Fliegl Agrartechnik GmbH, 84453 Mühldorf am Inn, Germany

10.4.6 Maintenance of the compressed air brake system

Draining water from the air reservoir:

Every day, the water must be drained from the

compressed air reservoir by pulling on the ring on

the underside.

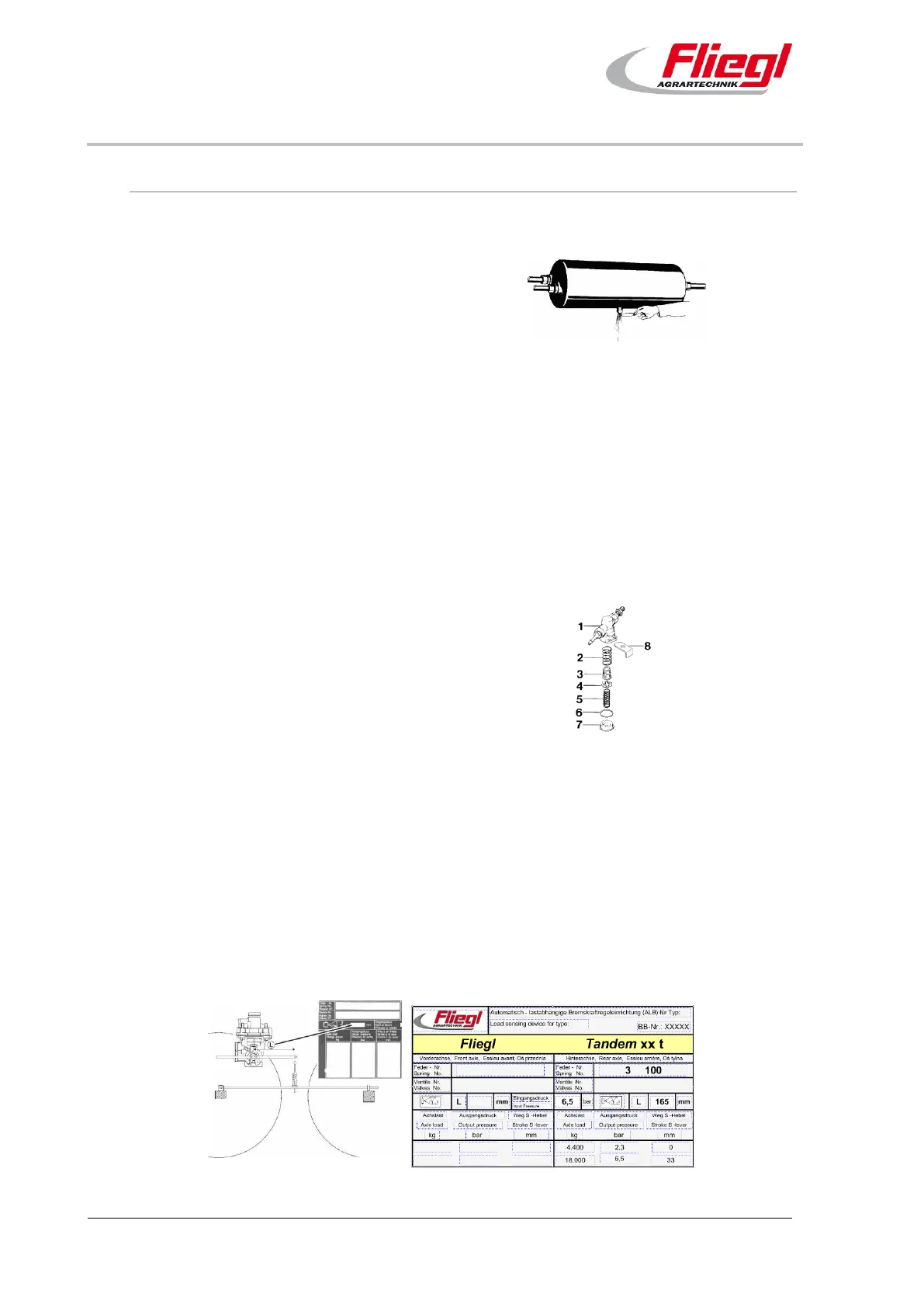

Line air filter

The two filter housings (1) contain sieve inserts (3). If the filter inserts in the line air filters are clogged,

air flows around them without being filtered. As a result, there is no filter protection for downstream

attachments, meaning that the filter inserts must be cleaned at regular intervals.

1. Before opening the filter housing, depressurise the pipes.

2. To clean the sieve filter (3), remove the locking tab (8).

Be aware of the back-pressure from the cap (7).

3. If necessary, rinse the sieve filter with benzine and blow it out.

Always replace damaged sieve inserts and O-rings.

