TOR

37

cod. 3542B750 - Rev 05 - 07/2022

RO

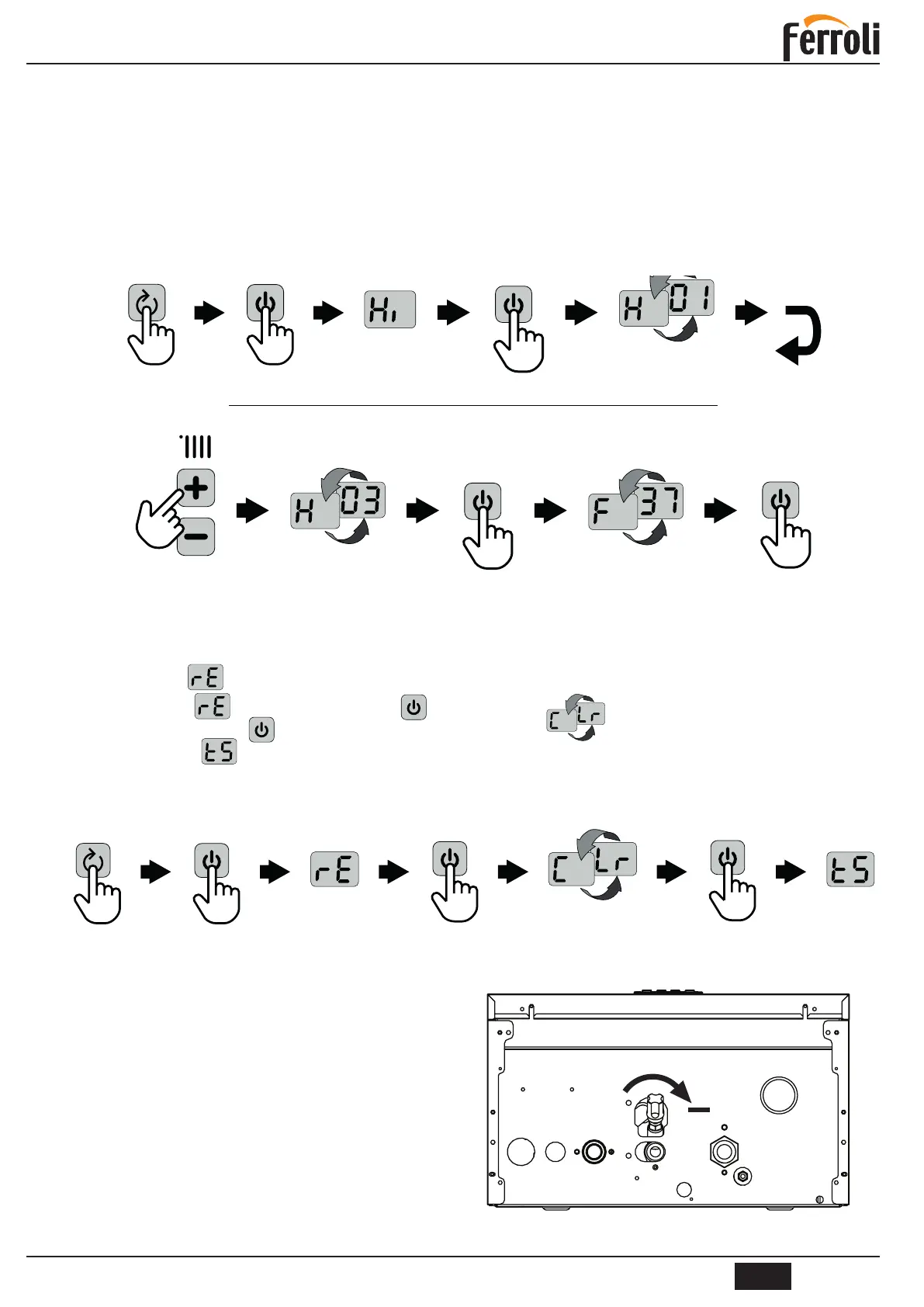

1.5.2 Istoric alarme

Cazanulpoatestocaultimele10defecțiuni.H01reprezintăceamairecentădefecțiunecareaavutloc.

CoduriledefecțiunilorsalvatesuntașateșiînmeniulrelevantalcontroleruluiOpenTherm(depindede

disponibilitateacontrolerului).

Odatăintratînmeniuldeservice„Hi”,apăsațibutonulPORNIT-OPRITpentruavericaultimadefecțiune.

Apăsațitastele“+”sau“-”Încălzirepentruaderulalistadefecțiunilor.

