8.4.6 Vacuum Motor

Check (to perform every 150h)

The vacuum motor with the inlet com-

pletely open has to absorb less than 14

Amps.

The motor should rotate evenly and

smoothly and doesn’t have to produce

unusual noises. The motor contacts

have to be clean, they have not to show

signs of wear or heating in general.

The motor wires insulation has to be

intact in all its parts and does not show

signs of cracks. The single cable have to

be flexible.

The magnetic circuit of the motor has

to be in good conditions and clean.

The carbon brushes must be 6-8 mm

long and they have not to be abnormally

worn out.

Maintenance (to perform every 450h)

• Put the machine in safe conditions.

• Disassemble the motor from the ma-

chine (see section 5.3.6 at page 29).

• Remove the cooler fan plastic cover

from the motor.

• Remove the screws that secure the

carbon brushes

• Slip off the motor carbon brushes

• Replace the worn out carbon

brushes with new ones.

• Proceed at reverse to restore the

parts.

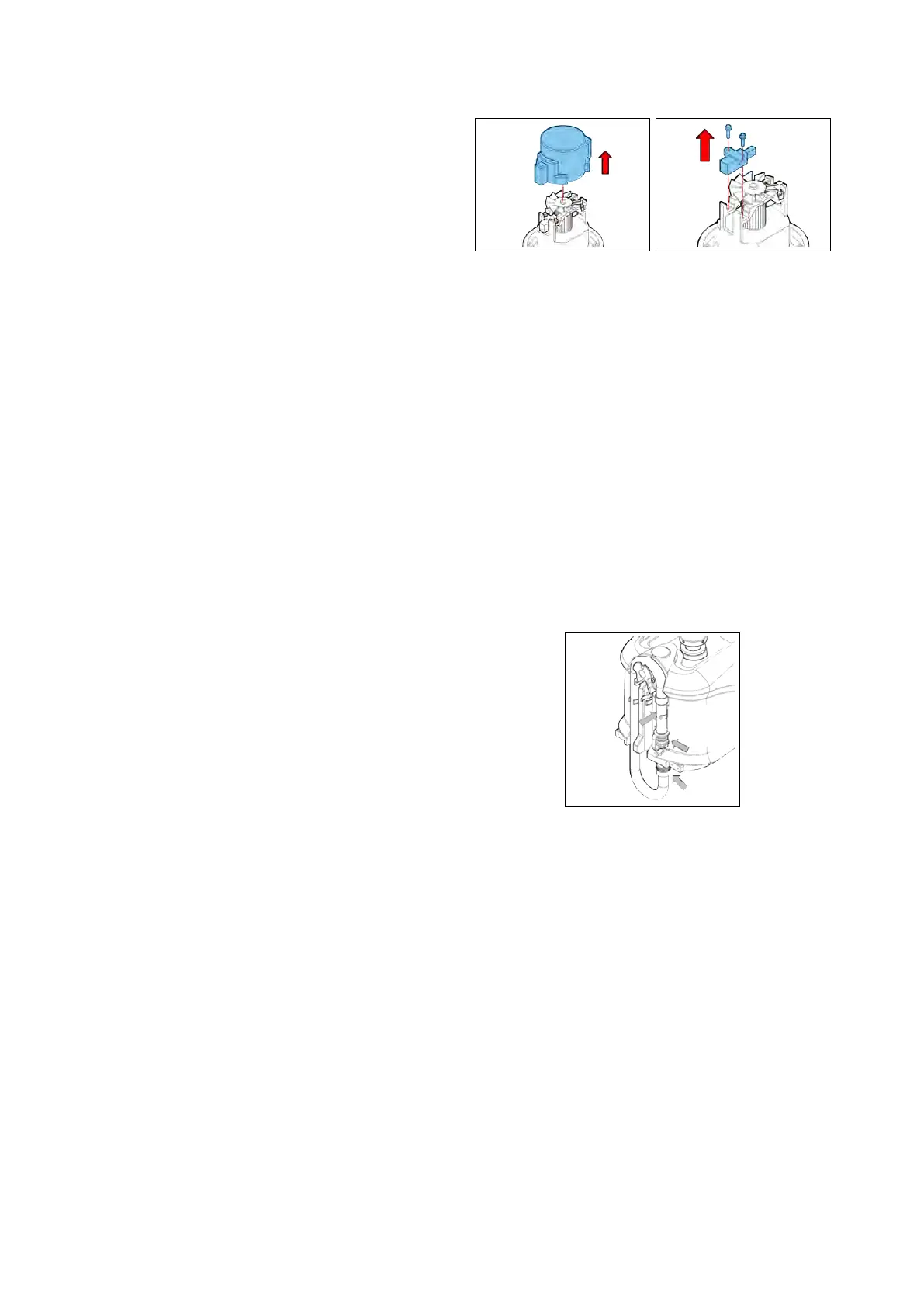

8.4.6-128 Plastic Cover

Removing

8.4.6-129 Carbon Brushes

Removing

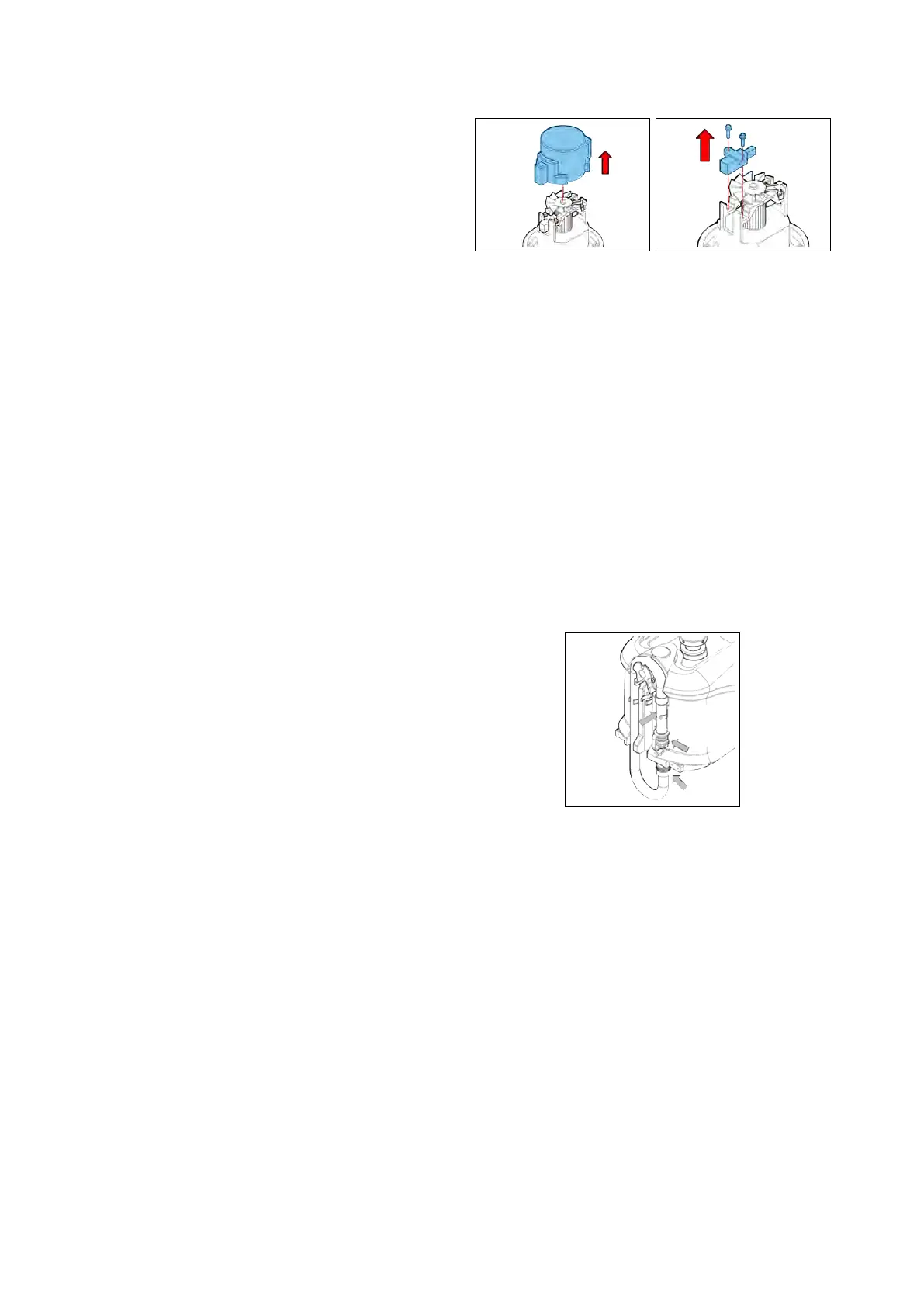

8.4.7 Drain Hose

Check (to perform every 4h)

The Drain Hose has to be perfectly fit-

ted in the recovery tank fittings in or-

der to avoid any dirty water leakage. The

Drain Cap has to seal perfectly the hose

to avoid any pressure drop or dirty wa-

ter leakage. The Drain Manifold has to

be flexible and has to have no cracks to

avoid any break down during the bend-

ing to drain the machine.

8.4.7-130

64

Loading...

Loading...