Individual parts of the line air filter see Fig.

1) Filter housing

2) Compression spring

3) Sieve insert

4) Spring plate

5) Compression spring

6) O-ring

7) Cap

8) Locking tab

Fig. 68: Individual parts of line filter

Brake cylinder

Check the brake cylinder. Only up to 2/3 of the brake cylinder stroke should be used.

If this is exceeded, the brake system must be re-adjusted or repaired by a specialist brake workshop.

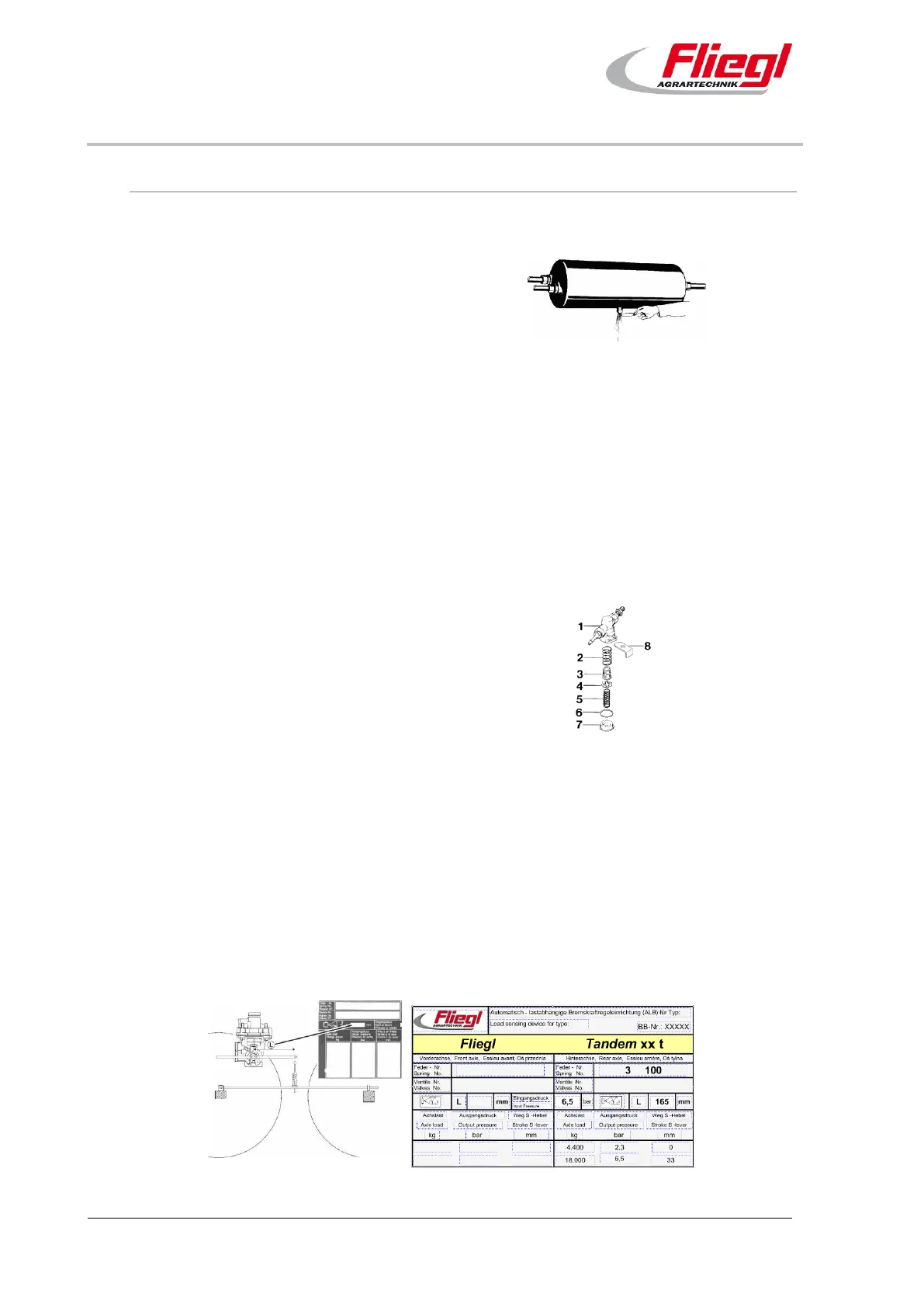

Mechanical ALB regulation

ALB = automatic load-dependent brake force regulation.

The setting length is specified on the ALB plate.

This setting must not be changed.

Fig. 69: Setting length on ALB regulator and ALB plate on the vehicle

Loading...

Loading...