8.4.3 Vacuum Hose

Check (to perform every 4h)

The vacuum hose has to be clean and

intact. It is mandatory that the hose has

no crack to not decrease the underpres-

sure. The suction hose is particularly

sensitive in the coupling areas between

the pipe and couplings and in tight

curves.

8.4.4 Filtro e Galleggiante

Check (to perform every 4h)

The filter has to be clean and it is im-

portant that nothing blocks or reduces

the floater mobility. The filter has to be

clean to avoid that water or dirt goes

inside the vacuum motor, the floater

has to be free to move and has to block

completely the air flow when it is in

blocking position (UP).

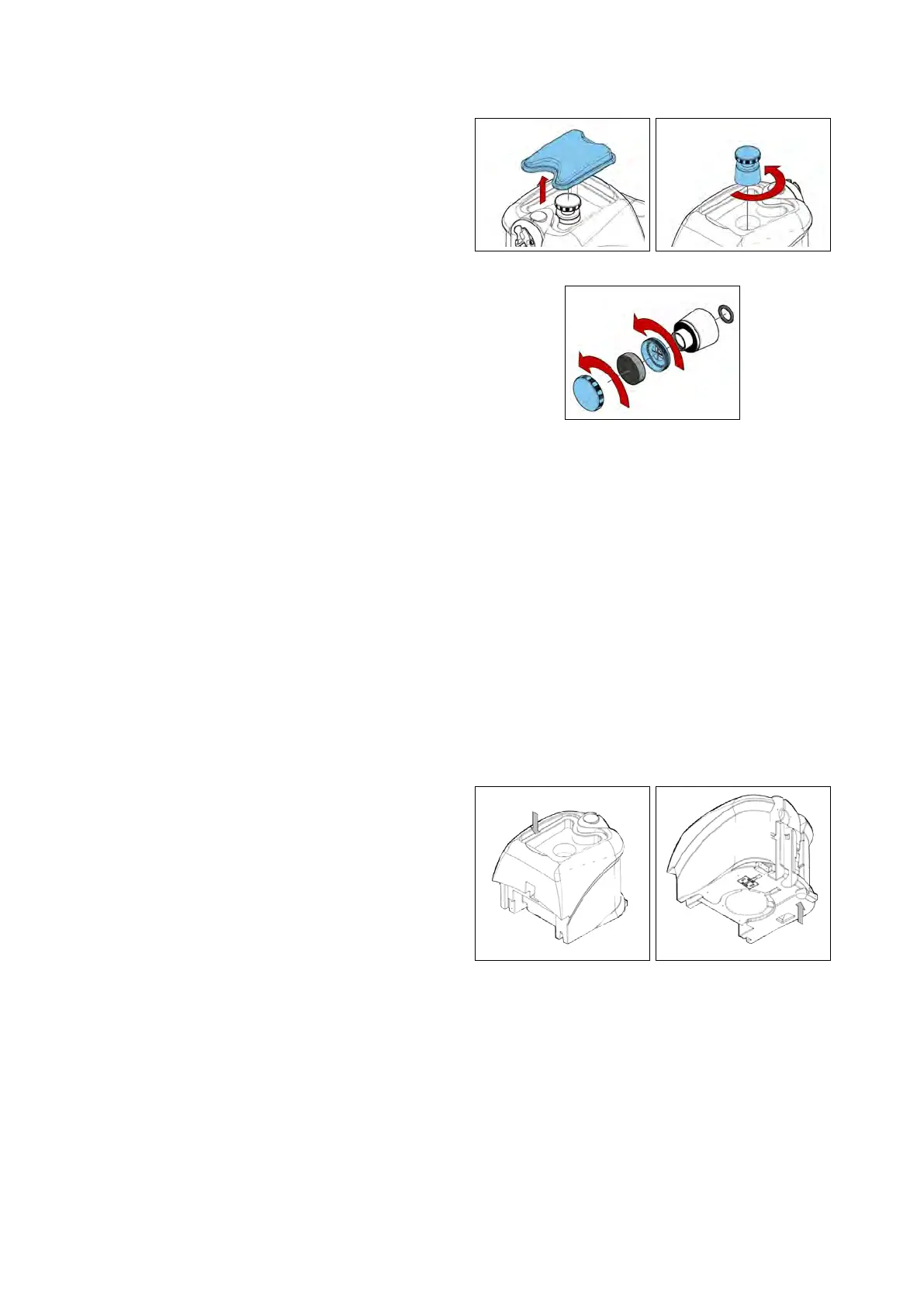

Maintenance (to perform every 4h)

• Put the machine in safe conditions.

• Check that the recovery tank is com-

pletely empty.

