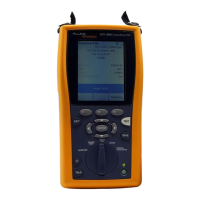

DTX Series CableAnalyzer

Technical Reference Handbook

9-2

Diagnosing Failures

Table 9-2 describes some typical causes of fiber test failures.

-continued-

Table 9-2. Diagnosing Fiber Test Failures

Loss measurement gives FAIL result

•

There is one or more dirty, damaged, misaligned, or unseated connections in the cabling. Check all connections and clean

all fiber endfaces, then retest. The tester’s VFL can reveal damaged connectors and other faults. See Chapter 7 for details.

An OTDR, such as the Fluke Networks OF-500 OptiFiber

™

Certifying OTDR, can help you locate faults not revealed with the

VFL.

•

There is a kink or sharp bend in a reference test cord or the fiber under test. Use the VFL to reveal these faults.

•

A reference test cord is broken.

•

The number of adapters or splices on the Fiber Setup menu is too low (for standards that use a calculated loss value).

•

The wrong fiber type is selected on the Fiber Setup menu.

•

The reference is incorrect. Set the reference again using the same reference test cords to be used for testing.

•

For multimode fiber, the wrong mandrel size was used for testing. Smaller mandrels create tighter bends in the fiber,

resulting in more loss.

•

A reference test cord or fiber segment has the wrong core size. An OTDR is useful for locating mismatched fibers.

•

The cabling has a bad fusion or mechanical splice or a sharp bend. Use the visual fault locator to reveal these faults.

•

The fibers are connected to the wrong ports on the tester, or are swapped at one end of the cabling.

Loading...

Loading...