Pentruaieșidinmeniuldefecțiunilorboilerului,apăsațibutonul“înapoi”pânăajungețilaecranulprincipal

exemplu: cumseciteștecoduldeeroareH03

1.5.3 Resetare lista erori

Prinselectarea înmeniuldeserviceesteposibilsăștergețilistadefecțiunilorstocate.

Dupăselectarea meniu,apăsațitasta,apoisimbolulvaclipiindicândfuncțiadeștergere.

Apăsațidinnoubutonulpentruaconrma.

Așajulrevinela meniu.

TOR

cod. 3542B750 - Rev 00 - 05/2022

10

EN

1.5 SERVICE MENU

To enter on the service menu press the “back” key for at least 5 seconds under any state (except for parameter setting

state or when the panel breaks down).

The display show

(parameters) and it can be changed into other menu (fault history) or (reset faults) by

pressing

1.5.1 Parameters

When the display show it is possible to enter on the parameter code by pressing the key.

The symbol flashing appears

, meaning the first parameter is show: to check the value press the key.

Parameter code Parameter name Range Default value Remark

P01 Water pump post-circulation (1 ÷ 20 minutes) 20

P02 Switch on heating temperature 5 ÷ 20 °C 8 °C

When the heating temperature is below the

Set Point - P02, the heating elements are

enabled to start

P03 Water switch type 0 ÷ 1 0

0 = on/off

1 = sensor type

P04 Switch on tank temperature 5 ÷ 10 °C 5 °C

When the tank temperature is below the

Set Point - P04, the heating elements are

enabled to start

P05 Storage tank 0 ÷ 1 0

0 = external tank disabled

1 = external tank enabled

P06

Offset temperature of heating

room compensation control

30 ÷ 50 30 (1.4.9.1 on page 9)

P07

Compensating curve of heating

outdoor compensation control

0 ÷ 10 0

0: No outdoor compensation control

1~10: Compensating curve C01-C10

P08 Maximum power 1 ÷ 6

6 ÷ 12 KW= 3

18 ÷ 24 KW= 6

It defines the maximum number of the wor-

king elements.

P09 A08 Fault defection option

00: No detection

03: Detection

00

P10

Heating comfort mode (heat

balance option)

00 ÷ 01 00

00 = comfort

01 = heat balance

(1.4.5.1 on page 8)

P11 Air Purge function 0 ÷ 1 0 1 = activate the Air Purging function manually

P12 Sterilization temperature 55 ÷ 70 °C 65 °C

This is the temperature at whitch the boiler is

load during the sterilization function

P13 Water tank sterilization period 1 ÷ 31 days 7 days Period for this function

Note: Manually exit from the set state after setting and power down the system after waiting for a while (generally 3-6s

because the system is saving the parameter) because the system saves the parameter under the non-set state, or

the parameter won’t be saved. The outdoor temperature compensation setting is also subject to the restriction.

