FLUXUS WW 4 General principles

14 UMFLUXUS_WWV1-1EN, 2018-02-28

4 General principles

In ultrasonic flow measurements, the flow velocity of the fluid in a pipe is determined. Further physical quantities (e.g., vol-

umetric flow rate, mass flow rate) are derived from the flow velocity and from additional physical quantities, if necessary.

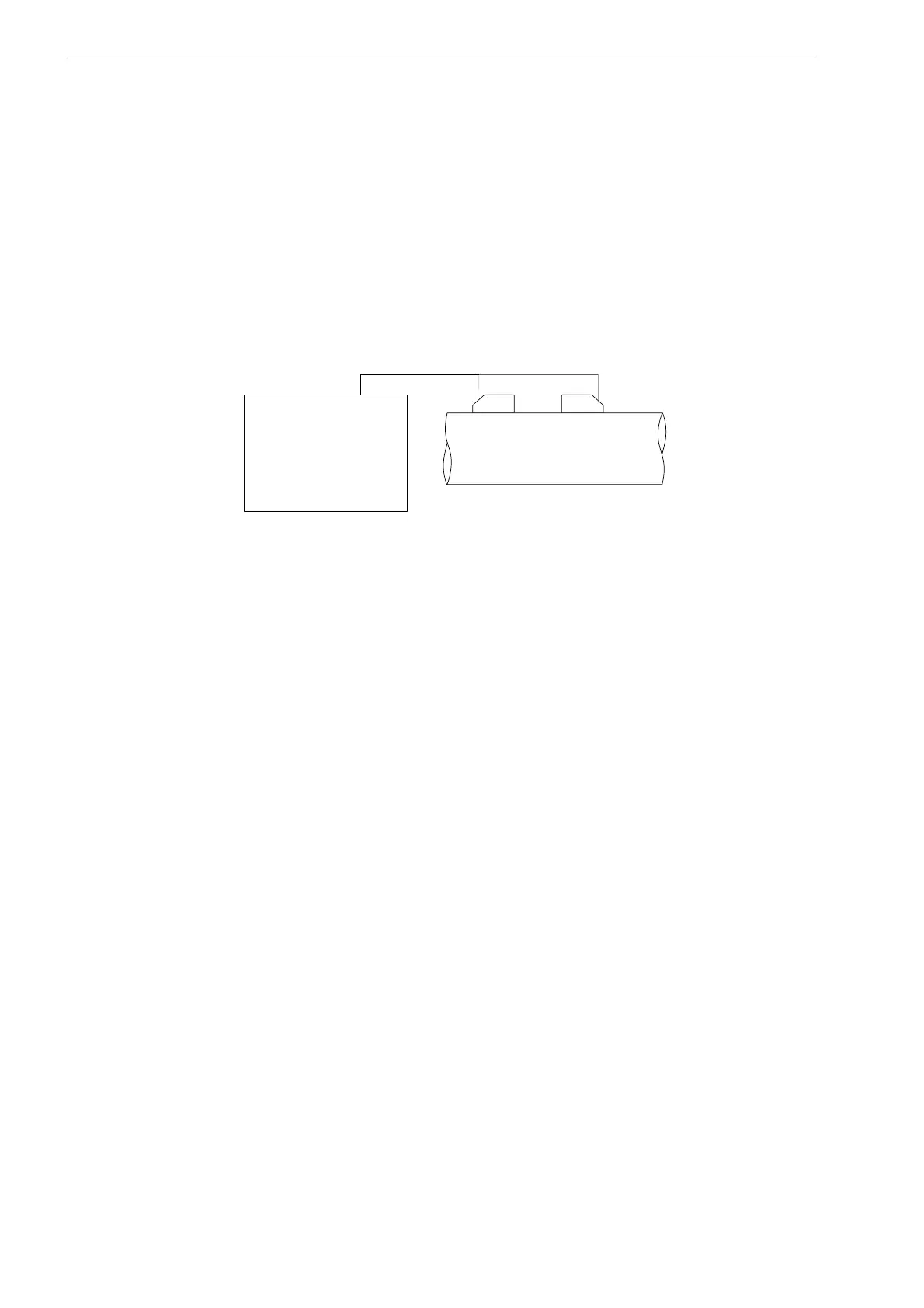

4.1 Measurement system

The measurement system consists of a transmitter, the ultrasonic transducers with the transducer cables and the pipe on

which the measurement is conducted.

The ultrasonic transducers are mounted on the outside of the pipe. They send and receive ultrasonic signals through the

fluid. The transmitter controls the measuring cycle, eliminates disturbance signals and analyzes useful signals. The mea-

sured values can be displayed, used for calculations and transmitted by the transmitter.

4.2 Measurement principle

The flow velocity of the fluid is measured in the TransitTime mode using the ultrasonic-transit time difference correlation

principle (see section 4.2.2). If the proportion of gas or solid particles is too high, the transmitter can toggle to the Noise-

Trek mode (see section 4.2.3).

4.2.1 Terms

Flow profile

Distribution of flow velocities over the cross-sectional pipe area. For an optimal measurement, the flow profile has to be

fully developed and axisymmetrical. The shape of the flow profile depends on whether the flow is laminar or turbulent and

is influenced by the conditions in the supply line of the measuring point (see chapter 6).

Reynolds number Re

Coefficient describing the turbulence behavior of a fluid in the pipe. The Reynolds number Re is calculated from the flow

velocity, the kinematic viscosity of the fluid and the inner pipe diameter.

If the Reynolds number exceeds a critical value (usually approx. 2 300, if the fluid flows in a pipe), a transition from a lam-

inar flow to a turbulent flow takes place.

Laminar flow

A flow without any turbulence. There is no mixing between the parallel flowing layers of the fluid.

Turbulent flow

A flow with turbulences (swirling of the fluid). In technical applications, the flow in the pipe is mostly turbulent.

Transition range

The flow is partly laminar and partly turbulent.

Transit time difference ∆t

Difference of the transit times of the signals. In the TransitTime method, the transit time difference of the signals in and

against the flow direction is measured, in the NoiseTrek mode, the time difference of the signal from the transducer to the

particle and vice versa. The flow velocity of the fluid flowing in the pipe is determined from the transit time difference (see

Fig. 4.2, Fig. 4.3 and Fig. 4.4).

Fig. 4.1: Example of a measurement setup

transducers

transmitter

pipe

Loading...

Loading...