NOSE GEAR COMPONENTS

General

The nose gear consists of an air-hydraulic

shock strut incorporating a self-centering de-

vice, a nosewheel steering actuator, a single

wheel/tire, and mechanically operated doors

(Figure 14-7). The nose strut does not incor-

porate a scissors link.

The nose gear actuator incorporates an inte-

gral downlock mechanism to maintain down-

locked condition; therefore, a downlock pin

is not provided. As with the main gear actu-

ator, the locking mechanism can only be re-

leased by applying hydraulic pressure on the

retract side.

The gear is retracted with positive hydraulic

pressure, then a spring-loaded uplock hook en-

gages the uplatch roller on the forward side

of the strut. When retracted, the nose gear is

enclosed by two doors that are mechanically

connected to, and move with the gear strut.

The uplock hook holds the nose gear up when

hydraulic pressure is relieved after gear re-

traction.

The nose gear uplock can be released by two

methods. The nose gear uplock is hydraulically

operated for normal extension, and is me-

chanically operated via cabling for free-fall ex-

tension.

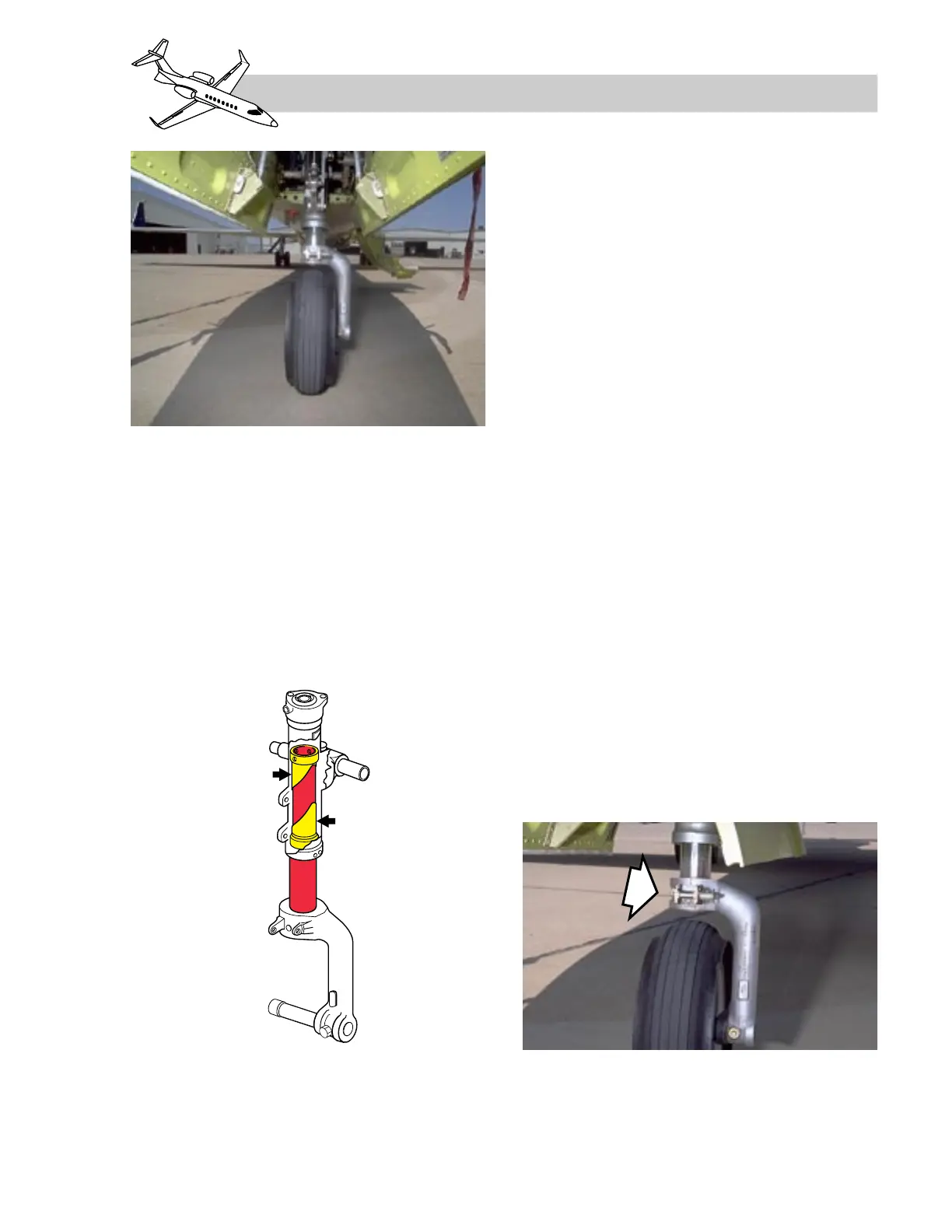

The nose strut incorporates a mechanism to

center the nose wheel for retraction. At liftoff,

two cams within the strut are engaged by strut

air pressure, centering the wheel before it en-

ters the wheel well (Figure 14-8). Also, the

nose steering computer electrically centers

the wheel after main gear liftoff.

Since nosewheel centering prior to gear re-

traction depends on air pressure in the strut,

proper inflation of the strut is important. As

14-9

FOR TRAINING PURPOSES ONLY

LEARJET 45 PILOT TRAINING MANUAL

FlightSafety

international

LEARJET 45 PILOT TRAINING MANUAL

FlightSafety

international

Figure 14-8. Nose Gear Centering Cams

Figure 14-7. Nose Landing Gear

Figure 14-9. Nose Gear Uplock Roller

Loading...

Loading...