Example: how to modify the P02 value

x5 s

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

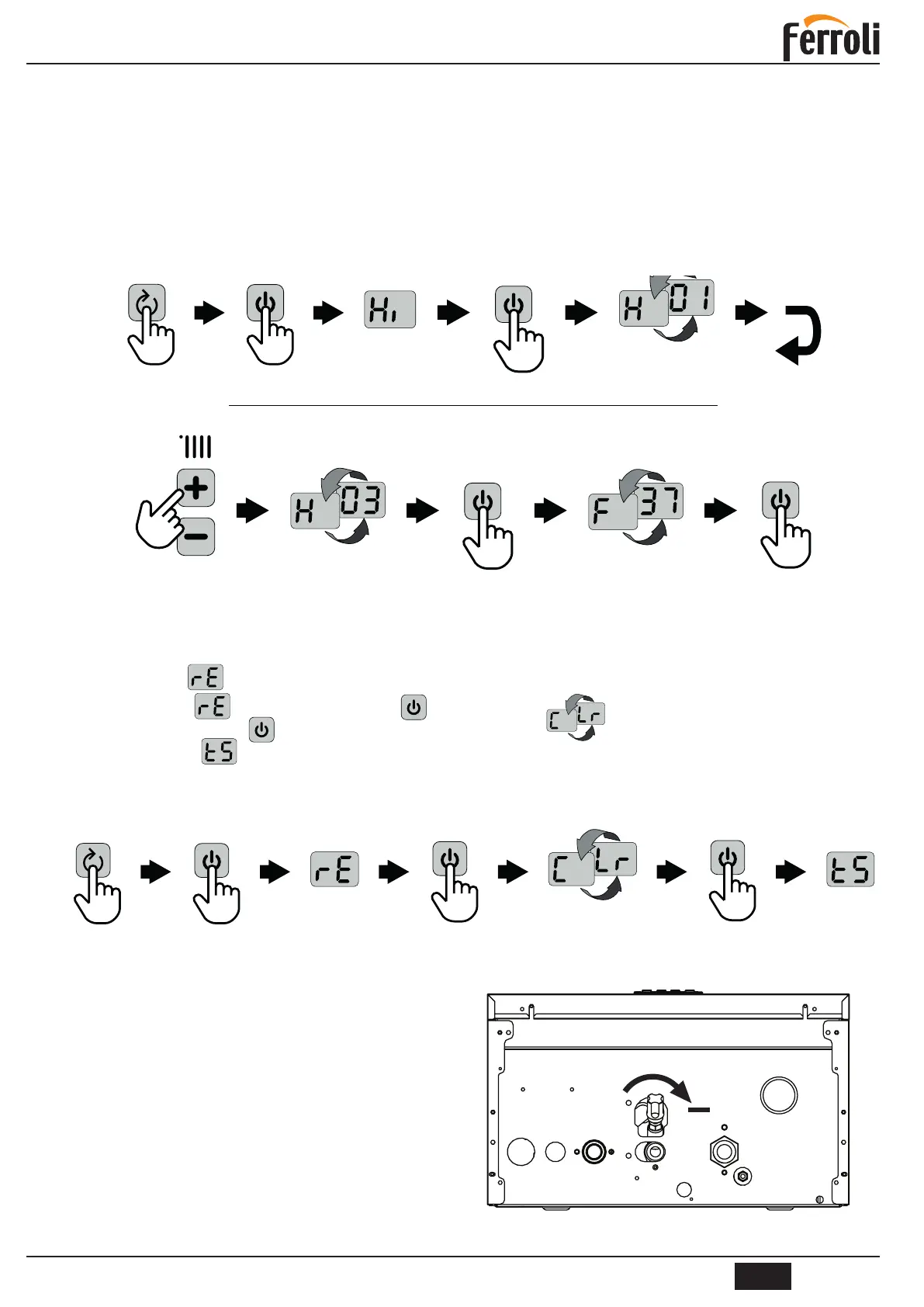

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

TOR

11

cod. 3542B750 - Rev 00 - 05/2022

EN

1.5.2 Fault Hystory

The boiler can store the last 10 faults. H01 represents the most recent fault that occurred.

The codes of the faults saved are also displayed in the relevant menu of the OpenTherm controller (it depends on the

controller availability).

Once entered on the “Hi” service memu, press the ON-OFF to check the last fault.

Press the buttons “+” or “-” Heating to scroll the list of faults.

To exit the Boiler faults menu, press the button “back” until reaching the main screen

Example: how to read the H03 error code

x5 s x1

x2

1.5.3 Clear faults

By selecting the on the service menu, it is possible to clear the list of the stored faults.

After selecting the

menu, press the button , then the symbol will flash indicating the clear function.

Press again the button

to confirm.

The display returns to the

menu.

x5 s x2

1.6 FILLING OF THE INSTALLATION

The electric heating unit is provided with a ball valve to ll the

heating installation up to 1 ÷ 3 bars. During operation, in case

the pressure decreases in the system (because the air is remo-

ved from the system) to the minimum value of the above men-

tioned pressure, open the ll valve to supplement with water.

Turn the ll valve anticlockwise to supplement with water and

clockwise to close it. The electric heating unit operates usually

at 1÷1,5 bars. After lling, close the ll valve (“g. 5 - Water

lling valve”).

g. 5 - Water lling valve

1.6 Umplerea insalației

Centralatermicăelectricăesteprevăzutăcuun

robinetsfericpentruumplereainstalațieideîncălzire

la1–3bar.Întimpulfuncţionării,încazulscăderii

presiuniidinsistem(datoritaeliminariiaeruluidin

sistem)lavaloareaminimaapresiuniidemai

sus,deschideţirobinetuldeumplereînvederea

completăriicuapă.Rotiţirobinetulpentrualimentare

însensinversacelordeceasornicpentruacompleta

cuapăşiînsensulacelordeceasornicpentrua-l

închide.Centralatermicăelectricăfuncţionează,în

modobişnuit,la1-3bar.Dupăalimentare,închideţi

robinetuldeumplere.

1.5.2 Istoricalarme

1.5.3 Resetarelistaerori

1.6 UMPLEREAINSTALAȚIEI

Loading...

Loading...