Unsrew threaded union, remove nozzle body,

intermediate washer, pressure screw,

compression spring and adjusting washer.

Remove the pressure pipe from the vise.

PMTAB_Picture

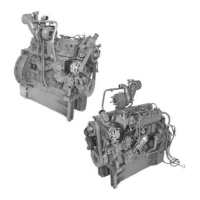

Overhauling injection nozzles

using a small piece of wood and petroleum or

diesel fuel, clean interior of nozzle (1).

With a clean rag remove dirt from needle valve (2).

Coked up needle sections can be placed on a

lathe and cleaned with a soft wooden stick dipped

in oil.

Note:

To prevent corrosion, do not touch rectified

surfaces of the needle valve.

Needles and nozzles are paired and must not

be interchanged.

Check clean components for wear and damage ;

replace if necessary. Degrease all new parts.

PMTAB_Picture

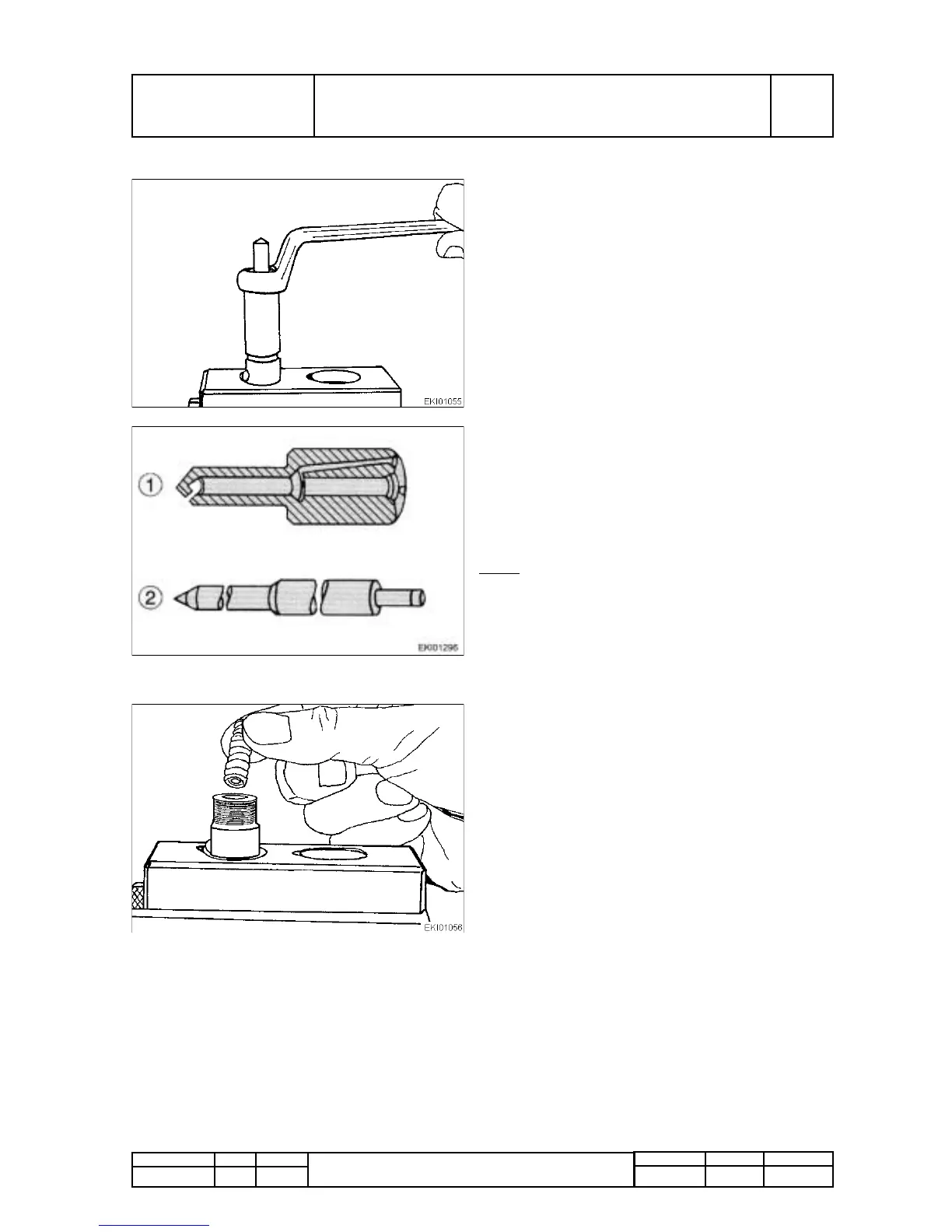

Reassembling injection nozzle

Remove pressure pipe connector from the vise

and refit compression spring and adjusting

washer.

Loading...

Loading...