• Remove the recovery tank cover.

• Unscrew the filter and the floater.

• Remove and clean (replace if neces-

sary) the Gasket.

• Open the cap of the filter body.

• Remove and clean (replace if neces-

sary) the filter.

• Proceed at reverse to restore the

parts.

8.4.4-123 8.4.4-124

8.4.4-125

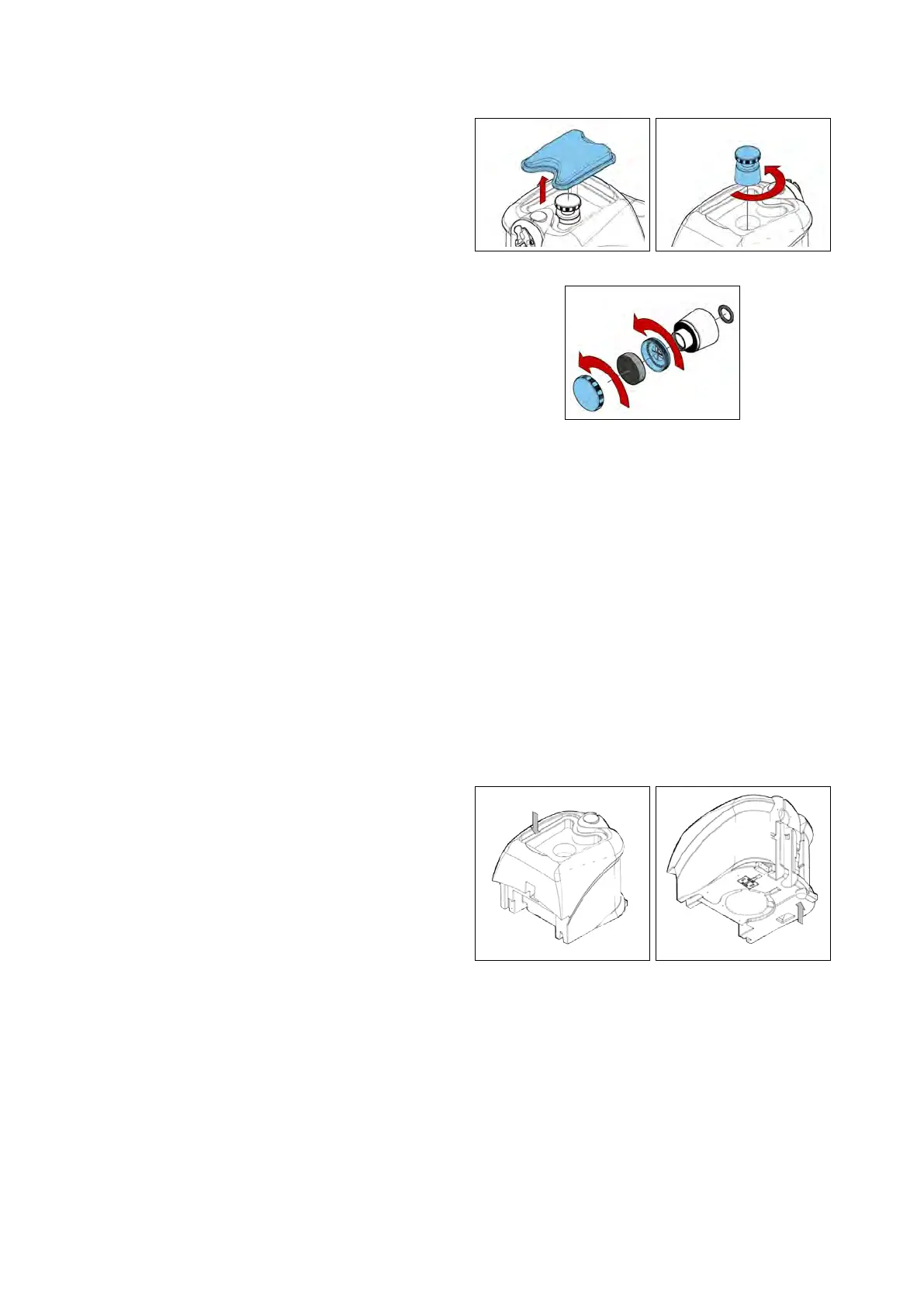

8.4.5 Recovery Tank

Check (to perform every 150h)

The recovery tank has to be clean and

has not to have cracks or, in general,

any kind of damage. The Lid housing

has to be even and flat to allow the

gasket to adhere perfectly to the tank

to avoid any air infiltration. The hose

fittings have to be in optimum condition

in order to avoid any dirty water leak-

age or any pressure drop during the job.

8.4.5-126 8.4.5-127

63

Loading...

Loading...